Material selection is a crucial aspect of manufacturing plastic parts. Especially when considering its application temperature, the right material selection is crucial. If high temperatures are part of the equation, then there is no way around heat resistant plastics.

A high temperature plastic material has high maximum continuous use temperatures, and elevated melting and transition temperatures. In addition to elevated temperature resistance, a high temperature material offers superior or unique polymer properties which are maintained even under sustained high temperature operating conditions. They are ideal for advanced applications. In this article, we discuss heat resistant plastics, its characteristics, applications and various types of heat resistant plastics in detail.

Plastics are classified as heat resistant plastics if they can withstand sustained operating temperatures or a continuous-use temperature of above 150°C / 302°F or for a short-term exposure of over 250°C / 482°F.

You should note that the heat resistance of plastics can be additionally improved through the inclusion of additives such as glass or carbon fibers. These additives not only increase thermal resistance of the resins but they also improve the overall stiffness, dimensional stability, and material strength.

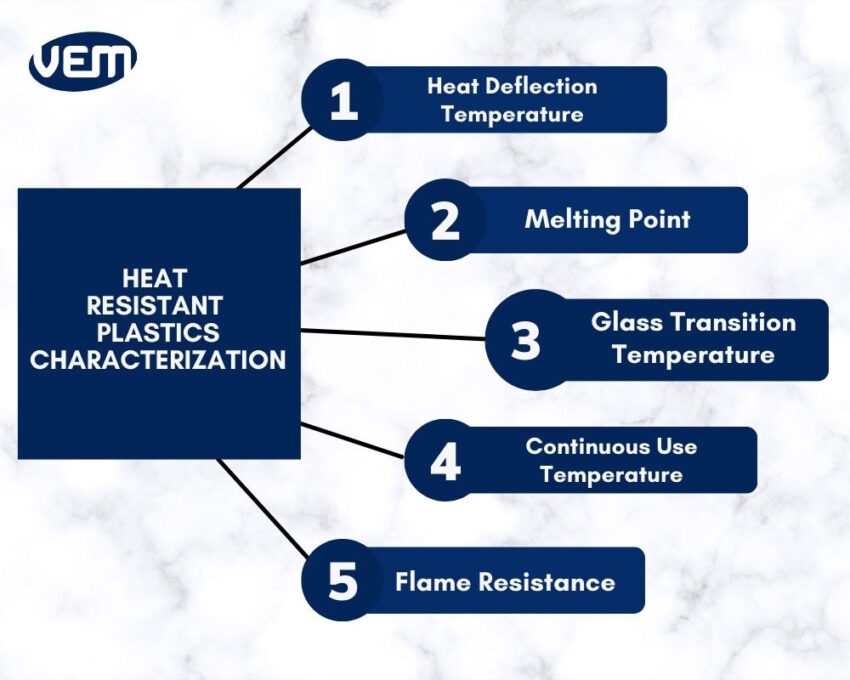

Heat resistant plastics have certain parameters that are applied to describe their thermal properties. Let’s understand some of the key methods of characterizing a plastic’s heat resistance:

HDT, abbreviated for heat deflection temperature, is the temperature at which the plastic deforms under a predefined load. It is also referred to as the heat deflection temperature under load, abbreviated as HDTUL. It measures how well a material maintains its stiffness under an applied load. You should note that HDT does not account for any long-term effects upon the material if the temperature is held for extended periods of time.

The melting point of a heat resistant plastic material is the temperature point at which the resin softens. You should note that semi-crystalline resins have a precise melting point, whereas the amorphous resins soften gradually as they heat.

The glass transition temperature, represented as Tg is the temperature point at which a material transitions from being ductile into a brittle material. If the heat resistant plastic material is an amorphous polymer, it refers to the material changing from a hard material to a soft and rubbery, or viscous material.

CUT, abbreviated for continuous use temperature is also referred to as continuous operating temperature. It refers to the maximum safe operating temperature of the heat resistant plastic for long-term use. The point at which the plastic can be continuously used without leading to significant degradation to its mechanical properties over the part’s design lifetime.

The flame resistance of a heat resistant plastic material is the measure of the plastic’s resistance to burning. Testers measure flame resistance through UL 94 tests and rate it on a scale. A heat resistant plastic material with the ratings of V-0, V-1, and V-2 are accepted for use in consumer products. You can read more about it here.

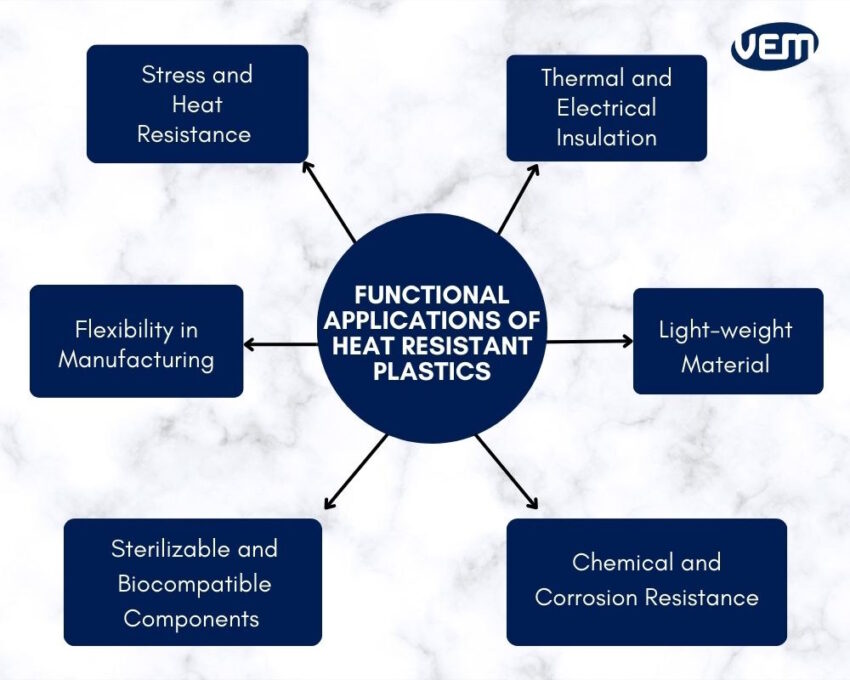

Heat resistant plastics demonstrate unique properties and are thus employed for various functions. They combine durability, light-weightedness, and resilience under extreme temperatures. They perform unique functions that conventional resins or metals aren’t able to perform. Let’s understand the various functional applications of those plastics.

High temperature plastics enable manufacturers to produce structural components that can withstand stress and heat. When a high temperature plastic material is incorporated, it provides mechanical strength and structural integrity under high temperatures.

For instance: Manufacturers commonly apply Polyamide with 30% Glass Fiber to manufacture automotive components such as engine covers and turbocharger brackets as they require strength, thermal stability, and chemical resistance. PEEK, abbreviated to Polyether Ether Ketone, are applied for manufacturing structural brackets and fasteners in aircraft due to its high strength and thermal endurance.

Plastics in general are lighter than metals and thus improve the overall efficiency of the part. It reduces weight while maintaining thermal and mechanical stability. This particular aspect makes heat-resistant plastic ideal for applications where light-weightedness is a priority, i.e., the automotive and aerospace industries.

For instance: Manufacturers apply PEEK and PPS to manufacture aerospace components due to their exceptional thermal resistance and mechanical strength. These aspects enable manufacturers to produce lighter structures that perform in extreme conditions.

Metals tend to corrode when exposed to a range of chemicals. Some plastics demonstrate better corrosion resistance than metals, which is why they are employed to manufacture parts that may be continually exposed to chemicals or corrosive environments.

For instance: Manufacturers use PPS i.e., Polyphenylene sulfide to produce valves, seals, and pump components as it can resist corrosive substances while operating at elevated temperatures.

Heat resistant plastics offer flexibility in manufacturing over metals, as they can be manufactured using high-volume production technologies such as injection molding. This enables manufacturers to lower the per-part cost as opposed to their CNC-milled metal counterparts.

They demonstrate properties of thermal and electrical insulation. These properties make them an apt material of choice for sensitive electronics. They ensure reliable insulation and prevent electrical failures under heat stress.

Manufacturers employ Polyetherimide in the electronics industry for its outstanding dimensional stability and electrical insulation properties at elevated temperatures. It’s specifically applied to manufacture electrical connectors, circuit board housings, and insulating components for power electronics. These components ensure safe and reliable electrical performance in devices ranging from computers to industrial control systems.

Producing sterilizable and biocompatible components for the medical device industry is important to any medical manufacturer. A high temperature resistant plastic material can withstand repeated sterilization cycles without losing mechanical or dimensional integrity.

For instance: Medical device manufacturers apply to manufacture autoclavable housings for diagnostic tools and surgical instrument handles as they frequently need to undergo high-temperature steam sterilization, i.e. autoclaving while maintaining biocompatibility and mechanical performance.

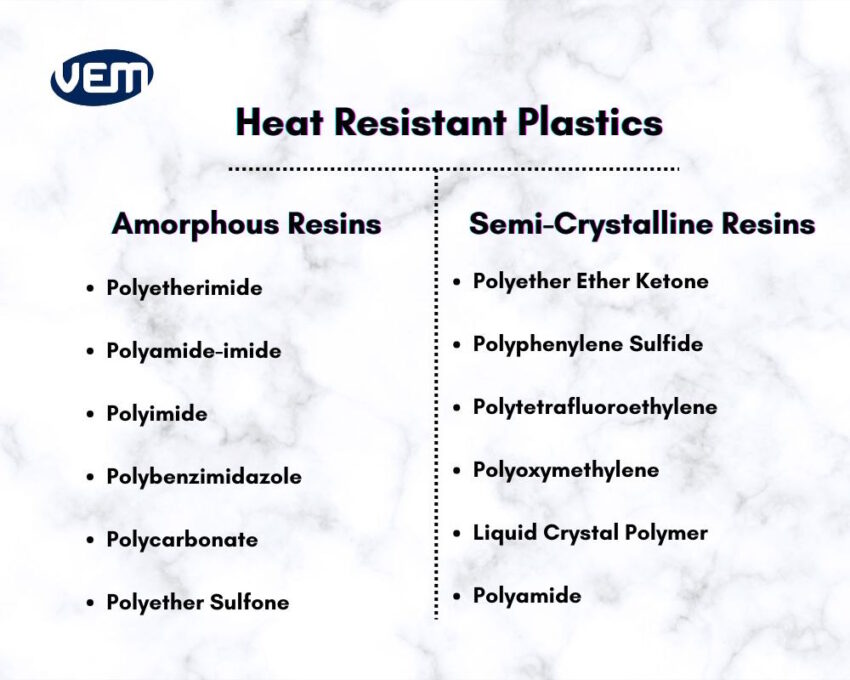

Just like most plastic materials, heat resistant plastics are broadly categorized as amorphous and semicrystalline. In this section, we discuss these two categories and various types of heat resistant plastics.

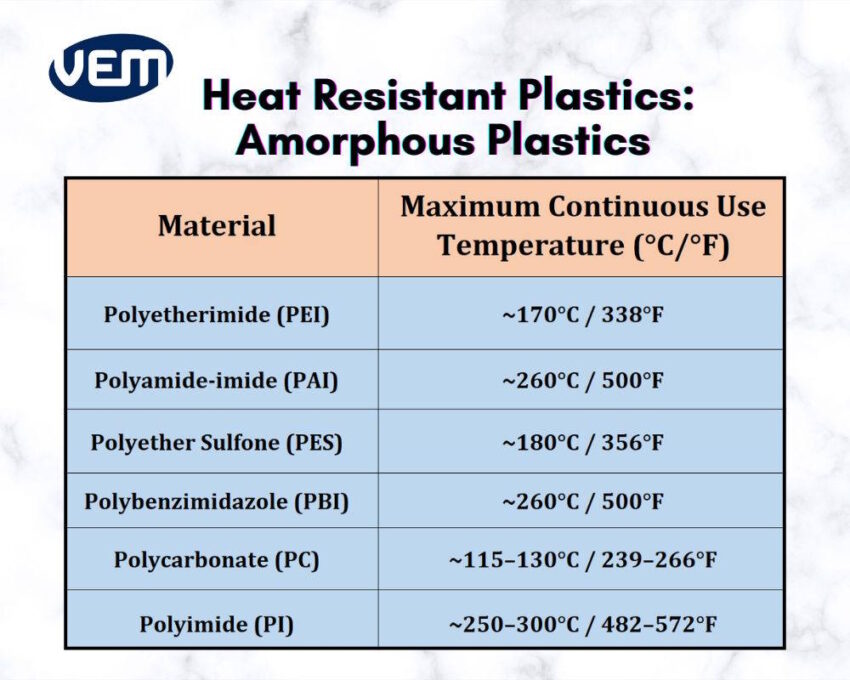

Amorphous heat resistant plastics don’t have a true melting point but gradually soften as the temperature increases.

Polyetherimide is popularly known by its trade name of Ultem. It’s an amorphous heat resistant plastic material that demonstrates exceptional thermal and mechanical properties. It has a maximum CUT of approximately 170°C / 338°F. It demonstrates better creep resistance than most thermoplastics, and has a high tensile and dielectric strength. It is widely used in the aviation industry, especially for cabin interior.

Polyamide-imide is an amorphous heat resistant plastic material that maintains its mechanical properties at elevated temperatures for extended periods. It demonstrates excellent mechanical strength, radiation, and corrosion resistance. It can withstand continuous use temperatures of up to 260°C / 500°F.

Polyimide is also a high temperature plastic material that demonstrates extreme thermal and chemical resistance, which is why it’s often employed for high performance applications. It demonstrates excellent mechanical and thermal stability at high temperatures and can withstand a continuous use temperature of 250–300°C / 482–572°F.

Polyether Sulfone is known for its excellent hydrolytic stability, high tensile strength, and stiffness. It also demonstrates good electrical insulation properties and flame resistance. PES can withstand a continuous temperature of approximately 180°C / 356°F.

Polybenzimidazole demonstrates the highest heat and wear resistance, strength, and mechanical stability. PBI doesn’t demonstrate a true melting point and can withstand continuous use temperatures of up to 260°C / 500°F.

Polycarbonate is typically employed for aesthetics, where high-quality appearance is a priority in parts. PC softens over a range of temperatures, and typically, has maximum continuous use temperature of 115°C to 130°C / 239°F to 266°F. You can read more about PC here.

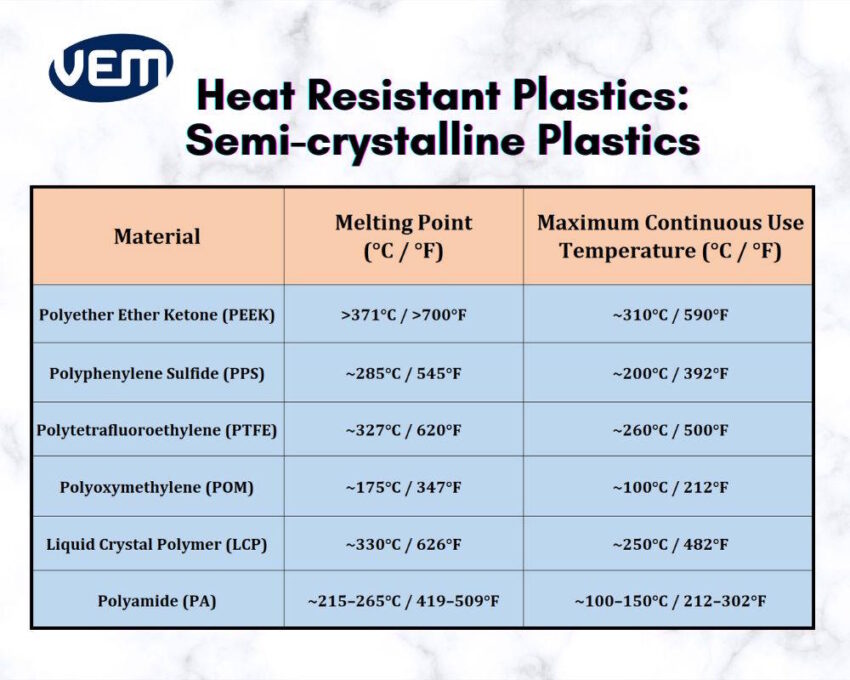

Semicrystalline plastics have a true melting point, and they transition sharply at a specific temperature point from solid to liquid phase. Let’s understand various types of semi-crystalline heat resistant plastics:

Polyether ether ketone, acts as a strong thermoplastic and adapts to extremely harsh environments. PEEK is an excellent heat resistant plastic material as it can withstand extremely high temperatures of upto 310°C / 590°F and has a melting point of above 371°C / 700°F. You can read more about PEEK here.

It demonstrates metal-like durability, high tensile and flexural strength. It’s resistant to chemicals, wear, fatigue, creep, and heat, but is susceptible to UV light and certain acids.

Polyphenylene sulfide demonstrates a good balance of mechanical, chemical, and thermal properties. PPS can withstand high continuous use temperatures of up to 200°C / 392°F and has a melting point of approximately 285°C / 545°F. It’s inherently flame-resistant but demonstrates poor dielectric strength.

Polytetrafluoroethylene is commonly known through its brand name Teflon. It’s a unique heat resistant plastic material as it demonstrates exceptional chemical resistance. It’s chemically inert and insoluble in most solvents. It can withstand continuous use temperatures up to around 260°C / 500°F and has a melting point of approximately 327°C / 620°F.

PTFE is a soft, heat-resistant, low-friction high temperature plastic material and demonstrates high flexural strength, and good electrical insulation.

Polyoxymethylene demonstrates excellent dimensional stability, chemical, and wear resistance. It provides good stiffness and demonstrates low friction. Comparatively, it has a lower melting point of around 175°C / 347°F, and it can withstand continuous use temperatures of up to 100°C / 212°F. You can read more about POM here.

has various advantages, but it isn’t ideal for every custom injection molding project. Let’s understand these limitations further:

LCP is a semi-crystalline thermoplastic known for its exceptional thermal stability and mechanical performance at elevated temperatures. It demonstrates outstanding chemical resistance, excellent dimensional stability, high strength and stiffness. It can withstand continuous use temperatures of up to around 250°C / 482°F and has a melting point of approximately 330°C / 626°F.

Polyamide is commonly known by its trade name, Nylon. It demonstrates excellent heat and abrasion resistance properties. It typically has a continuous use temperature of around 100°C – 150°C / 212°F – 302°F and has a melting point of approximately 215°C – 265°C / 419°F – 509°F. You can read more about Polyamide / Nylon here.

Heat resistant plastics offer unique advantages. They enable manufacturers to produce parts that can withstand extreme thermal conditions.

Selecting the right high temperature plastic material requires technical expertise. VEM Tooling has a vast experience of over 20 years in tool building and manufacturing plastic parts. Our experienced engineers can guide you with the correct material selection and help you understand which heat resistant plastic material is apt for your project.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.