The manufacturing industry is constantly evolving, and during this fast-paced evolution, it needs to ensure that the manufactured products meet the customer specifications and regulatory requirements. In order to ensure that the product quality is consistently as per the specifications, there are various quality management systems, and one of them is referred to as FAIR, abbreviated for First Article Inspection Report.

First Article Inspection Report ensures that quality objectives are met at the initial stage of production. An effective first article inspection process provides documented evidence of compliance and enhances traceability and efficiency within the production cycle. In this article, we discuss the first article inspection process, explore the structure of a first article inspection report, and discuss its various types in detail.

A first article enables businesses to validate if the supplier is capable of manufacturing parts that meet all the design and engineering requirements. The first article is basically the first part that is manufactured through the same production processes by the supplier or contractor.

First articles are parts that are selected randomly, which are then considered as samples for the production run. The analysis of the first article enables manufacturers to identify issues early on in the manufacturing process. It also ensures quality assurance and builds customer confidence.

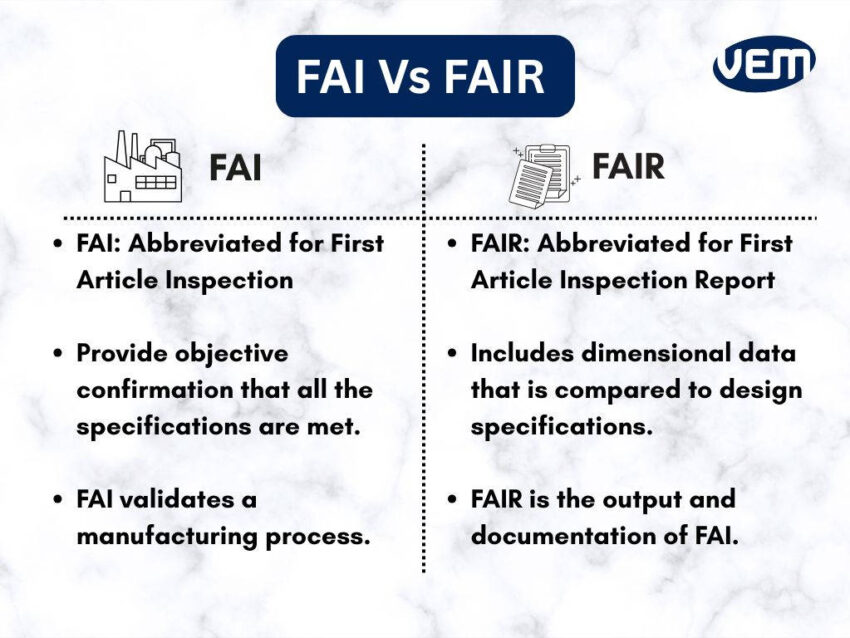

First article inspection, abbreviated as FAI, is a manufacturing process that ensures that every requirement and process is up to the mark before the entire production begins.

FAI is comprehensive in its initial checks and documentation of the first item. It can be implemented for new products or existing products after major changes have been introduced to the design. FAI also verifies the viability and performance of the manufacturing setup.

FAI has various advantages, but you should note that it isn’t a mandatory process in the manufacturing landscape. It isn’t advantageous to carry out FAI if the batch is extremely small. You should also note that though it can be applied to various industries, it is more commonly applied in high-precision industries where production failure can incur increased costs. For instance: Medical Devices, Aviation, Defense, and Automotive industries.

In FAI, it is imperative to ensure that all requirements are met by inspecting a random sample of the first production run. During FAI, typically, every dimension and the specification of the sample are verified against the drawing before the complete manufacturing process begins.

First article inspection involves testing and inspecting the first part or sample parts that are manufactured in a batch. The number of parts is dependent upon the order size. Typically, 3–5 units are selected at random for a large production run, and if the batch is small, then only one unit may be sufficient.

The scope of the first article inspection includes a checklist, raw materials, components, and processes. Let’s understand the scope of the first article inspection in detail:

The first aspect is creating a checklist. A checklist is typically created by the quality assurance team or the supplier and ensures that each and every aspect is included.

The second aspect of the first article inspection is evaluating the raw materials that are used in the manufacturing process. It involves analyzing the properties of raw materials to understand their behaviour under different environmental conditions.

This step includes ensuring that not only is the quality of the materials apt, but it also meets all the specifications and the requirements of the desired application.

First article inspection includes inspecting every equipment that will be involved in the production process.

In addition to the raw materials and equipment, the manual or automated assembly processes are also inspected. This stage ensures that all parts assemble correctly.

The final stage of the first article inspection scope is to ensure that the finished part or the product meets all the specifications and is free of any defects. It is thus thoroughly inspected to ensure that it meets all the quality requirements.

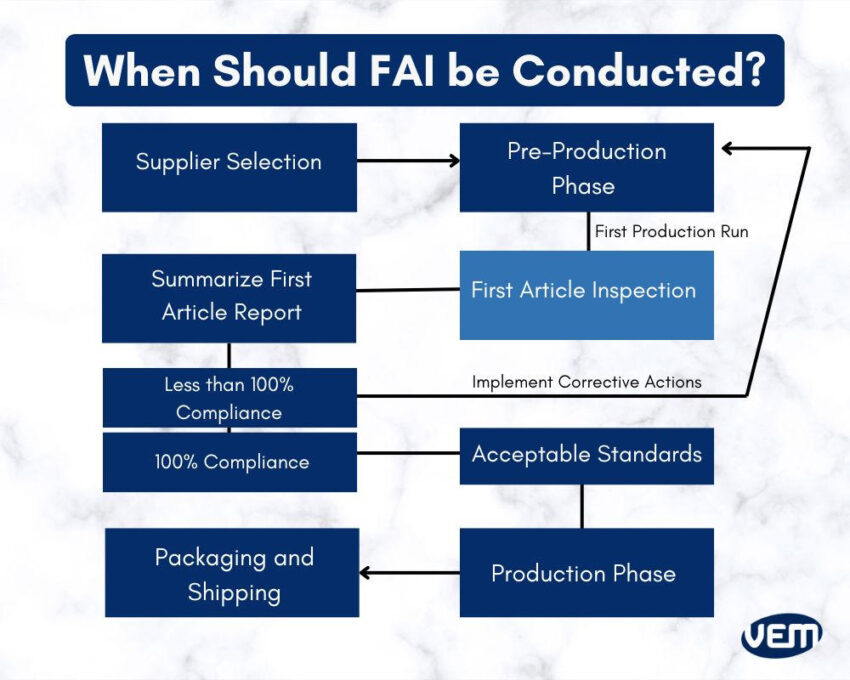

The first article inspection is conducted during the pre-production phase, which is also referred to as the first production run.

The first article inspection confirms that all criteria are met and everything is as per the expectations. If there are no findings in the FAI, then the production phase can begin.

However, if compliance is less than 100%, then the manufacturing operations are paused, and a corrective action is applied. Post the corrective action, the first article inspection is conducted again.

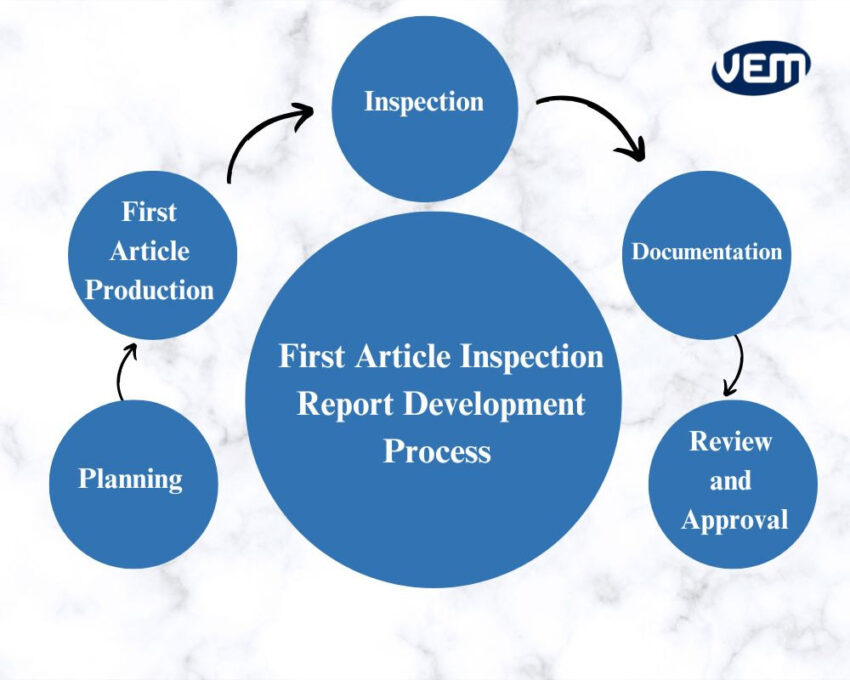

The following diagram illustrates the process flow:

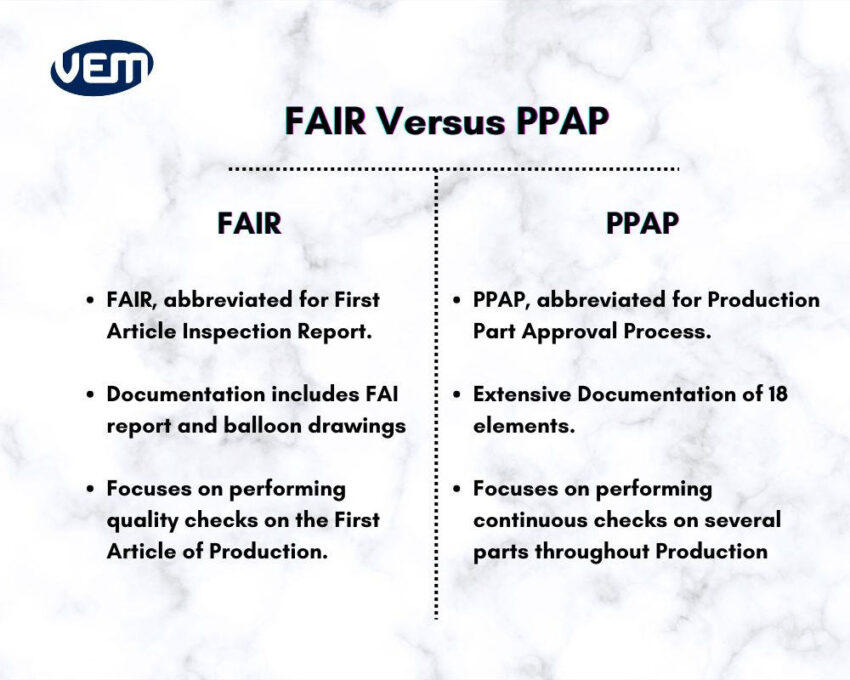

FAI isn’t mandatory, but it is an integral aspect of quality management systems. First article inspection serves a similar purpose within quality management systems as the Production Part Approval Process, abbreviated as PPAP, but you should note that they are two distinct quality systems. They share a common objective of process validation and are both part of the APQP, abbreviated as Advanced Product Quality Planning framework, in different industries. Both processes require documentation that provides evidence of conformance however, they are distinct from each other. The following infographic demonstrates key differences between FAI and PPAP:

You can read more about PPAP here.

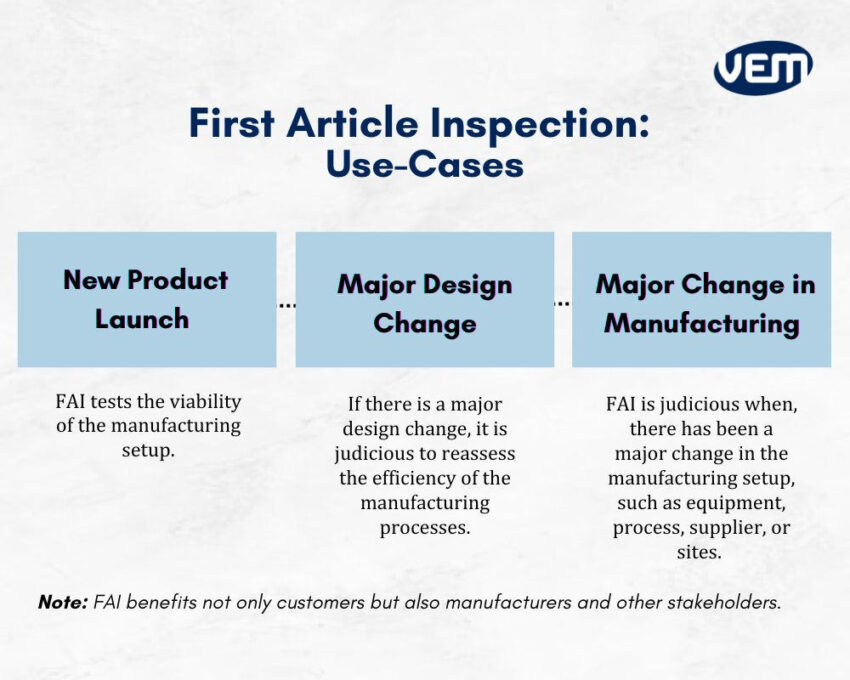

FAI has various use cases. It benefits customers, manufacturers, and various other stakeholders. It’s typically applied under the following case scenarios:

FAI is especially applied during a new product launch. It tests every aspect of the process. FAI tests the viability of the manufacturing setup.

Another use case of the first article inspection is when there is a major design change during the production stage. If there is a major design change, it is judicious to reassess the efficiency of the manufacturing processes via first article inspection processes.

A major change in the manufacturing setup can have a huge impact on the product quality. It is thus judicious to incorporate the first article inspection process when there has been a major change in the manufacturing setup, such as equipment, process, supplier, or sites.

Typically, extensive quality checks are performed at the end of the production; thus, most quality issues are only identified after the manufacturing is complete. First article inspection ensures that an initial quality check is performed, which indicates any issues early on.

The first article inspection report builds confidence in the manufacturing processes of the production line through validation. It identifies errors and issues early on. This helps to minimize costs and reduce product callbacks. It thus ensures that the production process is reliable and repeatable.

Companies have to follow several industry standards. First article inspection enables manufacturers to comply with these industry standards through evaluation and reporting.

The first article inspection report is submitted before beginning a batch, which improves customer satisfaction and indicates that the manufacturer is focused on delivering high-quality parts, thereby improving the manufacturer-customer relationships.

The First Article Inspection Report, abbreviated as FAIR, is a comprehensive overview of the first article’s quality. It helps to analyze the performance of the manufacturing process and validate the production process.

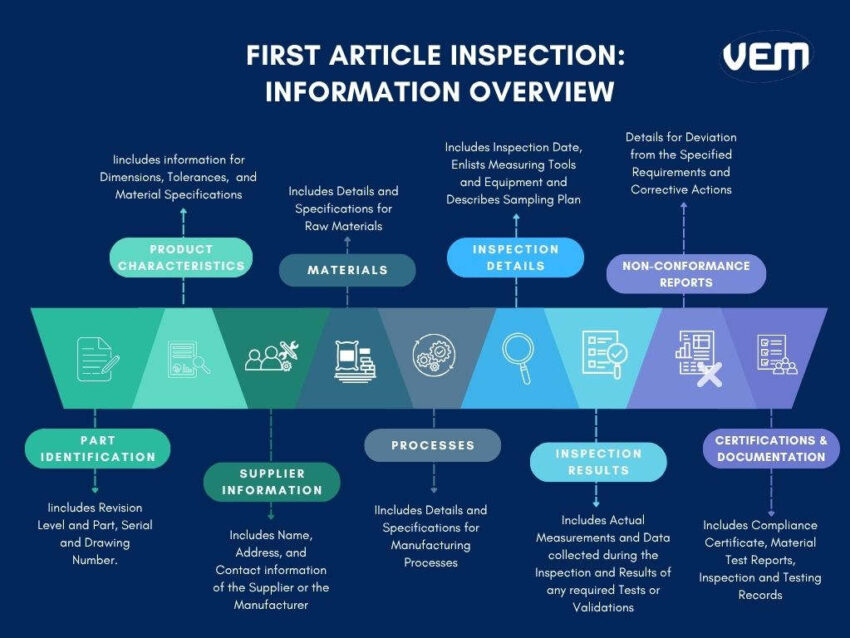

A First Article Inspection Report is an extensive document that indicates the procedures of testing, part identification, and several details. The infographic below gives an overview of the information that is typically covered in FAIR:

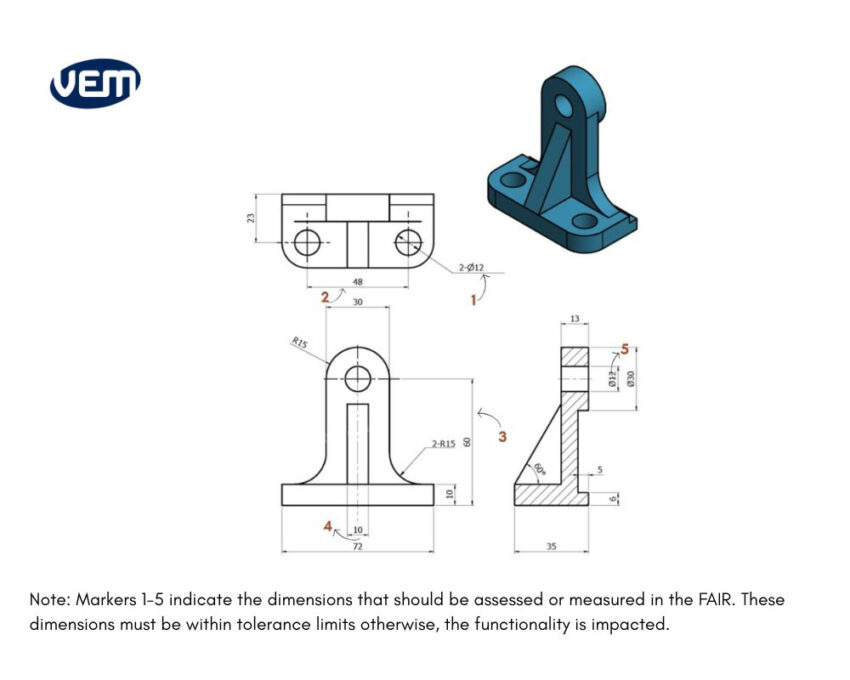

The diagram below indicates the dimensions of the part that should be assessed or measured in the FAIR. These dimensions must be within tolerance limits otherwise, the functionality is impacted.

In this diagram, markers 1-5 indicate the dimensions.

The First Article Inspection should be conducted by an authorized person, i.e., either the supplier or a contractor.

A first article inspection is typically carried out by the supplier and is usually agreed upon in the purchase order. It’s a level of quality assurance that’s provided by the supplier. In certain cases, the supplier may not have an in-house facility for conducting a first article inspection, and in such cases, the first article inspection may be outsourced for evaluation.

First article inspection is an extremely systematic and organized process. Let’s understand the various steps of the first article inspection process:

The planning stage involves enlisting the requirements of the first article inspection. At this stage, the design experts and engineers define the industrial standards that need to be adhered to. They also define the processes that are to be included and draft the balloon drawings in the planning stage.

In this stage, the first article is produced, which may either be the very first article or an article from a particular batch.

The next stage is the inspection stage. At this stage, the first article inspection equipment is employed to verify part dimensions, material properties, and other characteristics.

The next stage is to draft the first article inspection report. This documentation consists of all the necessary details of the process procedures and results.

The review and approval stage is the final stage, and it involves a detailed check of all the activities. The report is approved if all the details are satisfactory.

The First Article Inspection Reports are of several types or formats. This is largely dependent upon the industry standards, customer requirements, and regulatory guidelines. Let’s understand the various types and their documents further:

The AS9102 first article inspection report follows the SAE AS9102 standard and is typically employed by the aerospace, defense, and aviation industry. In this report, every aspect is verified. It includes the following documents:

The part number accountability form is an introductory form. This form documents the part being inspected during the FAI process. It also includes its unique identification and any of its detailed parts or related sub-assemblies.

Product accountability form documents various details about raw materials and processes. It also lists if there are any functional tests that are associated with the manufacturing of the part.

This particular document ensures that apt and up-to-the-mark material and processes are being implemented.

Characteristic accountability form records the dimensional inspection results. It summarises design characteristics, such as tolerances, measurements, drawing notes, etc. Characteristic accountability form also requires a balloon drawing:

A balloon drawing is also referred to as bubble drawing. It’s like an appendix and supports the characteristic accountability form of the first article inspection form.

A balloon drawing verifies every design characteristic requirement. In this type of drawing, the design characteristics have a uniquely numbered balloon that must match the characteristics numbers on Form 3.

A custom or in-house first article inspection report is a tailored report that is created for client-specific purposes by manufacturers to match the internal quality processes.

This type of report enables flexibility and is ideal for industries that don’t require AS9102 but still need a comprehensive documentation that’s thorough and robust.

A custom report typically includes the following documents:

A supplier’s first article inspection report is generated by the supplier. This type of inspection report ensures that the part complies with the purchase order and the quality requirements. It’s mainly used for supplier validation and is incorporated by companies with outsourced manufacturing. This type of document maintains consistency and quality across supply chains.

A supplier’s first article inspection report includes the following documents:

This type of report focuses only on the dimensions. It verifies the physical dimensions of the part using tools such as calipers, micrometers, or a coordinate measuring machine. It excludes any type of material certifications or functional tests.

It’s typically used when geometric accuracy is critical, but other aspects such as the material or surface finish remain unchanged.

If the changes are very targeted, i.e., in design, material, or process, then this type of report is incorporated. It’s efficient and targeted as it does not require repeating a full FAI. A Delta or Partial FAI focuses only on the areas that are impacted by the change, which saves time and keeps records relevant.

This type of report includes the following documents:

Every project guarantees a transparent FAIR according to our customers requirements. With over 20 years of experience in manufacturing and tool making, we know exactly what is important and are happy to identify which are the critical dimensions for your part.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.