Custom injection molding is a highly efficient manufacturing process for designing and producing high-quality plastic parts to meet specific requirements. It involves injecting molten resin into a pre-designed mold, which further cools and solidifies to form the part.

There are various consideration factors when discussing a custom injection molding project, which may range from choosing the correct materials to deciding the surface texture, and more. In this article, we discuss these parameters and include a detailed checklist of the considerations.

It is essential to establish and categorize custom injection molded parts to ensure the correct technique is applied.

Don’t forget that there are various aspects to part design, which is why categorizing the custom injection molded parts correctly is of prime importance. To categorize custom injection molded parts, you must define the purpose and requirements of each part. Let’s understand this further:

It’s critical to understand the end-use of the part, i.e., the operational environment of your part. Understanding the part’s end use enables manufacturers to narrow down various decisions regarding material, design, and tooling. You can ask the following questions:

These questions help manufacturers to understand if the designed and manufactured parts are required to demonstrate biocompatibility, chemical resistance, or heat resistance. For instance, A cosmetic casing may require the part to be functional w.r.t hinge strength, but it also needs to display aesthetic appeal, whereas a medical device casing needs to demonstrate a smooth finish, but also should demonstrate biocompatibility and chemical resistance as it’s in contact with bodily fluids.

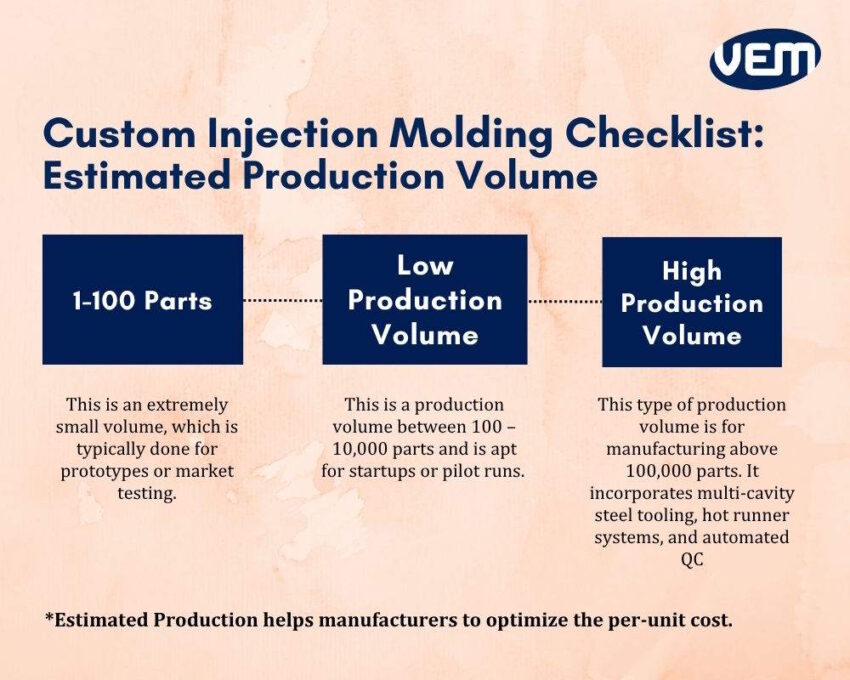

The estimated production volume enables manufacturers to analyze the type of custom injection molding process and mold material that should be used to manufacture the part. It also helps to optimize the per-unit cost. Let’s understand this further:

Custom plastic injection molding allows for great precision, but you should note the tolerance level that is required for the part. Identifying critical vs. non-critical tolerances in features can simplify the mold design and save on costs. Some of the best practices are to incorporate tolerance callouts on 2D drawings and balance form and function.

The surface finish of the plastic part affects the part’s aesthetics and the end user’s feel. It is thus an important aspect of the custom injection molded part and should be included in your checklist. The infographic below indicates the various types of surface finishes and their applications:

The required finish should be correctly documented and should include details such as texture location, pattern type, and roughness level.

The next question to ask is whether the custom injection molded parts that will be manufactured should be reusable or are they for single-use. Let’s understand these aspects further:

You should note the various categories of injection molding processes, and an early and accurate classification of the part with the process ensures an overall alignment in terms of design and manufacturing.

This type of custom plastic injection molding process is for thick-walled plastic parts to enhance part strength. You should note that the thick-walled injection molding process ensures uniform material distribution so that the wall thickness is even, which avoids the occurrence of injection molding defects.

Thin-wall injection molding is employed to manufacture plastic parts that typically have less than 1mm of wall thickness. It’s an extremely niche and advantageous technique for producing thin and lighter parts. You can read more about thin wall injection molding here.

Transparent parts are typically required to be aesthetically pleasing, which is why it is crucial to avoid flow marks and gate blush. Injection molding ensures to include such aspects to manufacture high-quality transparent parts.

Insert molding involves embedding material inserts into the part. It’s often applied to parts that need to demonstrate enhanced mechanical properties or electrical conductivity.

Overmolding is suitable for plastic parts that require two different materials or colors. It involves molding more than two components with each other, and you can read more about overmolding here.

Micro injection molding is applied for extremely small parts, and thus, specialized injection molding machines are incorporated to manufacture these parts. You can read more about micro injection molding here.

The above types of custom injection molding processes demonstrate a general overview of the processes for product development. They, however, overlap to achieve the required part specifications.

The next aspect in the custom plastic injection molding is to select an appropriate resin. The material for your custom plastic injection molding process should be chosen based on various factors, such as functional requirements, chemical and environmental exposure, thermal resistance, mechanical strength, flexibility, and cost constraints.

It’s crucial to select the correct resin as it directly affects the part’s aesthetics, strength, flexibility, and durability. If the correct material isn’t selected, it can lead to various injection molding defects such as cracking, warping, discoloration, etc. Selecting an appropriate resin further saves time and money, which is why it is crucial to correctly evaluate and select an appropriate resin. You should note that material behavior also influences the mold design and cycle times.

Many high-performance plastics are extremely hygroscopic in nature. They tend to absorb moisture from the air, which can cause cosmetic defects. It’s thus imperative to follow the guidelines for material-specific drying times and temperatures.

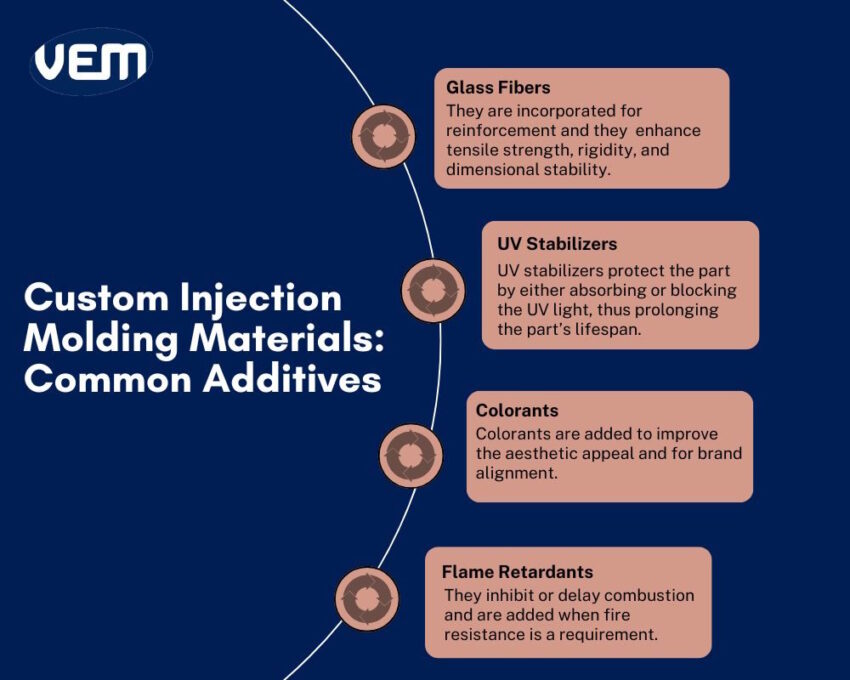

Let’s understand some popular additives for custom injection molded parts:

Glass fibers, often abbreviated GF, are incorporated in the resin for reinforcement. They significantly enhance the rigidity and dimensional stability of the material they are incorporated into.

Resins reinforced with glass fibers are especially useful for structural or load-bearing components such as automotive housings, electrical enclosures, and industrial machinery parts. For example, PA66 GF30, i.e., Glass-filled Nylon, is popularly applied in automotive engine parts due to its high strength and thermal resistance.

When the part’s intended use is for outdoor use and is continually exposed to the sun, it’s susceptible to UV degradation, which can cause brittleness, fading, or loss of mechanical properties. UV stabilizers in resins protect the part by either absorbing or blocking the ultraviolet light, thus prolonging the part’s lifespan.

Colorants are added to resins for various factors, such as improving the aesthetic appeal and brand alignment. They are available in various forms such as liquid, powder, or masterbatch pellets. To achieve opaque, translucent, or metallic finishes, colorants can be tailored to the specific use-case.

Flame retardants are additives that inhibit or delay combustion and are especially common in electrical, automotive, and construction applications. They are added to the resins when fire resistance is a regulatory or safety requirement.

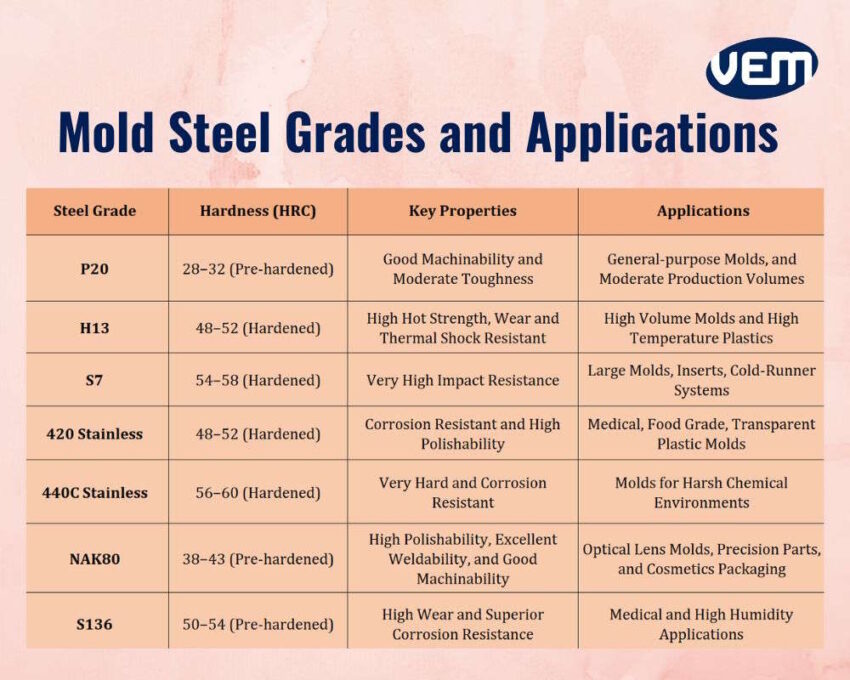

Mold steel has a direct impact on the cost and quality of the production process. The infographic below indicates the popular types of mold steels:

It’s imperative to include and optimize gate and runner design in your custom injection molding checklist. Gate design and runner systems govern how the molten resin flows and fills into the mold. They largely impact the aesthetics and structural integrity of the final part.

It is crucial to note that the type, size, and placement of gates are tailored to the part geometry. You can read more about the types of injection molding gates here.

The gate design is further optimized by the runner systems, which enable molten resin to enter the gates from the sprue. There are two types of runner systems: Hot runners and Cold Runners. Cold runners are simpler and more cost-effective, but the resin solidifies with every cycle, whereas hot runner systems keep the resin molten through heated channels, thereby reducing waste and cycle times, making them ideal for high-volume production runs.

The longevity and performance of a mold are directly impacted by its maintenance. If the maintenance is neglected, it can affect the mold’s longevity and can also lead to unscheduled downtime and part defects.

A mold design review checklist should be established to ensure timely tool maintenance.

There are several ways to conduct an inspection. Let’s understand some inspection protocols that enable manufacturers to perform the checks:

Mold flow simulation is a predictive tool that demonstrates the flow of molten resin within the mold cavity. It enables engineers to identify potential issues early on and thereby optimize the design.

In addition to optimizing the design, mold flow simulation reduces the development time and iteration cycles. You can read more about mold flow analysis here.

The established process for manufacturing the part must be reliable and affordable. DFM, abbreviated for Design for Manufacturability, is the process of identifying and preventing errors, thus improving costs and efficiency.

It’s a continuous process that optimizes the design to minimize defects and improve performance. You can read more about DFM here.

Automation can be considered to improve upon efficiency of the custom injection molding process. It’s especially effective for high-volume production runs, where speed and accuracy are paramount. Some of the key automation strategies include:

Quality standards should be established as per the industry and regulatory requirements. You should note to clearly define the quality standards for production and inspection.

These standards must include aesthetic requirements and dimensional accuracy, and all the criteria should be documented and communicated across design, QA, and production departments.

Cost estimation is a crucial aspect of custom plastic injection molding. Let’s understand these further in detail:

In the case of small volume production runs, mold costs constitute the major expense. The mold costs in small production volume runs are the investment bulk, and you can choose to improve the ROI here with multi-cavity or family molds.

In the case of large volume production runs, the production processing costs are prominent, and to ensure continuous production, it’s cogent to improve the mold quality so that it can withstand continuous production. You can optimize the costs by reducing the injection molding cycle, increasing the number of parts produced per mold, implementing automation equipment to reduce labor costs, and maintaining efficient mold operation.

Custom injection molded parts may need to undergo post-processing and secondary operations. Let’s understand some of the popular post-processing and secondary operations:

Surface treatments include two types of techniques, such as surface coating and printing.

Welding techniques improve the structural strength of the product by joining different plastic parts together. Some of the popular custom plastic molding techniques are ultrasonic welding, friction welding, and heat welding.

Mechanical processing includes milling to remove gate scars. It can also incorporate laser cutting, or drilling holes in parts with complex structures.

Product packaging should consider various factors, including the protection of the part, convenience, and cost-effectiveness. The design of the packaging should ensure that the products are safely packed, protect them during transit, and comply with regulatory requirements.

Single product packaging options typically include cardboard boxes, color boxes, double blister packs, and blister card packaging. These types of packaging can include product information.

Bulk packaging should be designed for stacking efficiency and pallet compatibility. The design should consider placing products such that maximum space is utilized.

Custom injection molded parts often have custom designs that involve proprietary innovation. It’s thus crucial to protect your IP i.e. Intellectual Property. To protect your intellectual property (IP), you should ensure to sign non-disclosure agreements before sharing your designs and choose to work with custom plastic parts manufacturers that define mold ownership and exclusivity. You can also choose to work with custom plastic parts manufacturers in jurisdictions that uphold strong IP laws. This is especially beneficial for long-term partnerships.

You can read more about how to find a good custom injection molder here.

Custom injection molding is a complex manufacturing technology that includes various consideration factors. You need to assess the design and technical capabilities of the custom plastic molding company that you choose to partner with.

VEM-Tooling has over 20 years of experience in custom plastic injection molding and other manufacturing solutions. Our design experts and engineers are experienced in ensuring that every detail in the custom plastic injection molding checklist is considered as per the industry and specific project requirements.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.