There are various types of materials that are used for manufacturing high-quality plastic parts through injection molding techniques. Thermoplastics such as ABS, PEEK, PC, and PA i.e. Nylon are some of the popular choices that are incorporated by an array of industries to manufacture various products.

When thermoplastics are combined with glass, they become much stronger and they develop unique properties. Their variants such as glass-filled polymers have been popularly considered for manufacturing as they are comparatively much stronger than their natives. Polyamides are significantly strong by themselves and, when glass is added, the qualities of rigidity, strength, and hardness are enhanced.

Such is the case with glass-filled Nylon as well. In this article, we discuss such unique properties of glass-filled nylon, its variations, and how it is used to manufacture high-quality plastic parts via injection molding techniques.

Before we dive into glass-filled Nylon, let’s first understand the base material i.e. Nylon. Nylon is a brand name for the ‘generic’ polyamide and is typically derived from non-renewable petroleum.

Nylon is a semi-crystalline polymer that can be modified to have distinct properties. Due to this versatility, it can be applied to an array of industries. It is very popularly used in the textile and food packaging industry. You can read more about Polyamide or Nylon injection molding here.

Glass-filled nylon, as the name suggests, are nylon types that are reinforced with glass fibers.

Glass-filled Nylon is a modified version of Nylon that is primarily a composite material. It’s a synthetic polyamide thermoplastic with the morphology of short glass fibers suspended within a nylon matrix. These glass fibers reinforce the polymer to increase its strength! This amalgamation of nylon with glass fibers gives distinct properties to the material such as added stiffness, strength, and durability. These properties make it unique and an ideal material for manufacturing plastic parts that need to withstand high stress! Glass-filled nylons also have a low coefficient of friction, which makes them excellent material choices for sliding applications.

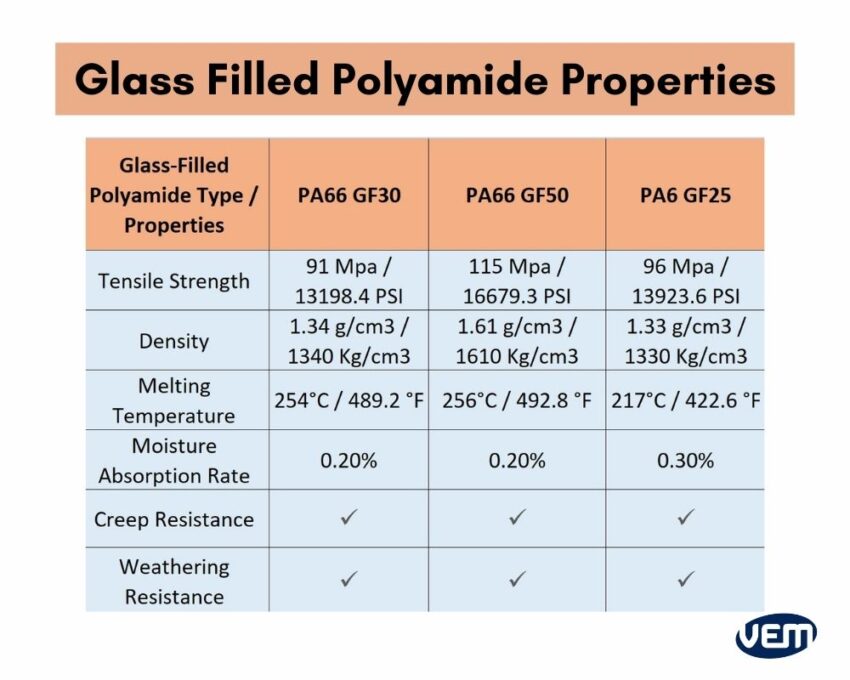

Glass-filled nylons are extremely popular due to their versatility. Today, Polyamides are mixed with glass fibers in various proportions to create unique blends. There are various grades available and most of them are either based on Nylon 6 or 66. Let’s take a look at some of the popular glass-filled polyamide / Nylon blends:

PA66 GF30 is a composite material where polyamide 66 is reinforced with 30 % glass fiber. This blend demonstrates outstanding mechanical properties such as higher strength, dimensional stability, and exceptional creep resistance. PA 66 GF 30 also exhibits high thermal stability, such that glass fibers are able to hold the nylon matrix at elevated temperatures.

PA 66 GF50, is formed when polyamide 66 is reinforced with 50% glass fiber. It’s based on a partially crystalline polyamide with some aromatic components. This modification and increase in glass fibers give the composite the ability to withstand extremely high temperatures of approximately, 130°C / 266°F. In addition to high-temperature resistance, PA66 G50 exhibits high strength and rigidity, low warpage, excellent chemical resistance, and dimensional stability.

PA 6 GF25 is polyamide reinforced with 25% glass fiber content. This blend has a reduced glass content which allows for shape extrusions with larger dimensions. It exhibits high levels of stiffness, strength, and rigidity.

Glass-filled Nylon can be made through various procedures. Let’s take a look at the different types of glass that can be embedded into the nylon matrix to create the material.

The amount of glass that is mixed into the Nylon base is controlled and thus, various blends of glass-filled Polyamides are formed. These are mixed into the nylon via the extrusion process. The extrusion process increases the material’s strength and is a manufacturing molding process that involves forcing the base material (in this case, Nylon) through a pre-shaped die to create a specific profile.

You should note that Nylon 6 and 66 are one of the most common bases for producing glass-filled Polyamide variants.

If you’re seeking a manufacturing material that can deliver superior performance and durability, then you should check glass-filled Polyamides as an option for your projects. These composite blends have unique properties that set them apart!

You should note that there are various types of glass-filled composites due to which the properties may vary. The below table demonstrates the properties of the various glass-filled Polyamide blends. Let’s take a look at the physical, chemical, and mechanical properties of these composite blends:

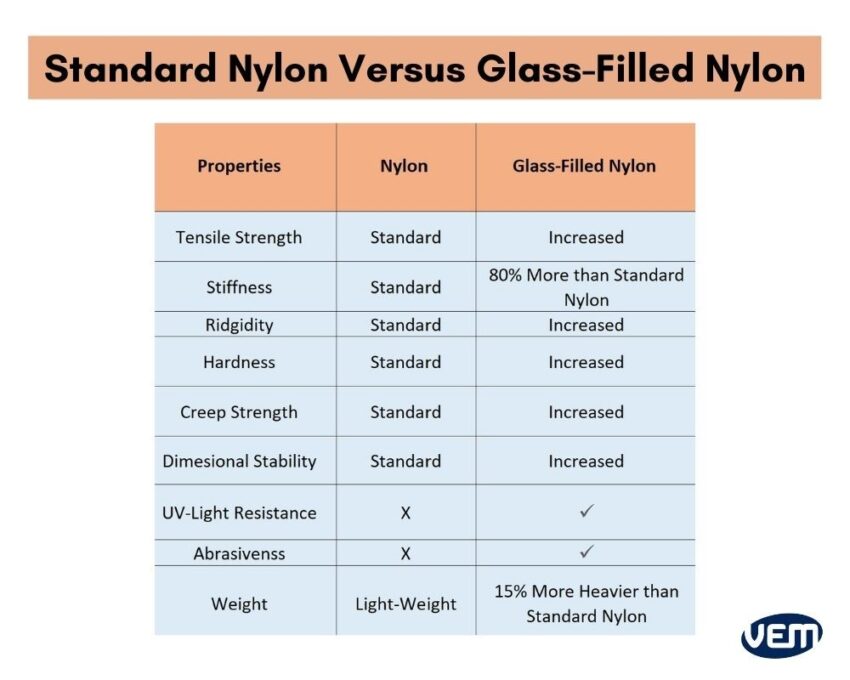

Glass-filled Nylon is superior to standard Nylon in that they have higher tensile strength, greater rigidity, and better toughness. They also demonstrate excellent thermal stability, chemical resistance, and dimensional stability under long-term stresses. Let’s take a look at the similar and distinct properties in comparison to Nylon:

Glass-filled Polyamides are extremely popular for certain applications as they have unique properties that are unlike any other thermoplastic. Let’s take a look at these unique properties and their various advantages:

Glass-filled polyamides are known to have more advantages over their natives and while these composite blends have superior physical, chemical, and mechanical properties, they also have some disadvantages. You should note that every injection molding material has its limitations. It is thus imperative to understand the limitations and note how they can affect your project. Let’s take a look at these limitations:

The glass fibers in the glass-filled Nylon increase the abrasion during injection molding which increases the wear and tear on the molds and machines. This raises new challenges as it decreases the performance of the machines and molds. Depending upon the part, the lifetime of the mold and the machine could be reduced by 30 to 50%.

The surface finish of glass-filled polyamide plastic parts is rougher if the plastic parts were manufactured via standard Polyamides. The reason for this is that in glass-filled Nylons, the glass fibers are visible on the plastic parts and thus, it is not possible to achieve a shiny or smooth surface finish.

Glass-filled Nylons are resistant to deformation but they are brittle in nature. There is always a risk of the composite fracturing under high-stress conditions. You should note that it’s comparatively more brittle than standard nylon.

If light-weightedness is a priority in your plastic part, then you should avoid using glass-filled composites. The addition of glass fibers in the Nylon matrix adds to the weight making the material heavier. Glass-filled Polyamides can weigh 15% more than native nylon.

The glass fibers in the nylon matrix make the material more abrasive. This abrasiveness wears the tools faster than standard Nylon. You should also note that parts made with glass-filled glass-filled composites are also more abrasive. The increased abrasiveness wears adjoining mated parts faster.

Glass-filled Nylons are more expensive than their natives. These blends cost approximately 50-100% more due to the additives and the additional processing it takes to make glass-filled Nylon.

Nylon is hygroscopic in nature. It absorbs moisture and it is thus necessary to dry the material before processing it further for manufacturing. Glass-filled Nylon too absorbs moisture and must be dried accordingly. It can otherwise lead to structural or dimensional weaknesses.

Though both the variants, Nylon and its glass-filled variant undergo weld line deformations when subjected to stresses, weld lines in glass-filled Nylon parts are significantly weaker.

Glass-filled nylons can be processed through injection molding, printing, and machining. Glass-filled nylon is a versatile material that can be manufactured through various techniques. Let’s understand these techniques further in detail:

Injection molding is one of the most popular and widely used manufacturing techniques for producing high-quality glass-filled Nylon parts. Molten plastic is injected into a mold cavity under pressure which then rapidly cools the plastic. The solid plastic part is then removed and if required, post-processed. There are various grades of glass-reinforced nylon that can be used to manufacture high-quality plastic parts. The most popular ones are nylon 66, with a fiber reinforcement of 10 to 50%.

The machining process involves using various tool types such as mills, drills, or lathes to remove material from a blank in order to create high-quality precision parts that have great tolerance levels. Glass-filled nylon can also be machined but there are some challenges that need to be addressed. You should note that the glass fibers embedded in the nylon matrix increase abrasion. This causes the machining tools to wear out quickly. Thus, it is preferred to use ceramic or carbide tools over traditional steel tools. It is also recommended to slow the cutting speed as that can also help to keep the abrasion at bay.

3D printing is one of the most popular technologies used to manufacture glass-filled Nylon plastic parts. SLS is the most popular 3D printing technology for manufacturing glass-filled Nylon parts that are fast and functional.

In the selective laser sintering (SLS) process, layers of powdered material of glass-filled Nylon are melted and fused using a laser. As the layering continues, the part begins to form in the print bed. When printing with glass-filled Nylon, it is recommended to use hardened steel nozzles as they have superior abrasion resistance!

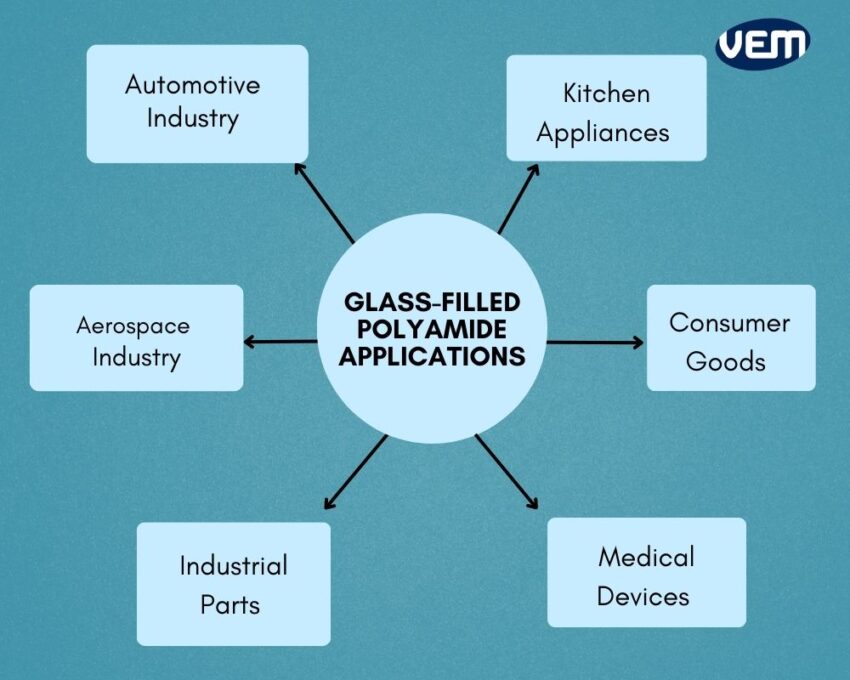

Glass-filled nylon has extremely advantageous properties such as high strength, rigidity, durability, electrical insulation, and excellent thermal resistance. These properties make it exceptionally popular to manufacture various product categories.

Its high strength and rigidity make it an ideal material for manufacturing plastic parts in the automotive industry. Glass-filled Nylon also has a good strength-to-weight ratio. Since weight reduction is key to improving vehicle efficiency, glass-filled Polyamides have managed to replace various heavy metal components in the automotive industry. This replacement has also enabled the industry to reduce costs effectively.

The current applications in the automotive industry include engine covers, air intake manifolds, speedometer gears, fuel rails, windshield wiper parts, wire housings, and connectors.

Glass-filled nylon is becoming increasingly popular in the medical device industry. The properties of Polyamide are well-understood and its reinforcement with glass fibers has boosted its strength, durability, and rigidity. It is implemented in the design of today’s medical devices! It’s frequently used to manufacture surgical instruments, medical tubing, and implants.

Reinforced Nylon is extremely popular in the aerospace industry due to its excellent strength-to-weight ratio. It is often applied to manufacture structural components such as control rods and wing flaps. Some other properties that make it an extremely note-worthy material are its toughness, tensile strength, and high-temperature resistance.

It is popularly used for demanding industrial applications due to its high tensile strength, and resistance to wear and tear. It is widely used in the industrial sector to manufacture gears, bearings, and other machine components.

Reinforced Nylons are used to manufacture an array of consumer goods such as kitchen appliances, power tools, and sporting equipment.

VEM-tooling is a premier provider of tooling and injection molding services. We have the skills and experience to carry out complex glass-filled nylon injection molding projects.

Glass-filled nylon injection molding is an ideal choice if strength, rigidity, and chemical resistance are a priority. You can contact us for more information about glass-filled nylon injection molding for your project, and we will get back to you right away

Glass-filled Polyamide is a synthetic thermoplastic that is made by mixing glass fibers with Polyamide. It is an engineering thermoplastic that is applied to manufacture various products in a wide array of industries.

Is Glass-filled Nylon a composite material?

Glass-filled Nylon has an off-white color. It also has a grainy surface finish.

Does Glass-filled Nylon also absorb water?