In the manufacturing industry, material selection is a crucial aspect for producing high-quality parts. Among the various rheological measurements, the melt flow index, or the melt flow rate is an essential metric that enables manufacturers to understand the polymers’ flow characteristics. Manufacturers typically employ it with other rheological parameters to make informed material and processing decisions. In this article, we discuss melt flow rate, how it influences resin selection, and its significance for polymer processing in detail.

MFR, abbreviated for Melt Flow Rate, is an important parameter and is included in technical data sheets and certificates of analysis. It measures polymer viscosity and flow capacity. Melt flow rate is often interchangeably used for MFI, abbreviated for Melt Flow Index, and it represents the same parameters. The polymer flows through a defined capillary under controlled conditions for 10 minutes, which defines its MFR and MFI.

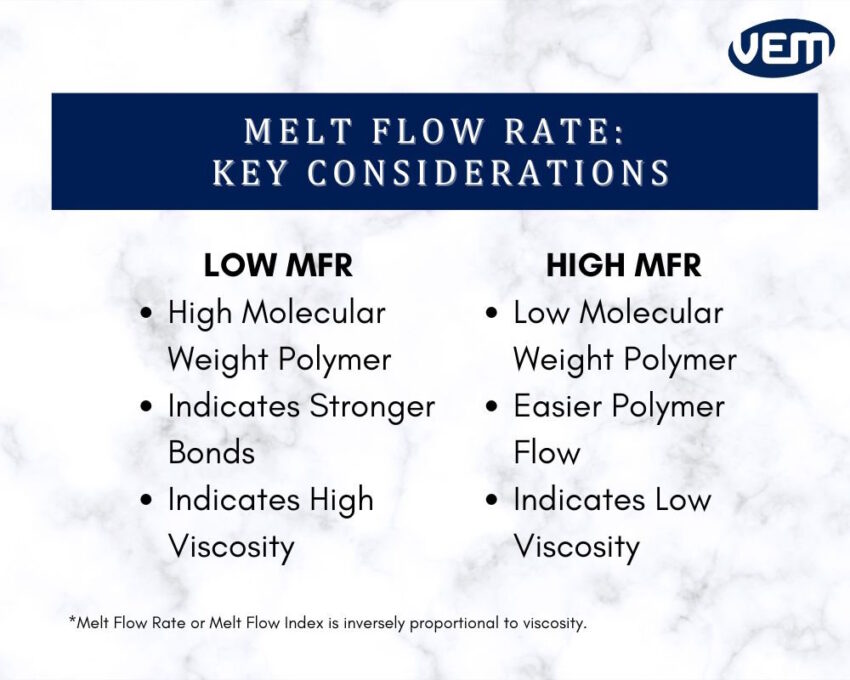

MFR or MFI is expressed as g/10mins, denoted for grams per 10 minutes, and is inversely proportional to viscosity. Melt Flow Rate or Melt Flow Index increases as viscosity decreases. The following image indicates the key considerations of the melt flow rate:

While melt flow rate is an extremely beneficial tool, it also has certain limitations. It may not account for complex flow behaviors as it represents a single point at low shear rates. In addition, it’s not a direct measurement of viscosity or molecular weight. The melt flow index must be used along with other rheological measurements for a better understanding.

Consistency in melt flow index among polymer batches is crucial for process stability. If the melt flow rate or melt index is inconsistent among the batches, it can lead to cost issues and negatively impact the productivity and quality of plastic processing.

Manufacturers should maintain an optimal melt flow rate. If the MFR is high, it can lead to injection molding defects such as flashing, whereas if it’s low, it can lead to incomplete part filling, thus increasing the reject rate. Let’s understand 2 key aspects:

If the melt flow index is low, then the polymer molecular weight is high. This indicates better mechanical properties, such as strength and toughness.

Polymer viscosity is inversely proportional to the melt flow rate. The polymers that have a high MFI indicate a low viscosity. This property makes them easier to flow, which further makes them easier to process.

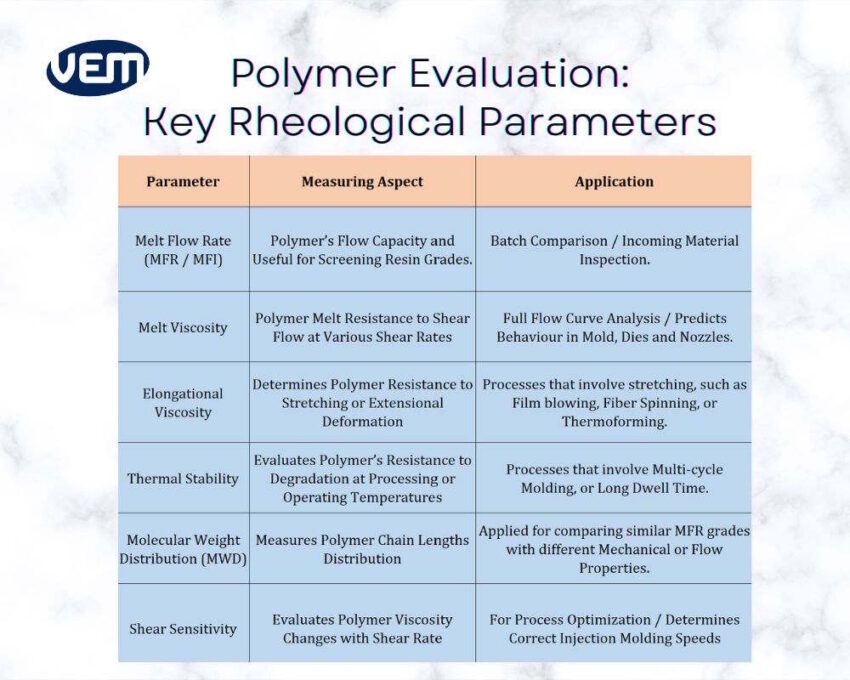

MFR is a helpful indicator, but it needs to be considered in conjunction with various parameters, such as melt viscosity, elongational flow behavior, thermal stability, viscoelasticity, molecular weight distribution, and shear sensitivity. The below diagram indicates some of the key rheological parameters in polymer evaluation:

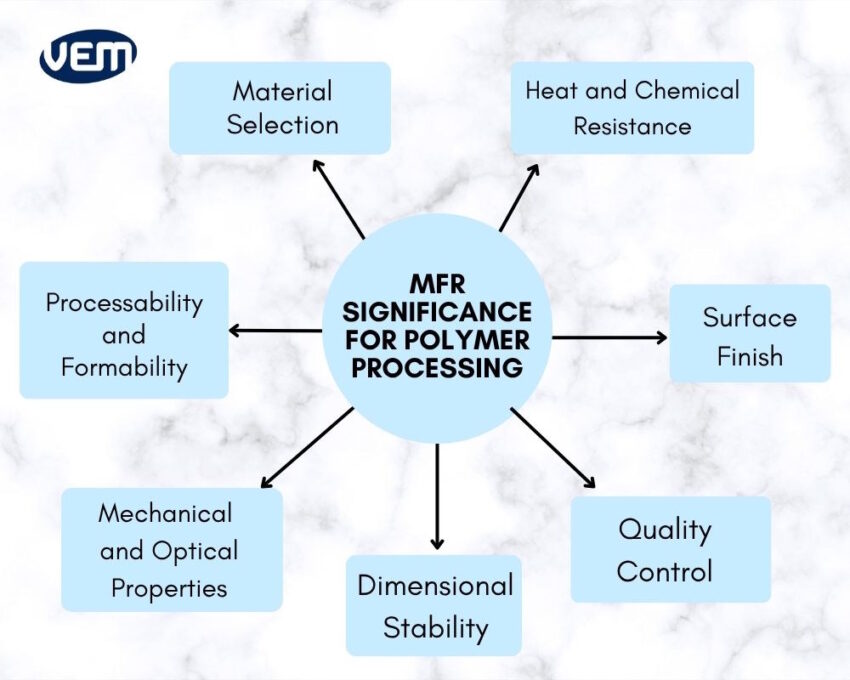

Melt flow rate indicates the processability of a polymer. It helps manufacturers to understand whether the polymer can be molded or extruded.

A material with a high melt index flows easily, which enables better filling of the molds. However, materials with a low melt index are more viscous, which leads to incomplete filling or flow issues.

MFR also indicates which material is apt for their application. It guides manufacturers to select the correct polymer for specific applications and processes.

MFI helps maintain the quality of the polymer and ensure consistency in polymer production, thereby aiding in maintaining product quality.

If the melt flow index is low, it indicates high molecular weight, which further means that the mechanical properties, such as strength and impact resistance, are better. On the other hand, if the melt flow index is high, the mechanical strength may be reduced, but there is an improvement in the processability.

Low MFI polymers exhibit better heat and chemical resistance than high MFI Polymers. Polymers with a high melt flow index are more prone to deformation at lower temperatures.

The melt flow rate has a significant impact on the dimensional stability of the finished part. If the melt flow index is high, then the polymer may shrink or warp during cooling, whereas lower MFI materials maintain their shape better.

The next impact is upon the surface finish of the part. A polymer with a high melt flow index produces smoother surfaces.

A low MFI material is better-suited for transparent plastics, as it provides good clarity.

Melt flow rate indicates the behaviour of plastics in real-world applications. It is one of the factors that determines whether the polymer can fill complex geometry or resist deformation under load. Let’s understand how MFR is applied in some of the industries:

Precision and sterility are paramount in the medical industry. A high MFR Polymer of 20–30 g/10 min is typically applied for manufacturing various medical device components such as syringes, IV connectors, and inhaler parts. Polymers such as Polypropylene and Polycarbonate flow well and rapidly into complex tool geometries.

In the automotive industry, achieving dimensional stability and impact resistance is most important. Polymers such as ABS, Polypropylene, and Polyamide 6 have a low to medium MFR of 5–12 g/10 min, which enables adequate flow in large molds. It also balances impact resistance and heat stability. A low MFR also helps to prevent sink marks and warpage in thick parts.

Most consumer electronics, such as TV frames, mobile phone and laptop housings, combine precision with aesthetics. The priority here is that the material fills the thin walls while being stiff and scratch-resistant. For such industrial applications, a medium melt flow rate of 8–15 g/10 min is commonly considered and applied. It ensures mechanical resilience and excellent surface gloss.

Pipe and profile extrusion is a type of manufacturing process that creates a continuous part and thus requires uniform flow and strength. For e.g. HDPE and PVC pipes. In such cases, a low MFR of 0.3–1.5 g/10 min is preferred as it ensures consistent wall thickness, an excellent tensile strength, and creep resistance. You should note that materials with a high MFR would flow easily, which can lead to irregular wall formation.

Blow molded containers, such as fuel tanks and detergent bottles, require a controlled flow for hollow parts. It needs a low to moderate MFR of 0.3–1.0 g/10 min to maintain parison stability and avoid sagging. You should note that such a polymer forms stronger parisons that can be inflated evenly.

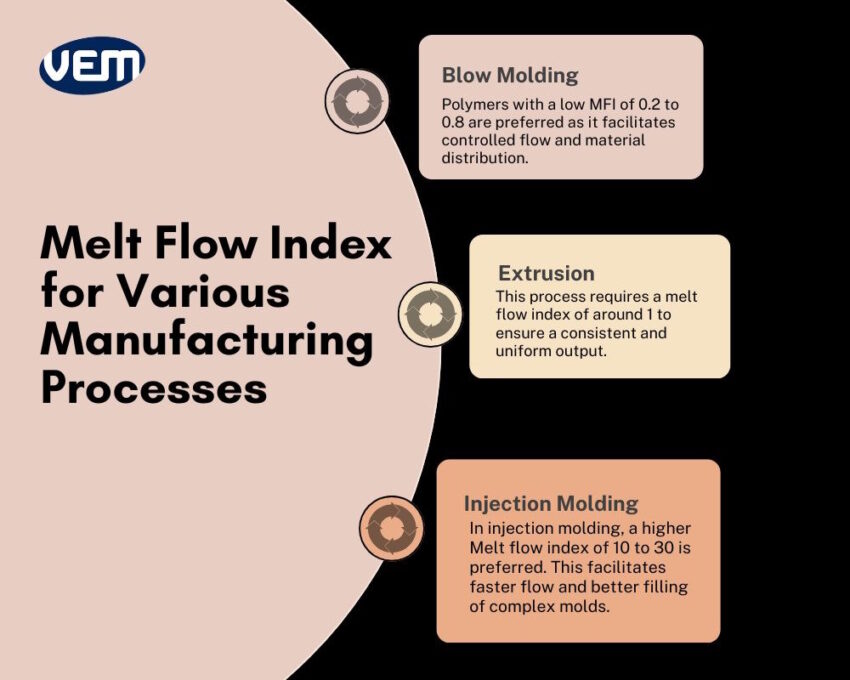

The melt flow index is specific for various manufacturing processes. In order to achieve optimal results, specific ranges of melt flow rate are employed. Let’s understand these further:

If the manufacturing process is blow molding, then polymers with a low MFI of 0.2 to 0.8 are required. This facilitates controlled flow and material distribution.

The extrusion manufacturing process requires a melt flow index of around 1 to ensure a consistent and uniform output.

In injection molding, a higher melt flow index of 10 to 30 is preferred. This facilitates faster flow and better filling of complex molds.

To determine the melt flow rate, operators measure the quantity of polymer that flows through an orifice within 10 minutes. The process of the melt flow rate involves the following steps:

Manufacturers measure MFR using a melt flow indexer or extrusion plastometer. You can determine it through either of two standard tests:

The above two standards are common international standards that are incorporated globally for MFI testing. You should study the relevant standard carefully to ensure you conduct the test in full compliance. Both the standards, ASTM D1238 and ISO 1133 define the load, temperature, and die dimensions for measuring MFR or MFI. These parameters indicate the actual conditions of polymer processing.

Quality management systems such as ISO 9001 and IATF 16949 include melt flow index testing as a key element. Manufacturers integrate it into the QMS in three main stages:

Manufacturers include melt flow rate testing in their incoming material checks. It ensures that each polymer batch meets the required specifications of the supplier before use.

Melt flow rate indicates whether the viscosity of the resin will be stable or not during production processes. Thus, the melt flow rate prevents variation in molded part performance.

Manufacturers record the melt flow rate in the Certificate of Analysis (CoA). Auditors use it as a traceable quality parameter.

The varying lengths of polymer chains determine their flow characteristics. You should note that they have a huge impact upon the melt flow rate. For instance, HDPE polymer consists of fewer branches, which leads to high flow rates but weaker mechanical properties.

Moisture easily affects the melt flow rate. If the resin or filler, i.e. the glass or carbon fiber absorbs water, then it affects the melt index.

Operator technique differences can change the melt flow rate. Therefore, the same operator should evaluate the melt index under identical conditions to ensure consistency.

Melt flow rate is an essential parameter for plastic processing. It enables manufacturers to select the most apt material for their processes and achieve the required performance and aesthetic characteristics.

For over 20 years, VEM Tooling has built tools and delivered manufacturing solutions. At VEM-Tooling, we have experienced engineering and design experts that can help you understand melt index and other material selection parameters for your process.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.