Today, injection molding is an integral segment of the manufacturing industry for creating plastic parts. It is used to create parts from an array of industries such as medical equipment, automotive interior parts, electronic housings, and plastic toys.

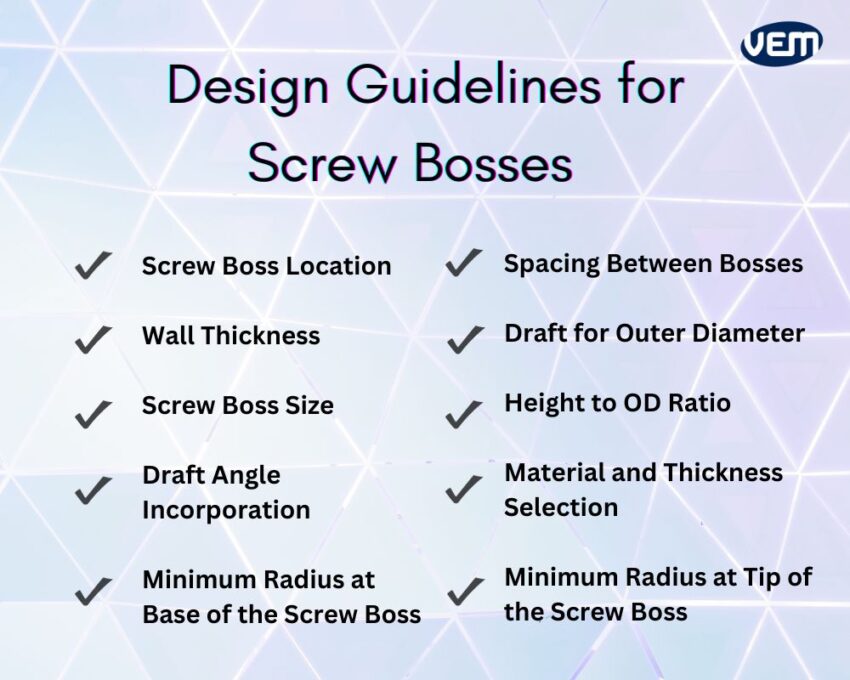

Designing via injection molding technique is an extremely complex process that is dependent upon various factors such as structural and functional requirements, process constraints, and material selection. It also involves the assessment of various variables such as wall thickness, draft, bosses, and ribs. In this article, we discuss some guidelines for designing screw bosses for injection molding techniques. These design guidelines help to improve the design moldability and the mold life.

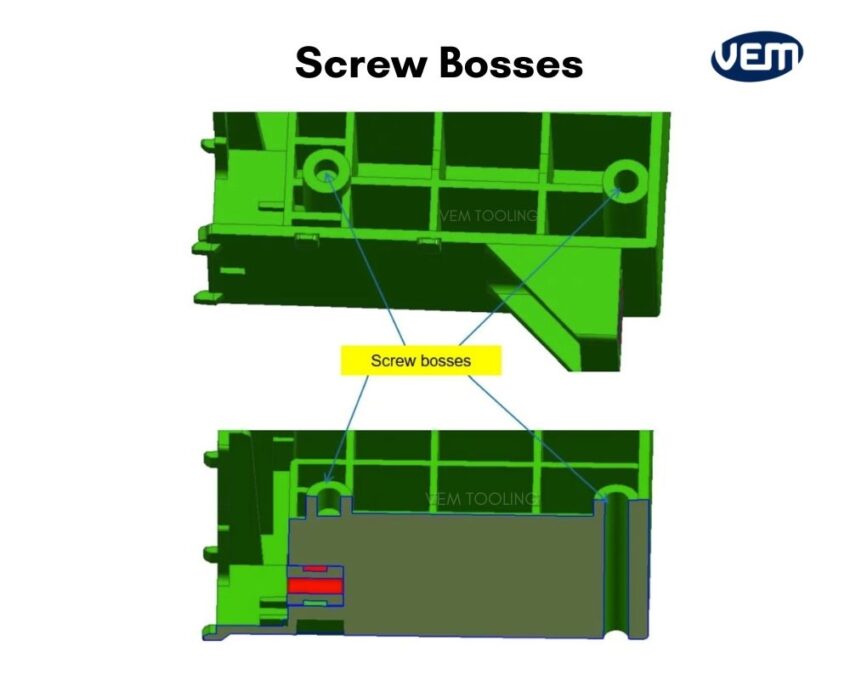

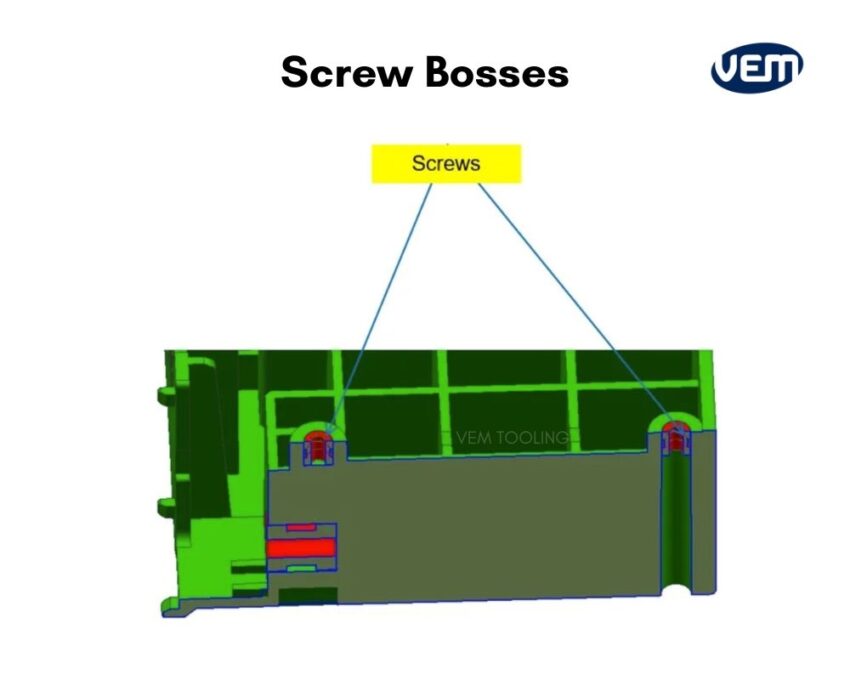

Screw bosses play a crucial role in molded parts as an attachment and assembly point. They are cylindrical protrusions that are typically located on a part’s wall and contribute to various functions such as positioning aids, fixation points, facilitating gear rotation, and acting as bearing surfaces or levers. Screw bosses are cylindrical parts with holes that can accommodate threaded inserts, screws, and other mechanical fasteners.

Screw bosses are required to align the parts during assembly and they create a seamless connection between the plastic parts. They improve design moldability, and part strength and prevent commonly arising aesthetic defects to ensure high-quality plastic parts.

A well-designed boss screw is strong, can be rapidly assembled, and is resistant to part failure. In terms of functionality, it should withstand tension, compression, torsion, and flexing.

When a boss screw is being considered for a molded part, you must consider its function and the type of force that will be applied during the assembly.

There are two factors to consider when manufacturing an injection molded part with a screw boss design. Let’s understand these factors further:

Strength is a crucial design consideration as screw bosses are continually exposed to stress. It is recommended to avoid placing a screw boss close to an external wall.

To improve the strength of a screw boss, you must consider reinforcing it with gussets or ribs. These extra features improve part strength and durability.

You should note that if you are selecting materials for boss screws, then you must prioritize those that demonstrate low and uniform shrinkage. Such materials offer superior dimensional accuracy. Material types that are best suited for screw bosses are those that are soft and less brittle as they can accept screws easily. E.g. If your plastic part comprises polycarbonate which is primarily a brittle plastic, then it is advised to blend it with a softer material such as ABS.

The location of the screw boss determines how this particular feature meets the functional requirements of the part. Let’s take a look at some of the locations that are recommended:

Sinking is one of the most common injection molding defects and to avoid the same, it is recommended that the wall thickness of a boss screw design is approximately 60 percent of the normal wall thickness.

The next design guidelines indicate the correct size of the screw bosses. The screw boss should be of the same size and diameter as that of the wall thickness and the size of the injection-molded part. If the screw boss is smaller in size, then the part strength will be inadequate whereas a larger than necessary size of the screw boss can increase the production cost unnecessarily. You must also consider the type of load of the assembled part! For instance, screws that are longer or with larger diameters have higher carrying capacity than those with smaller diameters.

You must note that the thread diameter represents the screw boss’s outer diameter and is used along with the length and pitch to calculate the size of the screw bosses.

Design guidelines for boss screws suggest incorporating draft angles on the walls of a boss to ensure effortless ejection of the part from the mold. The incorporation of draft angles minimizes any type of damage that may be caused to the molded part. It is recommended that the outer surface of a screw boss should have a draft angle of minimum 0.5 degrees.

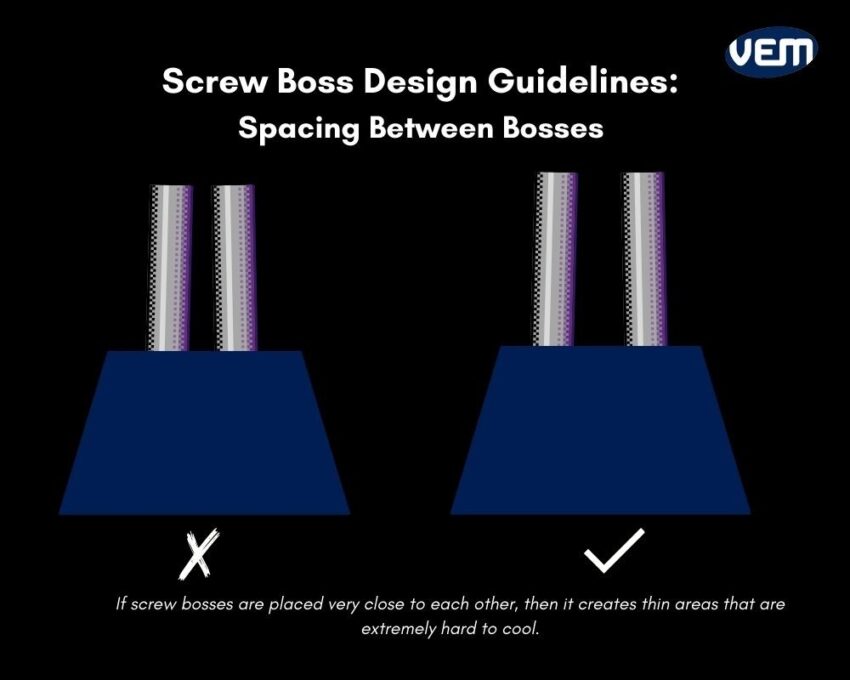

If screw bosses are placed very close to each other, then it creates thin areas that are extremely hard to cool. This extends the cooling time, ultimately impacting productivity and product quality.

In addition, if the mold wall is too thin and the screw bosses are placed very close to each other, then it can lead to hot blade creation and differential cooling thus, it is recommended that the spacing between the screw bosses should be at least 2 times of the nominal wall thickness.

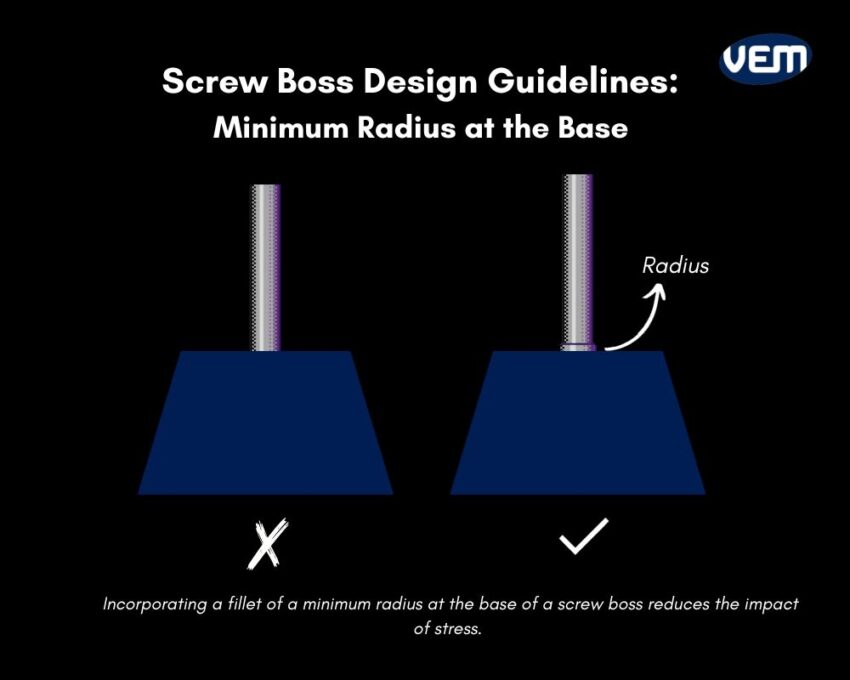

The intersection of the base of the screw boss with the wall is typically stressed. The stress concentration at this intersection increases if no radius is incorporated. It is thus recommended to incorporate a fillet of a minimum radius at the base of a screw boss. This helps to reduce the impact of stress.

The recommended guideline for the base of a boss is 0.25 to 0.5 times the nominal wall thickness. If the radius at the screw boss’s base exceeds a maximum value, then thick sections can occur. In addition, a fillet of a minimum radius should also be incorporated at the tip of a boss to reduce further stress.

A minimum draft is required on the walls of a screw boss to enable easy withdrawal from the mold.

The design guideline recommends that the minimum draft value on the outer surface of the boss should be at least 0.5 degrees or more.

If a screw boss is tall with an integrated draft, then it creates a material mass and a thick section that is challenging to cool at the core pin. This impacts the dimensions of the cored hole. Thus, it is critical to consider the height-to-OD ratio. The recommended design guideline for the boss height is less than three times the outside diameter.

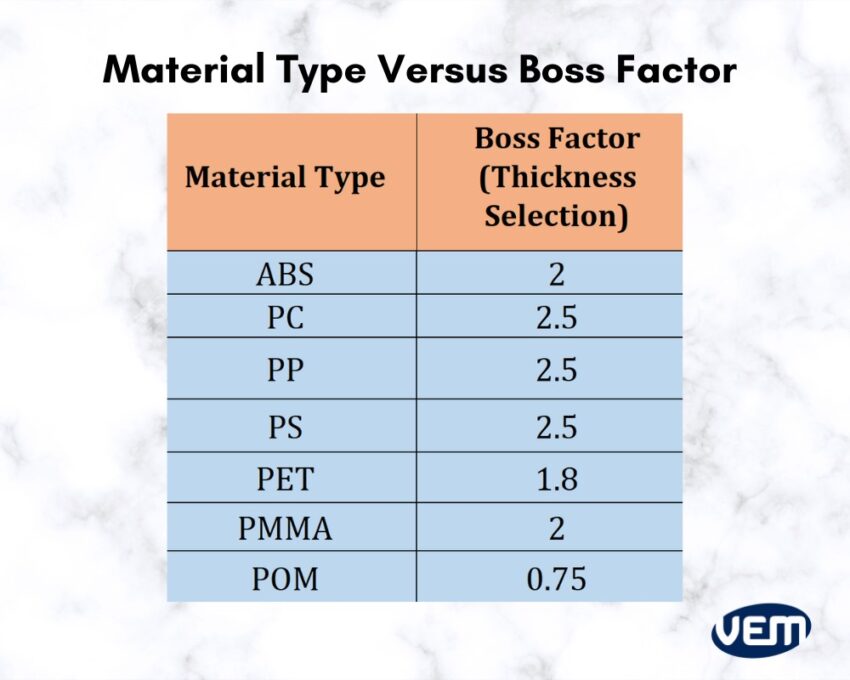

Various materials are incorporated for manufacturing injection molded parts. It is, however; recommended to use similar material for both the part and the screw boss. This guideline enables to enhance the part integrity and stability. The following table enlists the ideal thickness of some of the most popular injection molding materials:

Sink marks are one of the most commonly observed injection molding defects when implementing boss screws as they occur in thick plastic sections where the outer wall intersects with the internal part features.

You should note that sufficient wall thickness must be considered to prevent sink marks in injection molding. This ensures that there is enough molten plastic to support the boss screw when the pilot hole is cut or fasteners are inserted.

Plastic warpage is another commonly observed injection molding defect and is usually a dimensional distortion that occurs at the end of the injection molding process.

You can incorporate fillets and ribs to secure the screw bosses and thereby, reduce the risk of warpage.

The cycle time is the complete duration from mold clamping to the ejection of the plastic part. A longer cycle time leads to an increase in lead time which is generally not preferred.

The incorporation of a screw boss typically extends the cycle time as its presence increases the time required to fill the mold. Though this is not observed as a critical challenge, it is accounted for during the part designing.

Differential cooling between the thin and thick sections of an injection molded part leads to various types of injection molding defects. You should note that screw bosses often have thicker dimensions, which prolongs the cooling time than the thinner sections of the part.

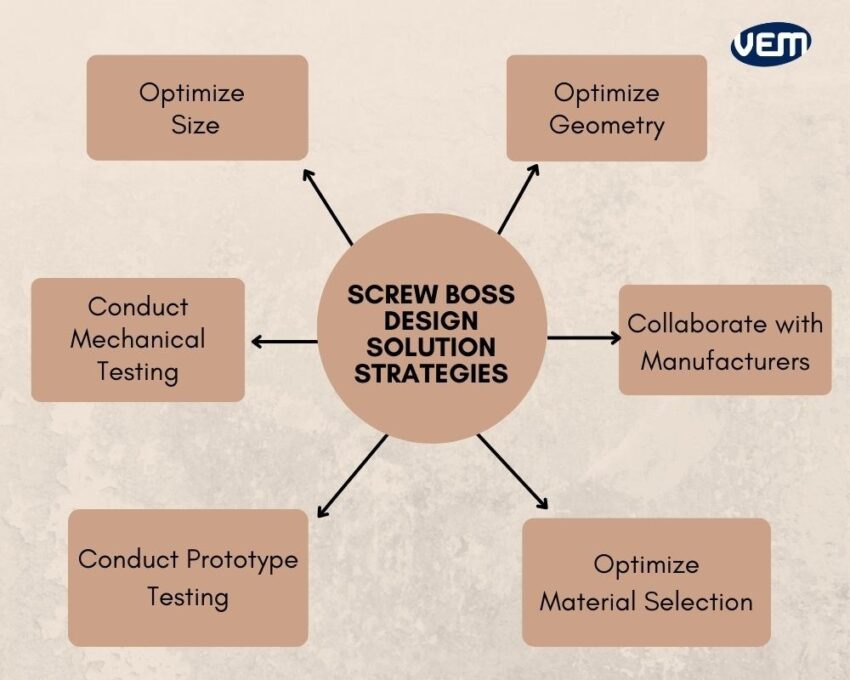

Let’s understand the several solutions that can be implemented to address some of the most common challenges while implementing a screw boss design:

If the screw boss is too small or weak, it can create various issues such as thread failure or altered part strength. It is important to note the correct size and alter or increase the size of the screw bosses accordingly. This solution strategy helps to provide more material strength and improve the overall integrity of the screw boss.

In addition, the geometry of the screw boss must be further optimized to enhance its strength. Various factors such as draft angles, wall thickness, and fillet radii must be considered to ensure stress distribution.

The next solution strategy should be to choose the correct material. The right material will have suitable mechanical properties and it should demonstrate good strength, stiffness, and chemical resistance. All these criteria ensure that the screw boss can withstand the applied load.

One of the most effective solution strategies is to conduct testing. Mechanical tests, such as pull-out or torque tests, assess the strength and reliability of the boss whereas prototype testing of the screw boss design gives valuable insights to validate its performance.

The next solution strategy is collaborating with experts in screw boss design and production. Discussions with suppliers and manufacturers can be extremely productive and of valuable insight as they can provide guidance, suggest improvements, and educate about material selection and manufacturing processes.

Screw bosses need to be carefully designed as they deliver part strength but they are also extremely fragile. If you need high-quality plastic parts with reliable screw bosses, then we can help you meet your requirements.

VEM-Tooling has vast experience in delivering high-quality injection molded parts. At VEM-Tooling, we have an experienced team of engineers who can help you with a wide range of customization options to ensure your parts meet the project’s specific requirements!