It’s imperative that your supply chain operations are designed seamlessly so that it operates like a well-oiled machine! A breakdown in the manufacturing chain can halt production and ultimately, affect deliveries. This is known as supply chain disruption!

Supply chain disruptions can cause not only delays in product shipment but also lead to an increase in customer complaints and revenue loss. Today’s supply networks are complex and thus, disruptions in the supply chain are complex as well.

Supply chain disruptions can be extremely unpredictable, and impactful. They stem from various factors that can range from serious situations such as natural disasters, global pandemics, economic upheaval, political decisions, and cyber attacks, to simply customer requirement changes. In this article, we explain supply chain disruption, its various reasons, and how to plan for it accordingly.

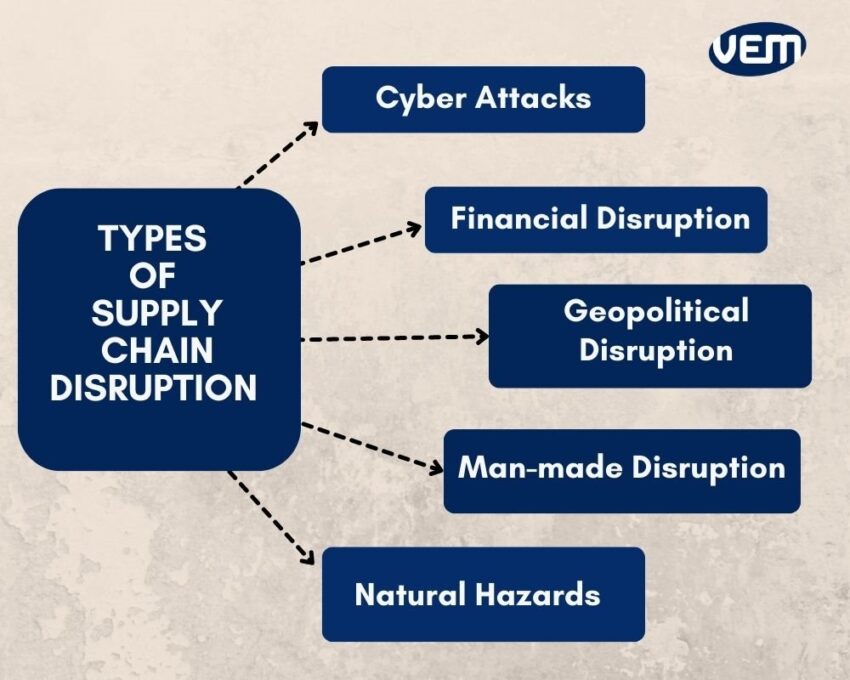

Disruption of the supply chain occurs when an external or internal force interrupts the production and businesses’ ability to ship, and/or sell products to the consumer. While an internal force is usually an internal matter of the company, an external force can be any event that was not intentionally created but is implementing a direct or indirect change to your supply chain. For e.g. the recent COVID-19 pandemic, which was an unforeseen event disrupted supply chains for various businesses. Another instance is if there is a cyberattack on your IT system. These types of events can halt production and compromise security. Let’s understand further, the 5 types of supply chain disruption:

There are 5 significant types of supply chain disruption. These risk categories can either be internal to the company, such as massive product recalls or they could be external threats such as power outages, or natural hazards. Let’s understand these five risk categories:

These types of attacks include threats such as ransomware and data theft and they are a rising cause of supply chain disruption. One of the most typical cyberattacks is done by attacking third-party suppliers that are considered to have the weakest cybersecurity measures. You should note that these vendors are generally cyberattacked if they are connected to the actual target.

This risk category includes threats such as force majeure (FM) and revenue outlook. Today, suppliers rely mostly on force majeure clauses to suspend their obligations which is why many businesses are facing disruption. Thus, you should always note to ensure that FM clauses are drafted carefully.

This risk category includes threats such as civil unrest and tariff hikes, bad weather, and geopolitical friction. Geopolitics has always impacted the logistics of the supply chain, but due to the pandemic, it has played an even bigger role in supply chain disruption.

Man-made disruptions cover all types of risks that can be intentionally or unintentionally induced by man such as fires, explosions, political instability, elections, and labor strikes. These types of disruptions have a significant impact on the supply chain and they hold the potential to not only disrupt but completely shut down businesses. Additionally, global companies often face a business continuity threat if critical suppliers are stationed in countries that often undergo these types of unrest.

Supply chain disruptions include natural disasters such as extreme weather, earthquakes, flooding, hurricanes, and fires. Depending upon the severity, natural hazards can either disrupt or completely halt the supply chain of a business.

You should note that there may be many threats that cannot always be categorized as just under 1 type. They may be a combination of these types. For instance: Raw material shortages caused due to environmental changes and financial disruption.

Supply chain disruption leads to revenue losses. It also hinders the brand image when products do not reach customers in a timely manner. This often nudges customers to look for other options in the market.

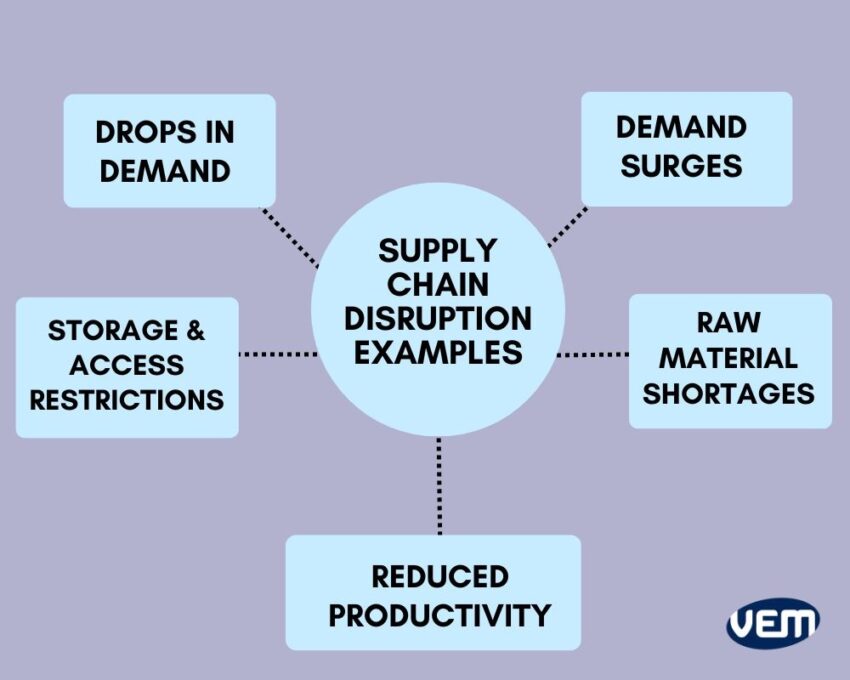

In this section, we enlist some examples of supply chain disruption. These examples are disruptive events that present dependencies of businesses. These examples further, provide a holistic understanding of supply chain disruption. Let’s understand these examples further:

Product requirements can fluctuate for a myriad of reasons. There could suddenly be a decrease in demand for the product. For instance: Let’s take a look at the airline industry. During the pandemic, the demand for air travel dropped by more than 95% as more and more people stayed at home for safety reasons. This greatly impacted the airline industry as both, essential and non-essential travel came to a halt.

This is exactly the opposite of the demand drop event. It’s inverse such that there may be a sudden increase in product requirement. For instance: The demand for a particular confectionary or spice may spike during the holiday season.

There are various reasons for reduced productivity such as labor or equipment shortages, inadequate training, changes in staff, etc. All these events greatly affect productivity which ultimately reduces business output.

You should also note that it’s not just the internal factors such as employees or equipment that disrupt production levels, but it could also be your key supplier or manufacturing partner thus, it is crucial to evaluate every stage of the supply chain. In addition, you should be proactive to shift to alternative ones.

There are times when manufacturing plants face contamination issues. During such times, warehouses need to be shut down and these types of restrictions are often due to natural disasters or viral outbreaks. For instance: During the pandemic, Amazon closed its warehouse that used to handle returns in Kentucky. This disrupted the chain leading businesses to make substantial changes in storage and product handling.

Natural hazards or geopolitical changes can cause raw material shortages. It can greatly affect your ability to source raw materials. In order to mitigate the risk of this type of disruption, you should always evaluate your strategic sourcing plan thoroughly and ensure to include procurement partners in other countries.

We have discussed various examples of disruptions in the supply chains. Now, let’s take a look at some of the case studies. COVID-19 significantly impacted the supply chain of various businesses. It not only affected businesses but caused significant damage to the global economy.

These case studies represent events that led to major deviations due to disruptions in the supply chain. They also explain what was done to adapt to these changes. Let’s take a look at some of the supply chain disruption case studies:

Challenge:

During Covid-19, Kellogg Co., an FMCG giant experienced a shift in their bulk volumes. The requirements were shifted from schools and restaurants to homes. People had started working from home and thus, the demand had shifted. The pandemic had boosted sales for various categories i.e. snacks, cereals, and noodles so a demand surge was observed. In this case, the challenge was sourcing more paperboard packaging for their cereal boxes.

Solution:

The region’s supplier could not deliver the packaging due to shipping delays that were caused by the pandemic. Thus, the procurement team opted for alternative solutions by locating a new source of paperboard. They found an alternative supplier in New Zealand which also helped to lower the transportation costs as it was geographically closer.

You can read more about the case study here.

Challenge:

Sportswear brand Nike experienced a massive hit during the COVID-19 pandemic in its distribution, logistics, and third-party manufacturing operations. Nike’s shipments to their wholesalers were reduced. They also experienced labor shortages and increased production costs. These were some of the challenges faced by the company.

Solution:

The company overcame these challenges by shifting its point of sale from wholesale to direct online sales. They expanded these segments more, since the profits here, are 10% higher than wholesale. They also offered discounts and focused on improving their supply chain network such that the products were closer to the consumer.

You can read more about the case study here.

Challenge:

A Cyberattack named Notpetya was released in 2017. This virus was designed to attack the computer networks of Ukrainian banks, and the government but after it was decoded, the malware spread across various entities and affected customers around the world. It disrupted the supply chains of various businesses, especially the shipping companies. This malware ultimately resulted in an economic loss of 10 Billion Dollars globally.

Solution: The Notpetya cyberattack not only interrupted but affected businesses on a global scale. This attack disrupted the supply chains such that affected customers opted for new, alternative suppliers. They also terminated business relationships with suppliers that were directly hit in order to protect their business.

You can read more about the case study here.

Additionally, various tool-makers also experienced challenges during the pandemic. There were very few new orders and only low-order volumes. Our chairman, Mr. Marc Weinmann has discussed these challenges, growth, and opportunities here.

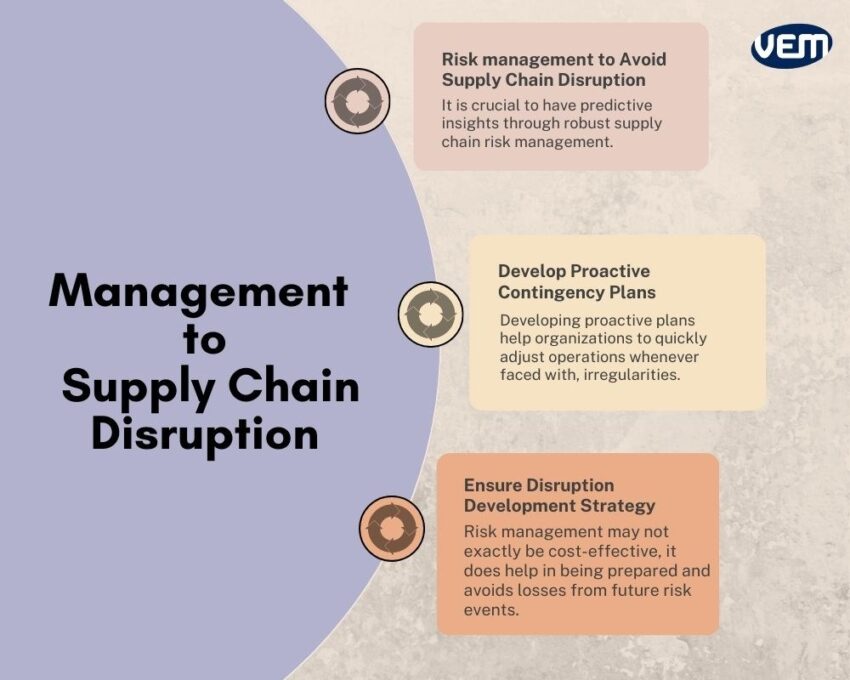

The management of supply chain disruption is largely dependent upon, ‘how fast companies react to events?’ Thus, artificial intelligence-based software plays a major role in the management of disruptions.

It is crucial to monitor suppliers and pay attention to weather forecasts, and trade union activity. These help to indicate threats and identify disruptions. Companies can also reduce the severity of disruption by developing risk-aware strategies. These activities help to make the supply chains more resilient. Let’s take a look at some of the ways to manage disruptions:

The first step should be always prepping your supply chain to identify threats and risks in order to avoid supply chain disruption in the first place. It is crucial to have predictive insights through robust supply chain risk management. It helps businesses to mitigate disruption by reacting faster to events. This, in turn, helps businesses to stay ahead of the competition.

You should note that businesses that are prepared for risk are able to repair their supply networks faster! Effective risk management includes the following:

It is crucial that you are aware of the various kinds of risks that are associated with supply chain management so that you can develop contingency plans. These contingency plans will help you to make proactive plans that in turn help to address business emergencies.

Developing proactive contingency plans help organizations to be flexible enough to quickly adjust operations whenever faced with irregularities.

One of the most common hindrances that are often faced while developing a disruption strategy is that maintaining effective risk management is often at a crossroads with increasing the cost efficiency of the supply chain. You should, however; note that emergency expenditures tend to be higher than supply chain risk management investments. Thus, even though risk management may not exactly be cost-effective, it does help in being prepared and avoids losses from future risk events. Thus, it is crucial to ensure a disruption development strategy.

You should note that it is crucial to be prepared for risk management as it drastically improves the response time, if and whenever a disruption occurs. Here are some steps that you should note in order to mitigate and manage risks:

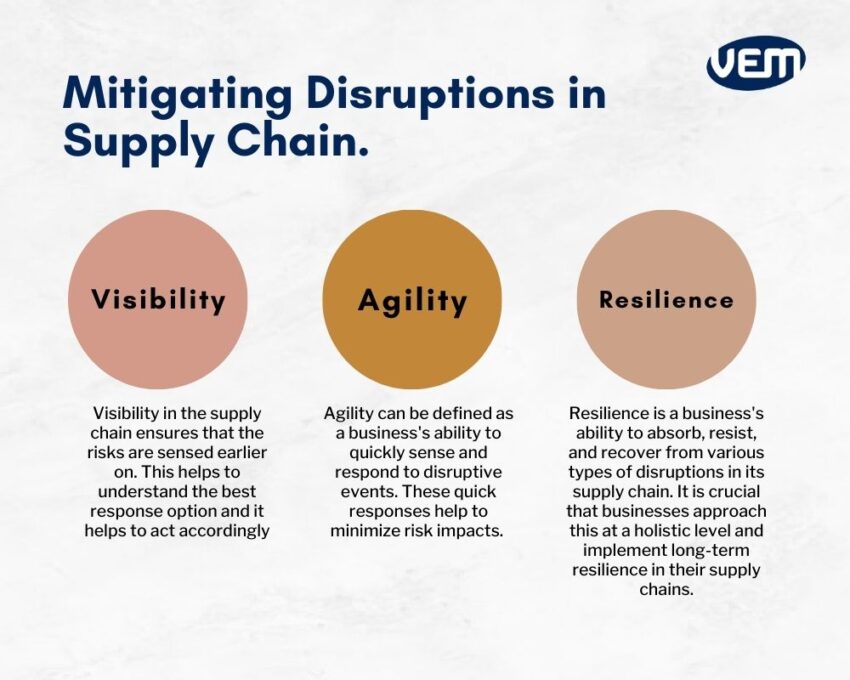

Supply chain disruption can be mitigated by ensuring visibility, agility, and resilience in the entire supply chain. You should note that such measures reduce supply chain disruptions drastically. Let’s understand how can this be achieved:

The first key factor in mitigating supply chain disruption is ensuring visibility across the supply chain! Visibility in the supply chain ensures that the risks are sensed earlier on. This helps to understand the best response option and it helps to act accordingly. One of the ways to achieve end-to-end visibility is by implementing an integrated logistics control tower. This ensures relaying real-time visibility into operations.

The next key factor in mitigating disruptions across the supply chains is agility. Agility can be defined as a business’s ability to quickly sense and respond to disruptive events. These quick responses help to minimize risk impacts. In order to implement agility, a thorough supply chain risk assessment needs to be conducted. You should ensure to diversify your supplier base, build up a contingency stock, and identify backup suppliers.

Finally, it’s all about resilience! Resilience can be defined as a business’s ability to absorb, resist, and recover from various types of disruptions in its supply chain.

It is crucial that businesses approach this at a holistic level and implement long-term resilience in their supply chains. They should aim to incorporate flexibility and include technology-led responsive risk management systems to achieve this. The implemented systems should leverage technologies such as applied analytics, artificial intelligence, and machine learning.

Supply chain disruptions can occur in any type of business, no matter the company size. It’s crucial to thoroughly review the stages of your supply chain, and its disruption plan and ensure that you’re taking measures to mitigate these types of disruptions.

Today, businesses are making use of more digital platforms to introduce real-time monitoring and end-to-end inventory visibility. If you’d like to understand how to incorporate these types of platforms and strengthen your plan, you can explore current systems in VEM tooling.