Draft angles are a design requirement of injection molding and are considered among the best practices for plastic injection molding. Injection molded parts are required to be ejected from the mold which is why the parts mustn’t incur any damage or defects during ejection. To avoid the same, draft angles are incorporated. If the draft angles are inadequate, it can compromise the fit, functionality, and aesthetics of the part.

Draft angles are a key design feature that helps manufacturers achieve high-quality plastic parts at a competitive cost. You should note that more than 95% of injection molding designs require draft angles to manufacture a high-quality part. In this article, we discuss draft angles, their significance, and design considerations in detail.

Draft angles are typically a requirement for successful part production. They are an integral component in facilitating an efficient, high-quality part manufacturing process.

A lack of draft angles in the mold design can lead to issues such as longer cooling times, and injection molding defects. Draft angles are simply one component of a well-designed part but it is one of the easiest ways to improve the quality and efficiency.

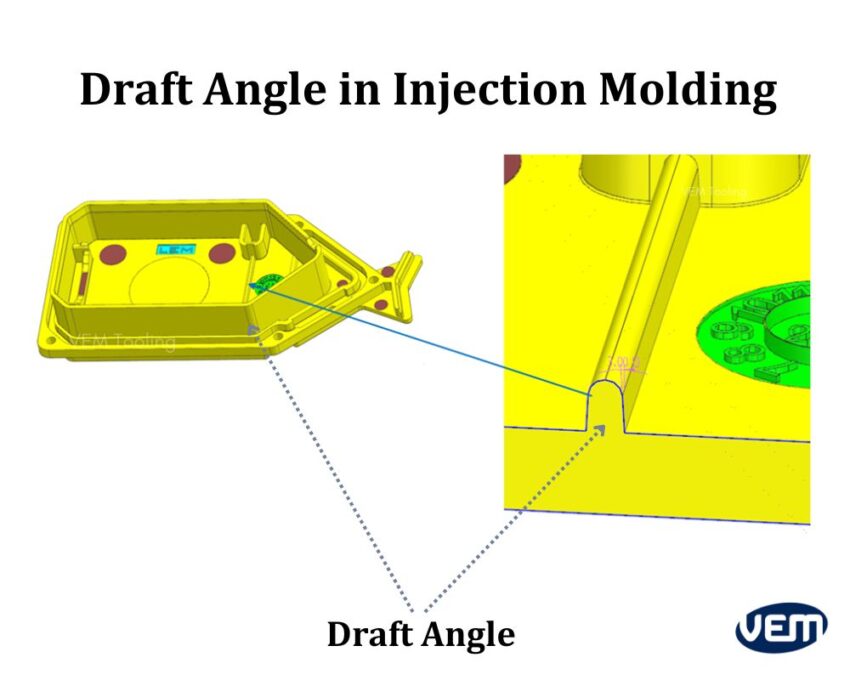

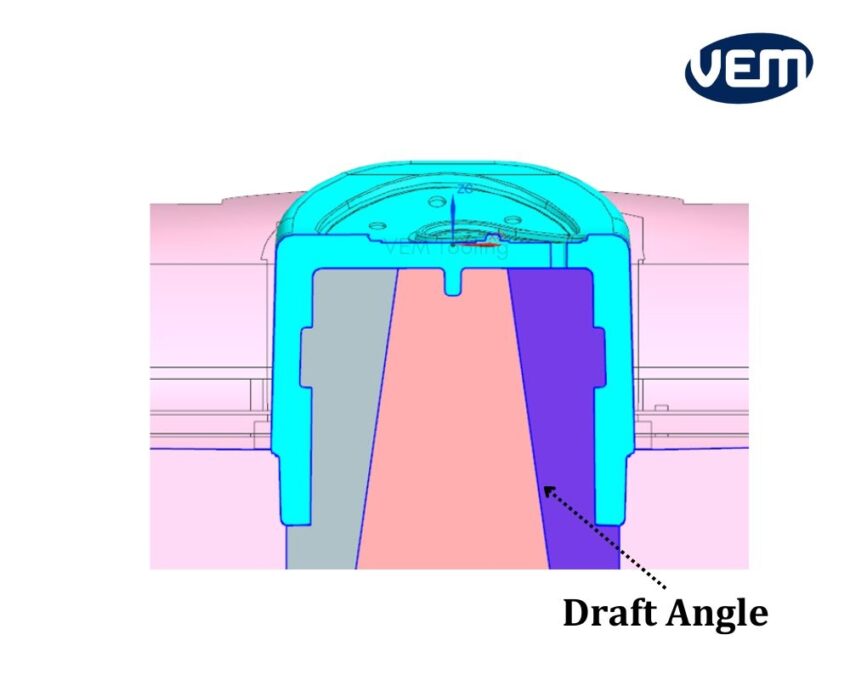

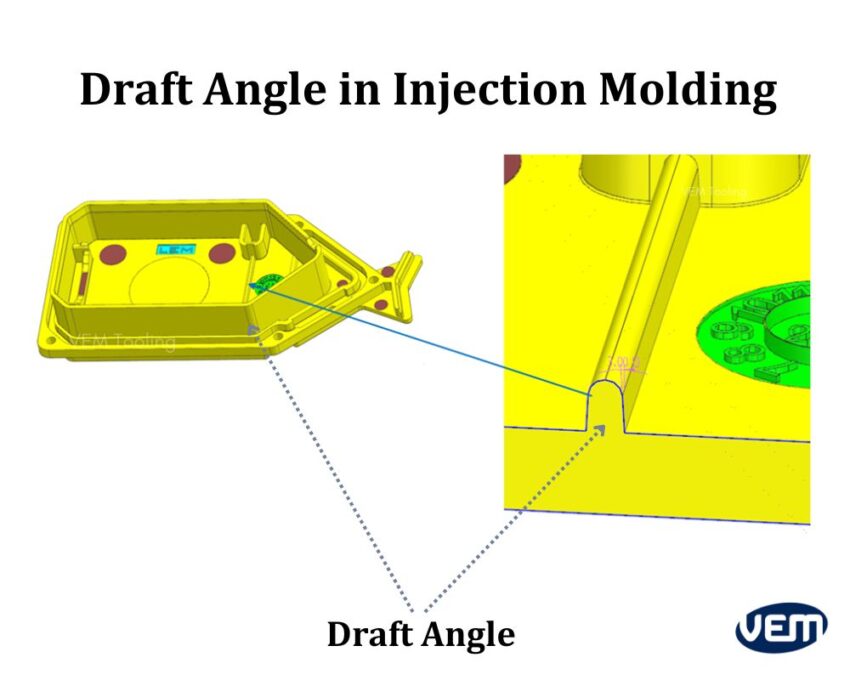

A draft angle is a tapered slant, applied to the sides of the injection-molded component. It helps to efficiently and easily release the parts from the mold.

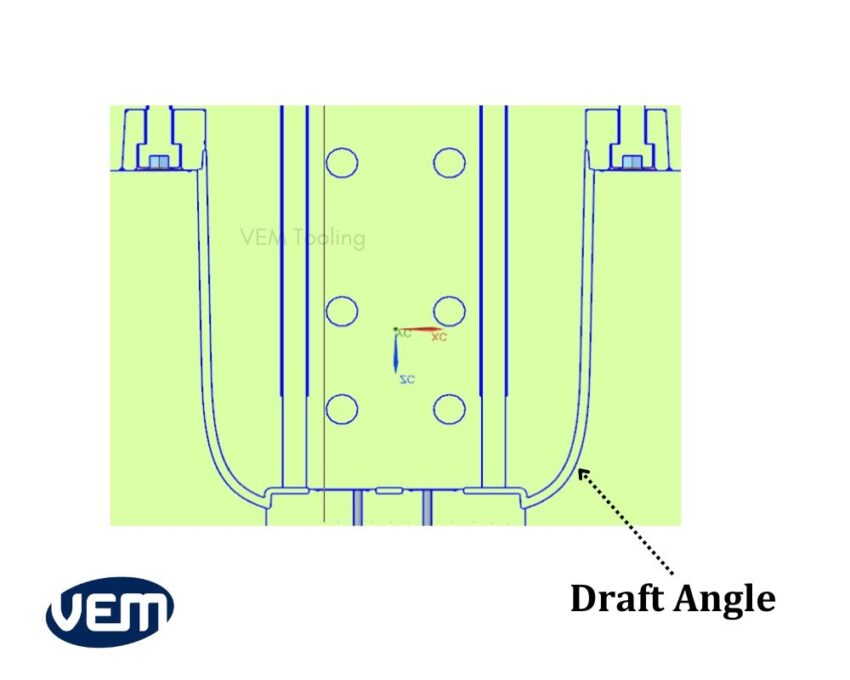

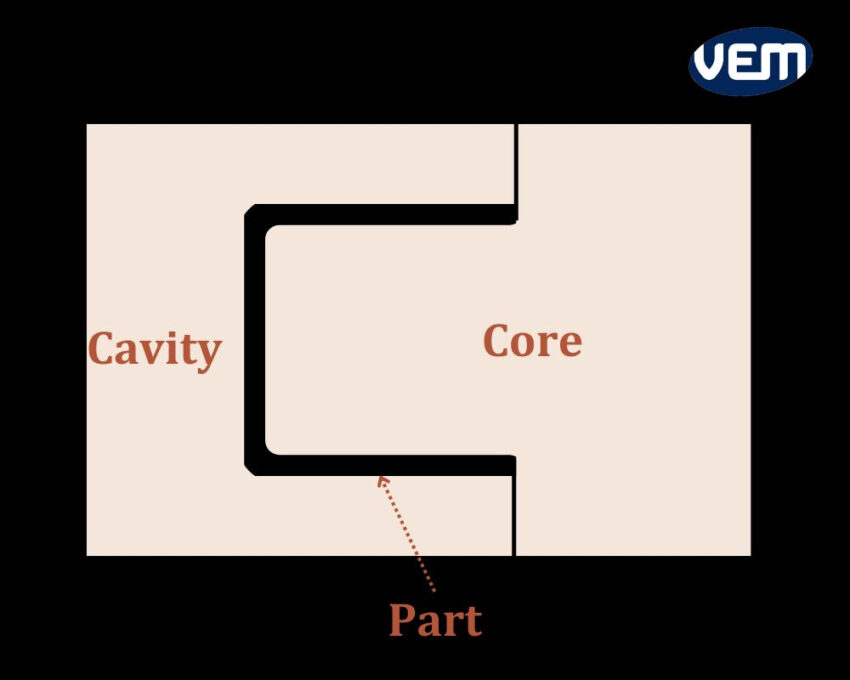

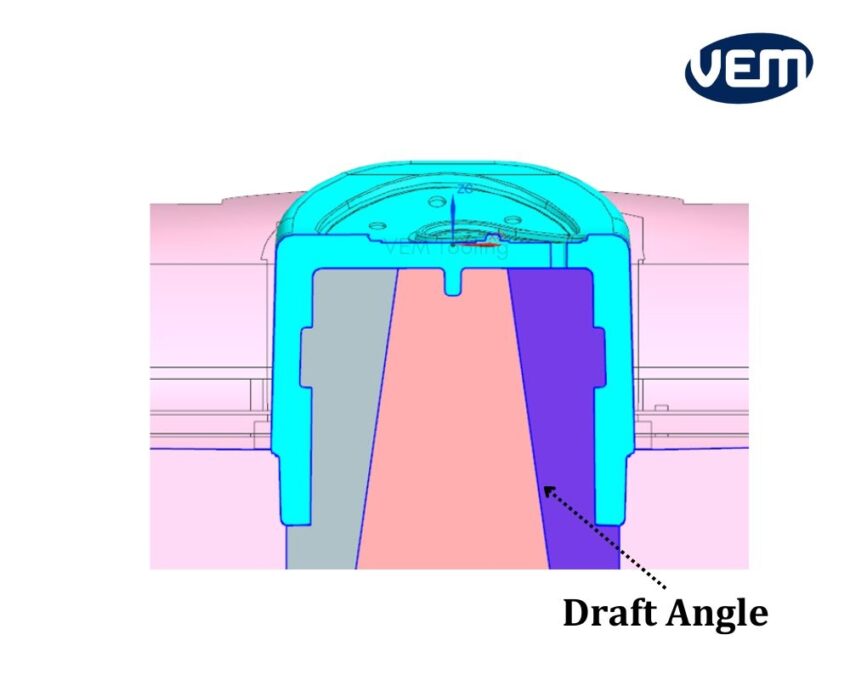

A mold has a hollow side i.e. the cavity, and on the opposite side is the core. To facilitate the ejection of the part from the mold, it is necessary to set an angle on the part’s surface that is parallel to the release direction. This particular angle is referred to as the injection molding draft angle. When the angle is tapered on the molded part’s surfaces, the part can easily slide across the mold’s cavities and cores during demolding. A draft angle is a measurement of degree from the vertical axis of a mold and is typically designed and modified on the reference model.

Let’s understand some general technical guidelines for implementing draft angles for your injection molded parts

Draft angles must be incorporated early on in the design process even when the draft angle is not required. It can be incorporated as early as when prototyping with 3D printing or CNC machining processes.

Draft angles alter the form and fit of a part. They also transform to affect the aesthetics of the part. Thus, If a prototype design will move towards mass production, it should include the draft angle in the design even if it’s not technically required. Integrating draft angles into early prototypes avoids redesigns and any type of additional prototype development. Thus, the draft angle should be incorporated from the very beginning during the plastic injection molding product design process.

Draft angles account for thermoplastic shrinkage that typically occurs during the cooling of the injection molding process. This helps to reduce friction between the finished, cooled part and the mold side, creating an easier release process.

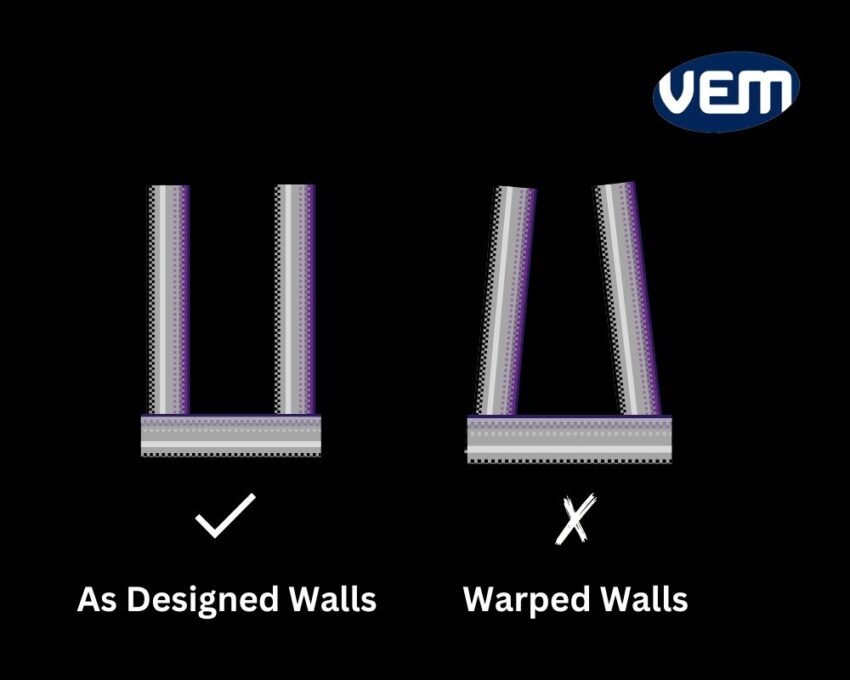

Draft angles minimize plastic warpage by overcoming the vacuum to let the air between the part and the mold to release the part correctly. Thus, incorporating an adequate draft angle ensures that the warpage is prevented while maintaining a smooth surface finish upon ejection.

The line of draw is the point where the two halves of the mold separate to release the part. You should note that the depth of the draw impacts how easily the part will be released. The risk is lower with shorter draws whereas higher with longer draws. Draft angles reduce the deep draw thereby, helping to release the parts more easily.

Parts that don’t eject well from the mold are prone to damage. You should note that aggressive forces stress upon the part, leading to damage and defects during part ejection.

Parts can also get stuck in the mold which not only damages the mold but also increases the costs, time, and various other resources. A well-designed draft angle reduces or eliminates these forces to reduce operational risks, cycle times, and costs.

If the draft angles are inadequate, the part may drag on the molded surface when the mold ejects the parts, thereby creating surface finish scratches on the part. Draft angles reduce the friction during release thereby facilitating smoother ejection thus, enabling manufacturers to achieve a smooth and unscratched finish.

Draft angles also prevent the mold from undergoing any unwanted wear and tear. Without any taper, the mold life can be shortened due to mold damage.

If the part is designed such that it can be easily released, then it is easier to eject the part, thus giving room for including more cooling channels.

Draft angles enable manufacturers to replace pins and sleeves to eject the part with more cooling channels which further, helps to cut down costs and cycle times. This is especially beneficial for high production volumes.

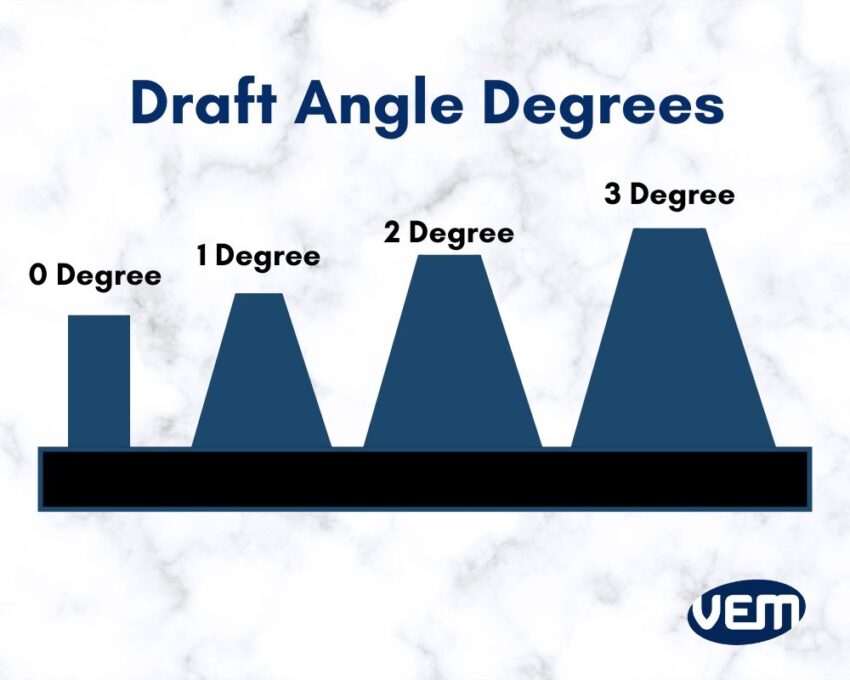

A draft angle is calculated as a degree measurement however; in some cases, it is also measured in the form of millimeters or inches.

A standard draft angle is about 1° to 2° and when high dimensional accuracy is required, a draft angle of about 1/2° to 1/4° is applied.

In general, a minimum of 1 degree of draft angle is recommended per inch / 2.54 cm of mold cavity depth.

The draft angle size is expressed in terms of tilt angle or taper when it’s symmetrical and is broadly classified as follows:

Every part has unique injection molding requirements and such is the case with draft angles as well.

The draft angle size is impacted by the shrinkage rate, friction factor, wall thickness, and part geometry. We have listed below some pointers for the draft angle design consideration:

If the draft angle negatively impacts the part performance, it can be designed with a draft angle of 0.25 to 0.5 degrees. The small degree of draft angle is better than the zero draft angle.

The draft angles must be towards both sides of the cavity and core. This reduces the risk of part damage during ejection. When the molten resin flows into the closed mold and fills the cavity, the material shrinks inside the mold as it cools, and the cooling shrinkage exerts some clamping force on the mold core. When the draft angle is inadequate, the mold’s wear and tear increases thereby, shortening the mold’s life. In addition, if the part doesn’t eject, the production will need to be stopped and the parts will need to be manually removed.

Incorporating draft angles in your design is one of the best practices for injection molding. Draft angles are a necessary feature to manufacture a well-designed part. Our team at VEM Tooling, encompasses experienced engineers that can guide you with the correct manufacturing solutions for incorporating draft angles for your project.