The manufacturing industry is an extremely competitive and constantly evolving industry, which is why implementing cost-conscious strategies is becoming increasingly necessary! In today’s manufacturing landscape, many businesses approach product cost management as a late stage activity. It’s typically an afterthought, which is why cost management often becomes a reactive approach. In such a case, time-frame inconsistencies and inefficiencies lock in most of the costs early on. Late stage adjustments typically add on to the costs due to expensive redesigns, and compromised timelines. Thus, manufacturers are shifting their focus to cost-conscious design practices right from the start of product development.

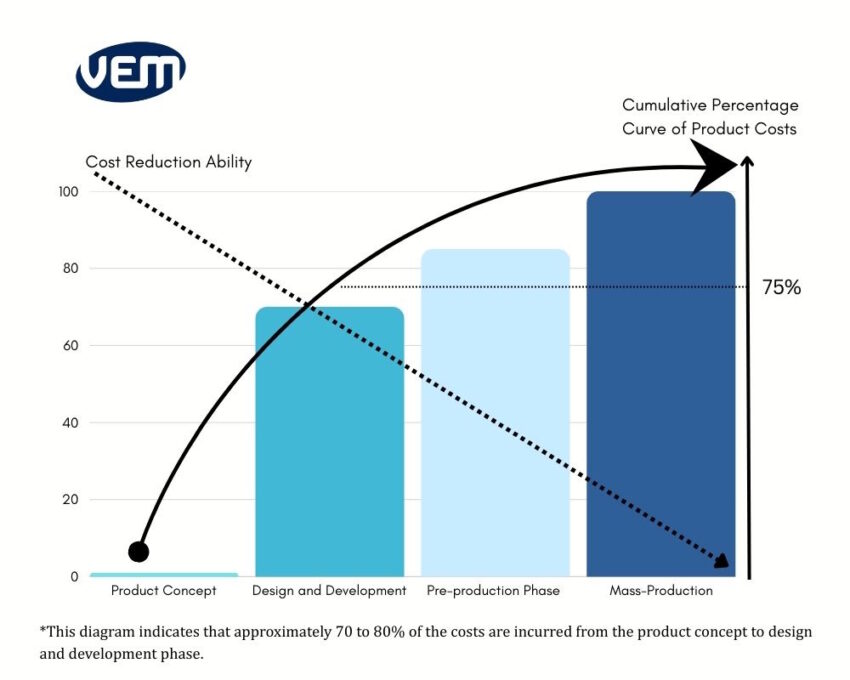

Design for cost enables manufacturers to integrate cost management with decision making in real time. You should note that 70% of the product’s final cost can be determined and optimized during the design stage itself, which is why manufacturing companies today are implementing DFC.

The strategic implementation of cost control at the design stage balances manufacturability with affordability, thereby enabling teams to make informed trade-offs between functionality, performance, and price. In this way, DFC in manufacturing ensures that the cost is not treated as an afterthought, but as a core design parameter that guides every decision along the product’s lifecycle. In this article, we discuss the design for cost in manufacturing, its phases, advantages, and challenges in detail.

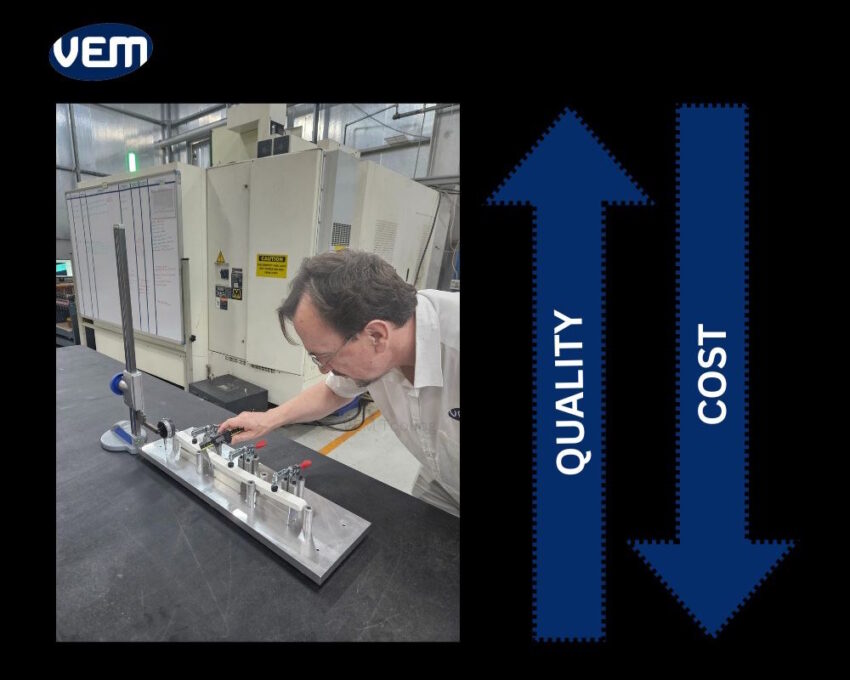

DFC, abbreviated for Design for Cost, is a manufacturing process that aims to integrate cost efficiency into all design process stages. Its main aim is to minimize costs without compromising on the product quality and standards.

Design for cost is a cost management principle that involves a proactive approach to prioritizing cost-specific strategies. It enables manufacturers to set cost targets, design scalable production volumes, and select materials and processes that maximize long-term affordability while maintaining performance. Every design aspect affects the cost and functionality of the design.

The key benefit of implementing DFC in your manufacturing strategy is cost reduction. The above diagram indicates that approximately 70 – 80 % of the product cost is incurred between the product conceptualization and the design and development phase. Implementation of the design for cost solutions can drastically reduce the excessive cost during the mass-production phase. Thus, improving cost-efficiency.

You should note that design for cost differs from target costing, as the former focuses on cost management during the design phase, whereas target costing focuses on broader aspects, such as administration, marketing, etc. In target costing, a specific cost target is set from the start, whereas DFC solutions integrate cost management throughout the design process. Design for cost in manufacturing ensures that the design is adjusted for cost efficiency from the outset.

The first design for the cost phase is to define the target cost of the final product. Manufacturers can identify the target cost by setting up various standards that could range from basic quality to enhanced functionality. This phase enables manufacturers to understand the project scope and requirements.

This is a crucial phase for implementing the design for the cost strategy. In this phase, design experts and engineers identify various cost drivers, which then help them establish an effective cost reduction strategy.

The next phase is the design standardisation phase of the product. In this phase, various aspects of design are considered and accounted for to significantly reduce fixed costs.

This phase enables manufacturers to determine manufacturing decisions. When analysing results, it is imperative to evaluate if the design fits the requirements of the project and if it should be improved upon.

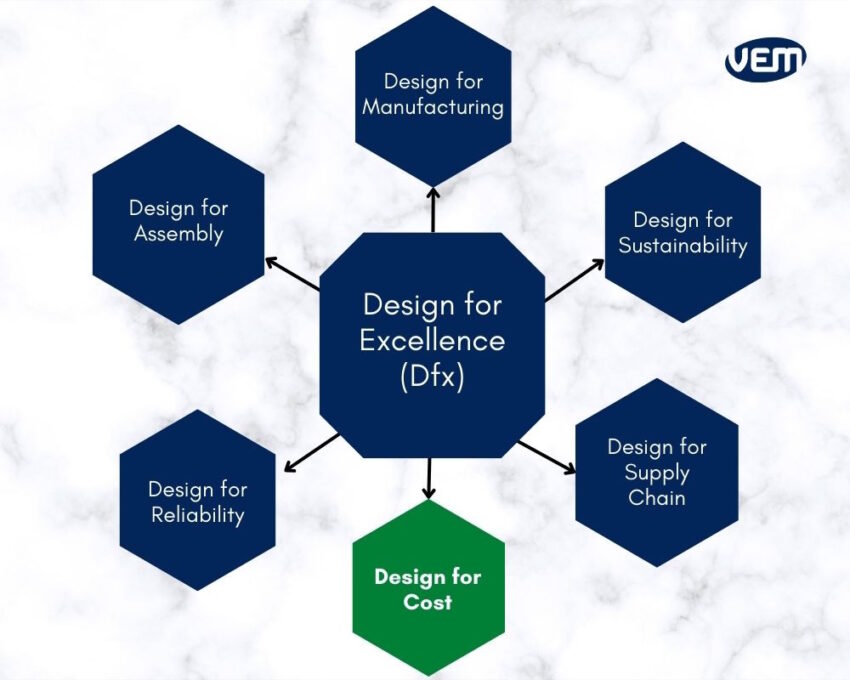

Design for Cost is a vital subset and a foundational element of the Design for Excellence framework. DfX, abbreviated for Design for Excellence, also includes design for manufacturing, assembly, reliability, supply chain, and sustainability. All aspects structure the framework to maximize efficiency and align with project and customer requirements.

DFC is a crucial pillar of Dfx strategy as it helps to reduce risks, improve cost efficiency, and accelerate time-to-market.

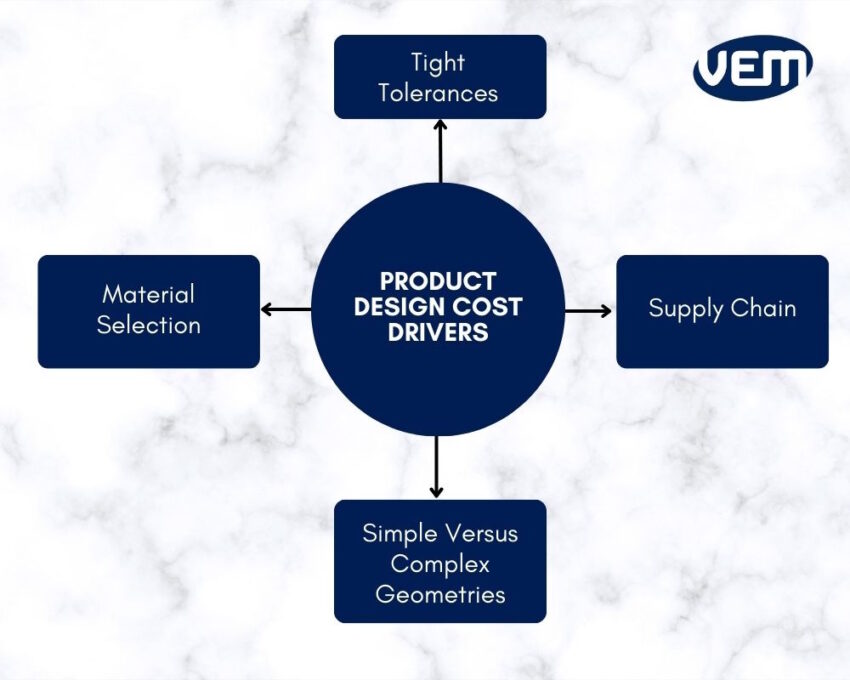

Let’s understand some of the common cost drivers of the product design in this section:

Heat resistant plastics offer flexibility in manufacturing over metals, as they can be manufactured using high-volume production technologies such as injection molding. This enables manufacturers to lower the per-part cost as opposed to their CNC-milled metal counterparts.

Parts with simple geometry have lower costs. Complex geometries, on the other hand, increase costs due to features such as deep undercuts, thin walls, or intricate surfaces. Complex geometry parts typically require custom tooling for manufacturing, which increases the costs. You can read more about custom manufacturing solutions here.

Tight tolerances require particular tooling. If the requirement of precision is tighter, then specialized tooling and high-end machines may be required. These aspects significantly increase production costs.

Material selection is an integral manufacturing aspect. Certain materials are suited for specific applications. If the correct material isn’t applied, then the required specifications may not be met, which can increase the costs.

If the supply chain isn’t efficient, it can lead to an increase in costs. In addition, it can also lead to longer lead times and delays in the supply chain.

To implement DFC strategies for cost-efficiency, design experts must consider optimizing tolerances for functionality. Tight tolerances must be achieved for functional purposes such as fit, strength, or precision and be avoided to achieve perfection as it increases costs.

The next strategy is to integrate multiple functions into a single part. This strategy enables manufacturers to combine various features into a single part. This reduces the part count and assembly, which further enhances cost efficiency.

Another strategy is to simplify part geometries. Complex geometries add to the cost, and thus, an effective strategy is to weigh this against functional complexity or aesthetic requirements.

The first best practice for DFC is to optimize from the beginning i.e., the concept phase. This enables manufacturers to achieve cost-efficiency.

The implementation of a cross-functional team enables manufacturers to incorporate inputs from various aspects and avoid blind spots. A cross-functional team should include, but not be limited to, the manufacturing, procurement, and design engineers.

The next best practice is to implement a CAD-integrated cost analysis software or an equivalent system that gives real-time insights during the design and development phase. Such systems and software must be tailored to enable the implementation of DFC strategies.

Collaboration with supplier partners from early on enables manufacturers to identify potential cost drivers. Supplier partners provide valuable insights and cost estimates to manufacturers. It is recommended to establish lean manufacturing strategies to support the implementation of DFC in manufacturing.

The next best practice for implementing the design for cost strategy should be to conduct a lifecycle cost analysis, which provides a comprehensive view of the costs involved. The lifecycle cost analysis evaluates the complete cost of the part.

Just like most plastic materials, heat resistant plastics are broadly categorized as amorphous and semicrystalline. In this section, we discuss these two categories and various types of heat resistant plastics.

DFC identifies cost drivers early on, during the design stage, thus, enabling manufacturers to avoid unnecessary complexity, excess material use, and inefficient processes. This proactive approach prevents expensive rework and minimizes waste across the lifecycle.

The implementation of DFC strategies in manufacturing streamlines development cycles and reduces bottlenecks. It thus accelerates the journey from concept to customer delivery.

Design for cost improves collaborations across functions and encourages the involvement of various teams to align on cost targets. Cross-functional teams such as design, engineering, procurement, and suppliers share responsibility thereby improving the transparency and reducing the risk of overlooking hidden costs.

It’s easier to scale the production run when cost efficiency is completely accounted for. Manufacturers can adapt quickly to increased demand without spiraling costs through material and process standardization.

Implementing cost control can be met with resistance to change. You should note that teams may resist the shift from traditional workflows, and thus, its implementation may require change management.

Design for Cost strategies may require the integration of certain software, simulation platforms, and training. These upfront expenses are an initial investment.

DFC strategies can be disrupted by supply chain volatility. They must be flexible enough to absorb external uncertainties such as fluctuating material prices or supplier instability.

Design for Control improves the cost-efficiency of product design and development.

VEM Tooling has over 20 years of experience in tool building and manufacturing high-quality parts. Our experienced engineers can guide you throughout the Design for Cost process and other manufacturing solutions, such as injection molding and tool building.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.