Custom injection molding is a mass manufacturing technology used to produce high-quality plastic parts. It’s a versatile manufacturing process where as single-cavity molds are typically used for lower volume runs. Multiple cavities especially come in handy when the parts are relatively small and needed in large quantities.

It involves multi cavity tooling that is built to include numerous identical cavities within a single mold base. It demonstrates a strategic advantage of enhancing production efficiency, ensuring batch-to-batch consistency, and driving cost-effectiveness for medium- to high-volume production runs. In this article, we discuss the technicalities, advantages, and limitations of those molds in detail.

Injection molding cavities refer to the number of parts that are formed in a single injection molding process. The number of cavities is directly proportional to the quantity of parts manufactured in each cycle. If there are more cavities, then more parts can be manufactured per cycle. So it can be said that multi cavity injection molding increases the production capacity by the amount of cavities.

A multi cavity mold is a type of mold that has at least two cavities. All the cavities are in even-numbered pairs and are identical. The number of cavities in the multi cavity mold is largely dependent upon the size of the part and tooling. The image above is a mold that produces spoons for the food industry. It is a 32-cavity mold and therefore molds 32 spoons in one cycle.

The amount of cavities can as high as 144 cavities. However, this is already on the very high end and will be quite difficult to make and maintain. The number of cavities are usually related to the expected production volume.

Typical layouts are 2, 4, 6, 8, 12, 16, 32, 64, etc. cavities.

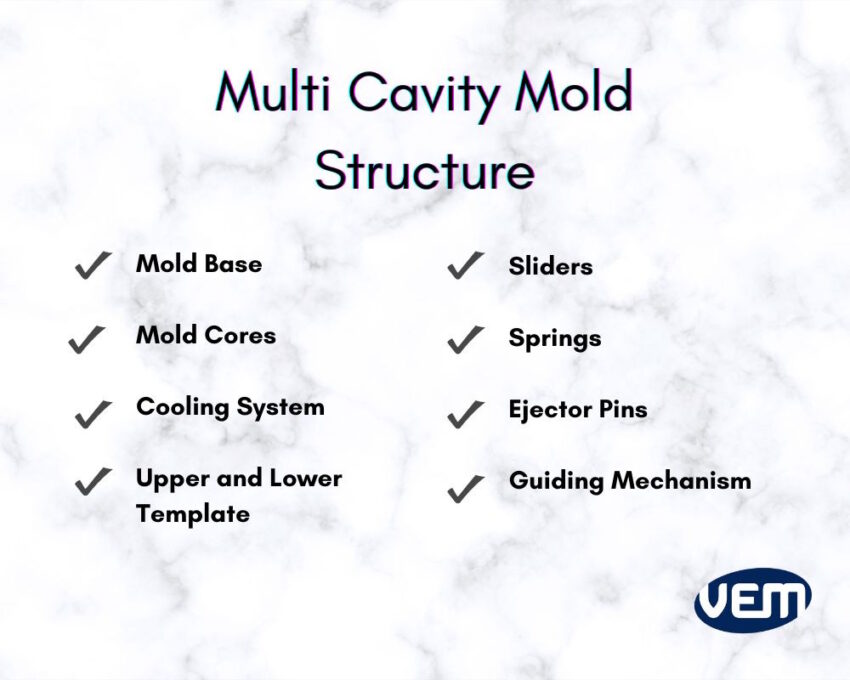

A multi cavity mold is very similar to a regular one cavity mold. However, due to the increased number of cores, the runner system is more complicated and often need more complex structures.

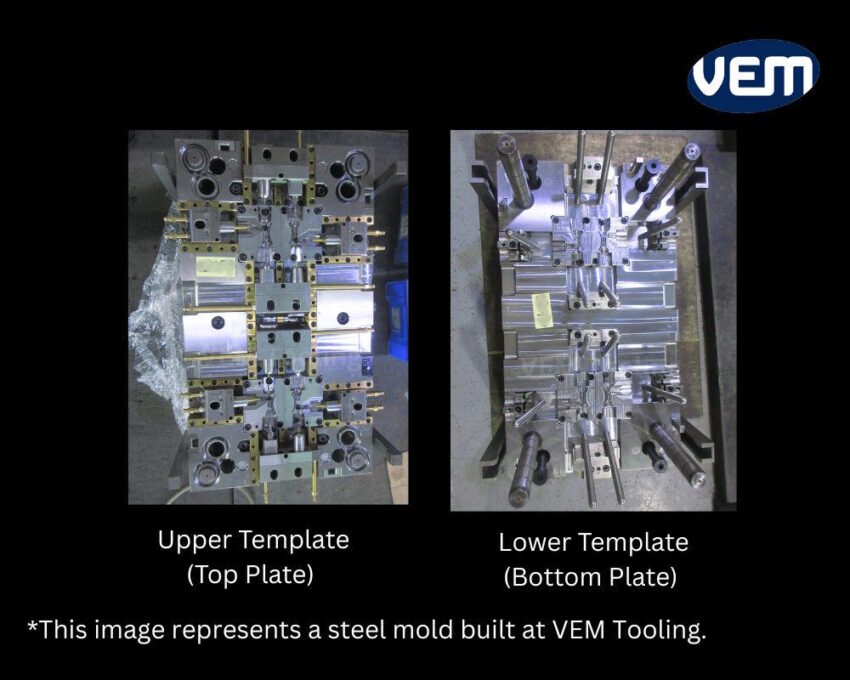

The upper and lower template of a multi cavity mold are referred to as clamping plates and are the outermost plates of the mold. They provide structural support to the mold and secure the mold components.

Sliders, just like in every mold, move laterally to release the molded part from the side features, and they then return to position before the next cycle. They are applied when the part cannot be released through a straight pull and are used to create undercuts or complex geometries.

The mold base provides a strong mold frame that holds all the components together. For multiple cavities, the moldbase wall is usually thicker, hence, more stability.

Mold cores are the most important structure, as they form the internal features of the part. They are positioned within the mold cavities. Mold cores are mounted on the moving side of the mold base (B-side).

Guiding mechanisms ensure that the alignment is accurate between the upper and lower halves of the mold. They are examples such as pins and bushings and they are especially critical in a multi cavity mold, as they prevent any type of misalignment.

Ejector pins push the solidified part out of the cavity once the molding is complete. They are placed in a multi cavity mold for uniform force distribution, and retract after each ejection.

Springs are incorporated with ejector systems or sliders. They apply return force and help to reset moving elements such as ejector plates or sliders to their original position after the ejection.

The cooling system circulates cooling fluids through channels in a multi cavity mold. They generate efficient and balanced cooling which further maintains uniform part dimensions and minimizes cycle time by accelerating solidification of the molten resin into the plastic part.

Part design analysis is an elemental step in designing a multi cavity mold. At this stage, the part design geometry is assessed to determine potential design challenges.

The next consideration factor is the mold material. It should be suitable for high-volume production runs and should be able to resist when subjected to high pressures and temperatures. For e.g., Hardened steel or high-grade aluminum.

In any mold, the base supports the entire structure of the mold. It should be wear and corrosion-resistant.

The next step is to optimize cavity layout in the multi cavity mold for efficient material flow. The cavities should be arranged symmetrically for balance and such that injection molding defects are prevented.

The runner system enables the molten resin flow to the cavities and ensures that the cavities are uniformly filled.

It is essential to implement correct cooling channels and venting systems. They help to maintain an efficient cycle time.

Venting systems enable trapped air to escape during the custom injection molding process, whereas cooling channels enable even distribution of temperature across all cavities.

The role of an ejection system in a multi cavity mold is to ensure that the part removal is smooth. It shouldn’t cause any deformation to the part.

A multi cavity mold is applied to manufacture an array of products for various industries. They are particularly applied, when cost-efficiency are crucial parameters for high-volume production runs. Let’s understand some of the key applications:

Consumer goods are everyday items that typically need to be manufactured in large quantities consistently. A multi cavity mold is extensively applied to manufacture consumer goods items such as plastic bottles, food containers, bottle caps, toothbrush handles, cosmetic packaging, kitchenware components, etc. The fast cycle times and high repeatability offered by multi-cavity molding help meet market demands.

Medical components require the utmost precision and are often required in large volumes, especially consumables. A multi cavity mold, enables manufacturers to meet such strict regulatory standards in cleanroom environments. Most common medical consumables that we know from everyday life, such as syringe barrels, test tubes, diagnostic casings, etc. are produced from multiple cavities.

Automotive manufacturers extensively apply multi-cavities tooling for manufacturing small, repetitive parts that require tight dimensional tolerances. Some common examples are clips, fasteners, cable guides, dashboard clips, valve caps, sensor housings, etc.

For larger parts, regular one cavity molds are used.

In the electrical and electronics industry most parts are rather small and needed in large quantities. Seeing multi cavity molds for components such as connectors, switch housings, plugs, etc. is pretty common.

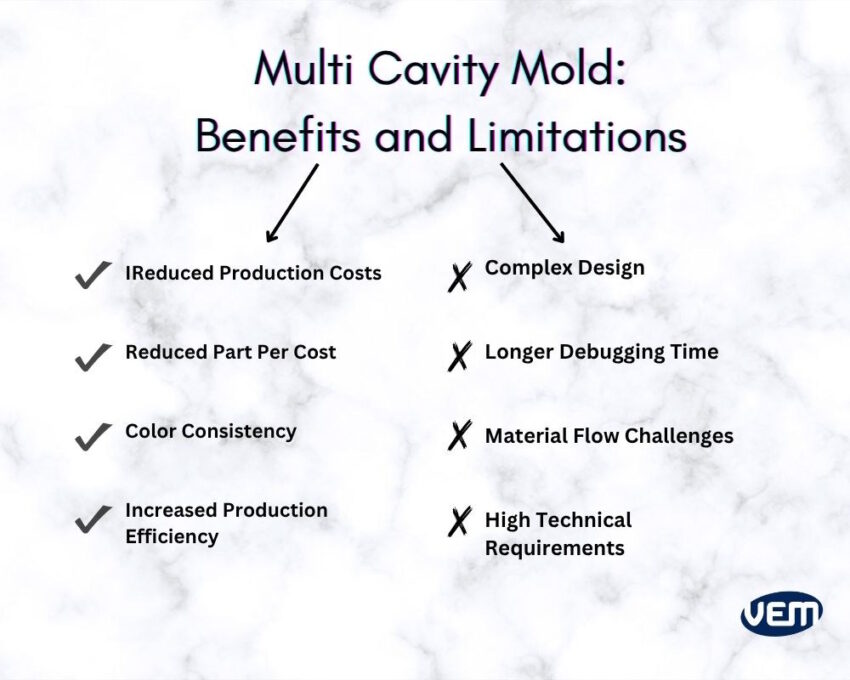

Having more than one cavity has several advantages. Let’s understand these advantageous aspects further:

A multi cavity mold aims to increase the production efficiency. It is capable of increasing the production capacity of custom injection molded parts based on the number of cavities.

If the production volume is large, a multi cavity mold reduces the production costs significantly thus, leading to substantial cost savings for high-volume production runs.

You should note that the initial cost of the mold may be higher due to its complexity, but the overall cost per part is much lower since more molds can be filled simultaneously.

Every manufacturer needs to make the cost-benefit calculcation on how many cavities are the most economic for the estimated part volume.

Colorants are added to the resin through various measurements, and while consistency is ensured to a great extent, there is always a possibility that perfect consistency across cycles may be altered. Having several cavities running in one injection machine enables better consistency of the plastic parts.

Having similar molds on various injection machines makes it harder to keep the color consistency, due to many small factors that can influence it.

A multi cavity mold has various advantages, but it isn’t ideal for every custom injection molding project. Let’s understand these limitations further:

Due to the increased number of cavities, the runner system becomes more complex and increases the difficulty of the entire mold design. This adds to the mold’s manufacturing cost thus, making them unsuitable for low-volume production runs.

A multi cavity mold takes longer to debug especially, if the multiple cavities are not perfectly balanced. It also requires more time to adjust and test to ensure that all the products meet the expected quality standards.

This also counts in the higher costs of it.

A Multi cavity mold has high technical requirements. The required expertise for design, manufacturing and simulation software to predict and solve potential issues is most important.

There are material flow challenges with a multi cavity mold. The material flows in various directions in a multi cavity mold. It is thus necessary to outline the parameters of the material flow.

We have built thousands of multi-cavity molds and are confident to built up to 64-cavities.

If you are unsure about the amount of cavities that you need, don’t hesitate and talk to an expert.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.