Injection molding technology has evolved into one of the most versatile and dependable manufacturing processes that can be applied to an array of industries. Today, plastic injection molding technology has evolved such that there are various types of polymers and innovative processes to achieve increasingly tighter tolerances and repeatability. An innovation that has revolutionized the plastic injection molding industry to strides was the development of hot runner technology.

Hot runner systems were introduced in the 1960’s and since then, have continued to evolve rapidly. These systems enable manufacturers to reduce material waste, improve control, and increase productivity.

Hot runner technology optimizes molding processes to achieve superior melt control and processing performance, thereby yielding high-quality parts. While they do increase the initial mold cost, the enhancements in efficiency and production not only compensate for it but also make it more economical. The system is designed to create high-quality products with efficiency and accuracy.

Hot runner technology presents manufacturers with solutions to solve novice challenges of the industry and in this article, we discuss hot runner systems, their various types, applications, and design considerations in detail.

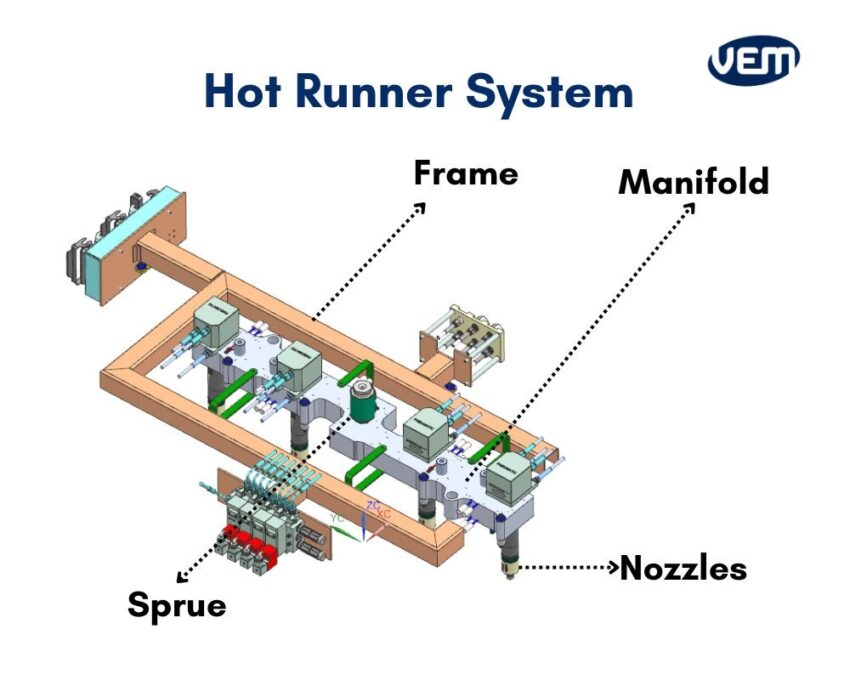

Hot runner systems are also referred to as runnerless molding or hot-manifold systems and are a set of heating devices that are installed in the mold for temperature control.

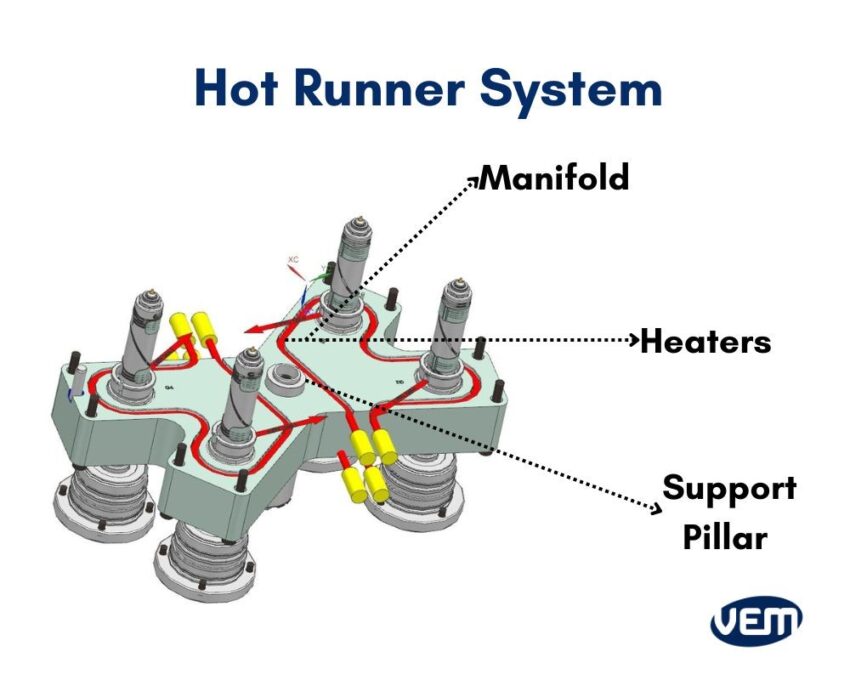

A hot runner system is an assembly of heated components that directly inject molten resin into the mold cavities. These systems incorporate a heated manifold to keep the resin in its molten state. It’s a complex control system that ensures a consistent melt distribution and flow. Heating of the runner systems can be achieved through coils, cartridge heaters, heating rods, heating pipes, and band heaters.

This particular system consists of a heated barrel, a manifold, and a set of nozzles. The molten resin is first, injected into the mold through the nozzles. The heat of the barrel keeps the plastic in a molten state and then, it further, flows into the mold cavity. The molten resin cools to harden in the mold cavity.

The heated plastic travels through internal channels that are referred to as hot runners and they deliver molten resin into multiple cavities. The hot runner molding process ensures that the runners are sufficiently hot so that the plastic can be in a molten state throughout the process. The purpose of a hot runner injection system is to keep the runner channel above the melting point of the plastic and maintain the flow rate of the plastics from the injection molding machine nozzle to the gate in a plastic injection mold.

Hot runner systems are particularly beneficial when part geometries are complex and challenging. It is also beneficial when the margin of error in the flow properties is expected to be extremely low. Furthermore, hot runner systems reduce plastic wastage during high-volume shoots.

A Hot runner system consists of two plates that are heated by a manifold system that further sends the melted resin to the nozzles, which then feed the cavities of the part. Various components assemble this system. Let’s understand these components further:

Cold runner systems are typically cheaper and more cost-effective when compared to hot runner systems making them a preferred choice for certain applications.

In contrast to hot runners, cold runners are an unheated channel that directs molten resin into a tool cavity after it leaves the nozzle. The primary difference between the two technologies is that hot runners are heated while cold runners are not.

You should note that hot runner systems are more complex than cold runner systems as they require additional components such as manifold systems, heated nozzles, and temperature controllers but they still have various advantages over cold runner systems.

Since cold runners are unheated, the channels need to be larger as more plastic can be shot during each cycle.

A hot runner system can further, be highly efficient, reduce plastic wastage and demonstrate an increased design flexibility to manufacture intricate, complex parts.

The decision of whether you must use a hot or cold runner system must be considered case by case after thoroughly evaluating each parameter. You should however note that, if the production volume is medium to large, then hot runner molds can be advantageous as the extra cost is easily recovered through faster cycle times, high-quality parts, and raw material savings.

Hot runner systems are versatile, effective, and efficient and they can thus be applied to an array of applications of various industries. Let’s understand some of the applications further:

Hot runner systems minimize wastage during mass production thus, they are popularly applied to manufacture consumer goods at a large scale. Some examples include electronic components, household appliances, and toys.

In the industrial sector, this process is applied for manufacturing critical components of the industrial sector such as connectors, valves, gears, and enclosures. The flow of the molten plastic can be controlled precisely which further demonstrates excellent dimensional accuracy and consistent quality.

Hot runner systems manufacture high-quality, dimensionally accurate parts which is why this process is often used to create parts for the automotive sector.

Hot runner systems help to efficiently manufacture a variety of plastic packaging products such as bottle caps, closures, containers, and lids.

The complex and intricate design of medical devices can be manufactured precisely and efficiently via hot runner systems. Some examples include syringes, inhalers, and surgical instruments.

Hot runner systems can be classified based on their structure and their heating mechanisms. Let’s understand these types further:

An insulated runner system is ideal for heat-sensitive thermoplastic polymers. This type of hot runner system requires an extremely thick runner channel so that the resin can stay molten during continuous cycling. These types of molds have extra-large passages that create an open molten flow path.

This system makes use of extra-large-sized passages to maintain the heat insulation of the molten resin. Insulated runners have relatively simpler designs and they are more cost-effective than other hot runner molding system types however; there can be issues with uneven filling.

Internally Heated System: These types of systems are heated by a probe and torpedo located in the passages. Internally heated systems have better flow control as they make use of torpedo cartridge heaters with thermocouples which are placed inside the runners. Since the resin gets heated from the inside, it’s a more efficient process than externally heated hot runner systems.

This system requires higher molding pressures, and shouldn’t be used for thermally sensitive plastics. You should note that internally heated systems have many areas, where the resin can stick to the surface and degrade.

Externally Heated System: These types of systems are heated by a cartridge-heated manifold with interior flow passages. Externally heated hot runner systems make use of several temperature control systems to control the melt temperature in the manifold and surrounding the runner channels. Some examples of temperature control systems that are commonly used in external heated systems are cartridge heaters, heat pipes, coil heaters, and torpedo heaters.

Externally heated systems work better than other systems for color changes as colors in the runner don’t freeze. Additionally, externally heated systems are devoid of areas where the resin can stick to.

This type of hot runner system incorporates a valve that functions through a needle’s mechanical movement to control the nozzle opening. The valve gate system employs mechanical and hydraulic pressure to control the needle. It enables closing the hot nozzle completely when the part is being condensed during the holding time.

The valve gate hot runner system ensures smooth cavity filling and balanced melt flow. It also helps to eliminate weld marks and seam lines in the parts.

This particular system relies on a hot tip that is located at the nozzle’s front end and also has a cooling mechanism. It thus enables precise adjustment and maintains control of the molding temperature at the gate. The critical factors in this process are the material and shape of the nozzle’s hot tip.

Hot-tip Hot gates are ideal for manufacturing parts that have smaller dimensions, with gate diameters ranging from 0.5 mm / 0.019 inches to 2.0 mm / 0.07 inches. The size of the gate is dependent upon various factors such as the weight of the part, wall thickness, and material quality.

This system injects molten resin into a mold through a sprue, thus, ensuring a low pressure at the gate and the advantage of maintaining a low shear rate. This leads to minimal residual stress and deformation.

The sprue gate is larger than the hot tip thus, allowing for larger gates. This type of system is usually designed and considered for medium-sized or heavy injection molding projects.

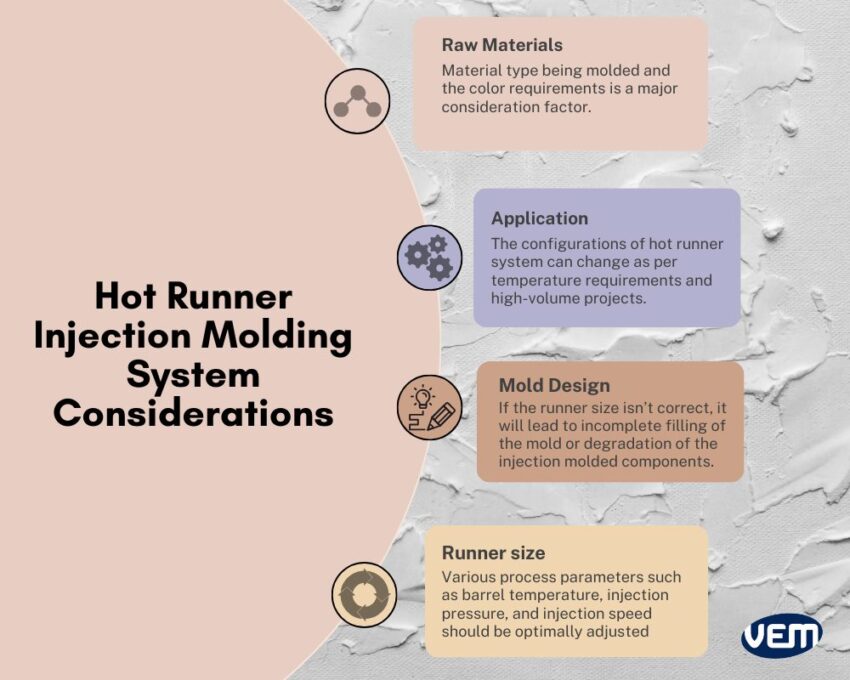

Several factors must be considered when choosing a hot runner system for your project. Let’s understand these factors further:

Each hot runner system has unique properties that fit certain requirements of a particular project. It is crucial to examine the design process to ensure apt operations.

The size of the runner has a significant impact on the performance of the hot runner system. If the size of the runner isn’t correct, it will lead to incomplete filling of the mold or degradation of the plastic injection molded components.

To determine the correct runner size, you need to consider various factors such as pressure drop, residence time, temperature, shear rate, and frequency.

The configurations of hot runner systems depend significantly upon the application! You should note that configurations can also change as per temperature requirements and high-volume projects.

The next factor that should be considered is the material type being molded and the color requirements.

For instance: If the material being used is a glass-reinforced plastic, then the gate inserts must provide considerable wear resistance, and if the resins degrade easily, then an external heat system runner system can be incorporated to avoid dead corners.

Manufacturers prefer hot runner systems due to their various advantages. Let’s understand some of the benefits of hot runner systems:

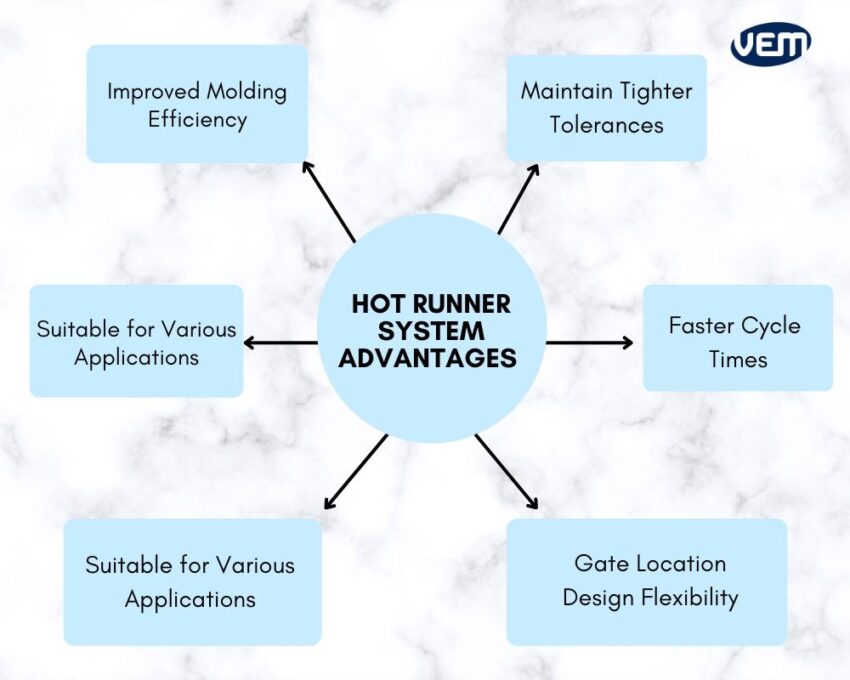

It is possible to maintain a more balanced melt flow with hot runner systems thus, allowing to pack cavities completely. Thus, enabling molders to meet tighter tolerances.

Hot runner systems demonstrate an excellent capacity to deliver uniform melt viscosity. They also deliver better injection pressure control, thereby, reducing the melt shot capacity thus, leading to improved molding efficiency.

In addition, the parts are produced quickly with better quality control governed at each step of the injection molding process.

Injection molding itself is an extremely efficient and fast process, and it is even faster with hot runner systems. The hot runner system keeps the thermoplastic molten which prevents various types of defects in the finished part. Thus, it creates a more cost-effective manufacturing process.

Hot runner systems can reduce the cycle time by 10% to 30%. Since the shot sizes of the hot runner system are reduced, productivity increases and the cycle times are thus, relatively faster. In addition, since there isn’t a restriction on the sprue system’s cooling time, the parts can be ejected as they are formed and cured. Thus, the cycle times are faster.

Hot runner systems enable manufacturers to reduce plastic waste as it prevents cold slugging thus, plastic buildup in the runner or gates can be prevented thereby, saving on raw plastic. This is especially helpful when premium or expensive plastic is a requirement for the project. In addition, hot runner systems are extremely efficient which optimizes the process to reduce waste.

Hot runner systems enable design manufacturers to place gates at various points and ideal locations on the part thereby enabling optimization for cavity orientation, cooling, and simplified mold structures.

This system enables the injection molding process to be more efficient. Hot runner systems help manufacturers deliver high-quality products that require high precision and durability and are thus, suitable for an array of applications.

Hot runner systems eliminate secondary processes which enable manufacturers to introduce automation in production. If the part is finished in the hot runner mold, then there is no requirement to recycle cold sprue or trim the gate.

Hot runner systems have various advantages but they also present the manufacturers with some challenges. Let’s understand these challenges further:

Hot runner systems reduce waste and increase productivity but they are also more expensive due to their more complex mold features. In addition, they typically have expensive maintenance requirements.

Hot runner systems incorporate manufacturing equipment that are typically more complex and require to be operated aptly. You should note that more training is required to operate the machinery correctly which can lead to higher labor costs for operators that have specialized experience.

Thermally sensitive materials cannot be processed via hot runner systems due to the additional heat exposure.

Color changes are not possible easily via hot runner systems. To change colors, a multi-step purge needs to be carried out of the resin in the mold which leads to excessive amounts of scrap.

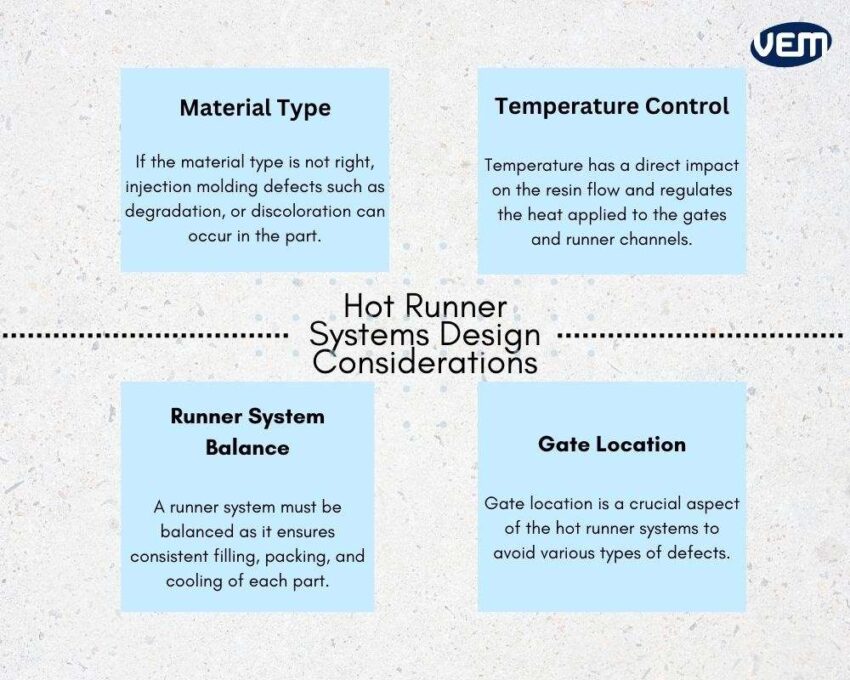

Gate location is a crucial aspect of the hot runner systems. This is the location, through which the molten resin enters the cavity. The gate should ideally be located near the thickest area of the part to avoid injection molding defects such as sink marks and plastic warping from arising.

You should note that gates shouldn’t be located near functional features such as edges, corners, and ribs to avoid the formation of flash, or knit lines. In addition, the gates should be aligned with the primary flow direction of the resin. This alignment reduces shear stress and the formation of weld lines.

The next factor that must be considered is the design of the runner balance. This factor equalizes the distribution of molten resin across multiple cavities.

A runner system must be balanced as it ensures consistent filling, packing, and cooling of each part. The runner system can be balanced by designing the channels such that they are of equal length and diameter. The size and shape of the runner must be adjusted after considering the viscosity, thermal expansion, and pressure drop of the plastic.

Temperature control is a crucial component that must be considered while designing mold and part geometry for hot runner system designs as it directly regulates the heat that is applied to the gates and runner channels.

Temperature control has a direct impact on the flow and viscosity of the molten resin and thus, further impacts the moldability and part quality. You can avoid temperature-related defects, such as burning, or brittleness by maintaining a uniform and optimal temperature throughout the hot runner system.

The temperature is highly dependent upon various factors such as the material type, part geometry, design of the mold, environmental conditions, and apt heating and cooling systems to deliver heat accurately and efficiently.

The material type has a direct impact on the performance of the hot runner system and the molded parts. If the material type is not right, injection molding defects such as degradation, or discoloration can occur in the part.

When selecting material type, various parameters such as thermal stability, melt flow index, colorant content, and moisture sensitivity are considered to ensure that the correct material is selected.

Hot runner technology optimizes manufacturing processes to achieve superior processing performance and high-quality parts.

If you are unsure whether your project is suited for hot runner injection molding, don’t hesitate to contact us. Injection molding and tooling services have been our core competency for decades.

At VEM-Tooling, we have an expert team of engineers who can help you choose the right solution for your project!