Custom plastic injection molding is an extremely advantageous manufacturing technique for producing high-quality plastic parts. It’s popularly applied to an array of industries due to its customizable and cost-effective solutions. It can be applied to manufacture your unique products as per the requirements and specifications.

Custom injection molded parts are manufactured by heating and melting specific resins into well-built molds under high pressure. It’s a precise manufacturing technique that requires expertise and experience. Thus, it’s crucial to select an adept custom plastic molding company.

If the custom plastic molding company you work with isn’t experienced, it can lead to various issues that may range from poor part quality and production delays to increased expenses. In this article, we discuss how to identify, choose, and finalize a trusted custom plastic molding company.

When you are in the process of locating a custom plastic molding company, it is critical to conduct thorough research. It is imperative to identify the correct custom plastic molding company so that it aligns with your project requirements. In this section, we discuss how and where you can locate potential suppliers and manufacturers for your project.

Online directories include an extensive list of suppliers and manufacturers that cater globally to clients. You can apply filters on online directories to search and narrow your research based on customer reviews, certifications, manufacturing solutions, etc.

Some of the most popular online directories are Globalsources.com, Alibaba.com, and Thomasnet.com.

Industry-specific trade shows are a direct way of meeting and evaluating potential suppliers. They educate on the latest trends and technologies that are applied in the industry.

You can also choose to contact a sourcing agent to locate a custom plastic molding company. Sourcing agents can navigate and assist you in locating the best supplier or manufacturer for your requirements.

If you are looking to manufacture in a specific region, you can hire local agents. They can guide you towards the specifics of the region and its industries.

You can seek industry referrals through your trusted network. These referrals can connect you with seasoned suppliers and manufacturers that have been verified by your network.

To gauge the capabilities of potential custom injection molding manufacturers, it’s imperative to ask certain questions that help to verify their suitability for your project. Let’s understand the type of inquiries you can make:

You can ask the custom plastic molding company about its products and services. It helps to identify if the core capabilities of the custom plastic molding company can support your project requirements. In addition, you should also inquire about the MOQ, abbreviated for minimum order quantity, to understand if the selected manufacturer can align with the production requirements.

The next inquiry should be regarding the experience and expertise, i.e., how long they have been providing custom injection molding services and solutions, and for which industries. This indicates the company’s experience in the injection molding and tooling sector.

You should also inquire if they have an in-house design and manufacturing unit, whether they focus on domestic or international activities, their locations, and the size of their personnel.

The technical staff and engineers must undergo consistent training. You can inquire if the personnel are well-trained to efficiently manage the complexity of your projects.

You can inquire about their quality control processes to understand if your custom plastic molding company can deliver high-quality products. The next aspect is to understand if they hold the required certifications and have quality management systems.

You can learn about the services and customer service offered by the custom plastic molding company by checking and asking for their references.

The first guideline for selecting a custom injection molding manufacturer is to outline the volume and capacity of your project. You should note that there are typically two types of custom injection molding requirements. Let’s understand these further:

Low- to medium-volume injection molding is applied for projects that require part production of up to 10,000 parts. It’s suitable for businesses that require part production in small volumes or want to create prototypes for market testing. You should note that lower production volumes may still have MOQs, i.e., minimum order quantities.

High-volume is applied for part production that can run in the hundreds of thousands to millions. It’s suitable for businesses that require part production in bulk quantities.

If you initially select a custom plastic injection molding manufacturer that specializes only in low- or high-volume production runs, then you may need to find another injection molding partner if your product quantity changes.

The next aspect is to understand if your custom injection molding manufacturer can produce parts as per specific applications. You should note that the manufacturers demonstrate expertise in different designs and materials. Let’s understand these aspects further:

You should note the required resin properties for your product. Certain industries require specific resins, which is why injection molders need to have the expertise. These resins not only have different physical and chemical properties, but they also support different part tolerances. For e.g., nylon has different molding requirements than more rigid materials such as polycarbonate.

The part size and geometric complexity are determining factors in selecting a custom plastic molding company. You should note that many manufacturers are skilled in a range of part sizes and complexity; however, the level of precision that is required may impact the supplier selection. You should also note that micromolding is a type of specialization technique that requires expertise, and you can read more about micromolding here.

The manufacturing capabilities of a custom plastic molding company include both the aspects of tooling and machines. They can also provide you with the required tolerances and finishes. The correct custom plastic molding company can explain to you about mold texturing and SPI surface finishes.

The production capacity is determined by the size and number of injection molding machines in the company.

An injection molding machine’s size is referred to as tonnage. If the tonnage is higher, then the production capacity of the parts it can manufacture will be higher and larger.

The next aspect for selecting a correct custom injection molding partner is to identify if they can provide you with value-added services such as design for manufacturability, rapid prototyping, mold design, and material selection guidance. These services ensure that high-quality parts as per the specifications are manufactured. Let’s understand some of these services further:

DFM, abbreviated for Design for Manufacturability, optimizes the design of the part. It increases process efficiency and improves cost-effectiveness. You can read more about DFM here.

It is extremely advantageous if your supplier or manufacturer can create a prototype of your product as per your design and specifications. Rapid prototyping enables manufacturers to create such prototypes for further analysis and production. You can read more about rapid prototyping here.

Mold design is a crucial consideration for manufacturing high-quality plastic parts. It requires expertise to decipher and elucidate the minute details. Your custom plastic molding company should be able to explain various aspects of mold design, such as undercuts, draft angles, and gates.

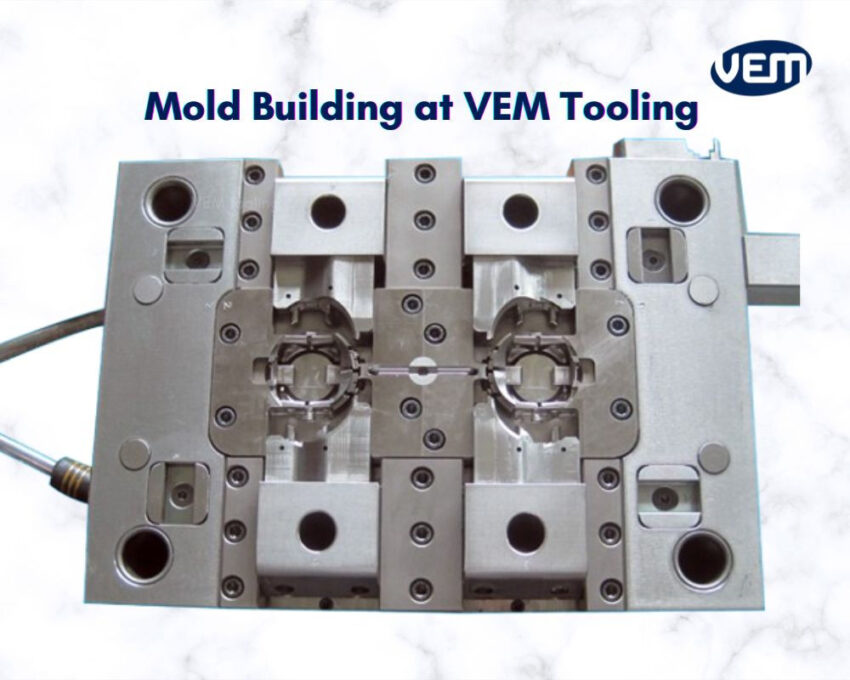

Your custom plastic molding company should be experienced in building tools. The mold is built by an experienced team of engineers to manufacture the product as per the mold design.

Mold flow analysis enables a custom plastic molding company to identify design issues. This data further helps to enhance the part quality and its performance. You can read more about mold flow analysis here.

The exact pricing of your custom injection molding project depends upon various factors such as the production volume, mold size, part complexity, expertise, and the materials used.

Vendors vary in their services and cost, and you can assess quotes from various manufacturers to understand which manufacturer is within your budget. You should note that the custom plastic molding company you choose to partner with shouldn’t compromise on product quality. It is imperative to understand that the cheapest quote may not always be the best strategy in the long run, and it is thus cogent to evaluate various vendors.

It is important to provide manufacturers with the correct project summary. The summary should encompass all the details so that any type of additional charges doesn’t appear later on.

A seasoned manufacturer should be able to make apt recommendations that can reduce costs and lead time without compromising the part quality.

It’s crucial to analyze whether the custom plastic molding company can deliver quality parts consistently. You should note that quality control or assurance isn’t just about the certifications. It’s about ensuring that the product specifications, industry standards, and regulatory requirements are met, such that high-quality parts are consistently manufactured.

You can ask the following questions to your custom plastic molding company:

Typically, an experienced custom plastic molding company has an in-house quality assurance team that verifies the entire process.

When selecting and finalizing a custom plastic molding company for your product, it’s advantageous to evaluate the manufacturing facility. If possible, such a visit should be conducted before finalizing the contract. Visiting the manufacturing facility can provide you with tangible insights into the operations and quality of machinery. It can also help you understand if the manufacturing facility can handle diverse production requirements.

If you are visiting the manufacturing facility, you should plan for sufficient time to tour the facilities and note to focus on the following:

You should check if the equipment is well-maintained. If the machines and technology are well-maintained, then you can expect consistent production of high-quality parts.

Check if the manufacturing facility has the capacity and flexibility to scale operations. This is crucial for fluctuating requirements.

The work environment should be clean and safe. If the work environment is well-organized, it indicates excellent operational ability. You should also inquire whether or not safety precautions are being followed.

Once the supplier has been selected, the contract needs to be finalized. A supplier contract includes some crucial features. Let’s understand these aspects further:

The contract negotiation commences after the selection of a supplier. Negotiating the contract should be approached with specificity and clarity. Every detail must be discussed, i.e., production timelines, quality assurance processes, flexibility for scaling production, costs, etc.

The contract scope of work should clearly outline the services that will be provided by the custom injection molding manufacturer. It should include a detailed description of all the aspects that are required to manufacture the product.

You should look for quality assurance details that specify the quality standards and testing methods that will be applied to your products. These details may range from compliance with industry standards to custom testing procedures.

You should note to protect your designs and patents, especially if you are disclosing proprietary designs. The contract should include details to safeguard your intellectual property.

It is imperative to understand the pricing and payment terms in detail. You should ask questions such as, Do the terms include the pricing on a per-part basis or as an entire project? Can the payment be done in installments?

You should note to ensure that the contract outlines the details of the pricing and payment terms.

The contract should clearly describe the delivery schedules, along with production timelines. Clear communication about the delivery timelines avoids delays.

Custom injection molding is an intricate and complex manufacturing technology. It requires a detailed assessment of technical capabilities to narrow down the custom plastic molding company. With the right manufacturing partner, you can expect production efficiency and consistency in producing high-quality plastic parts.

VEM-Tooling has over 20 years of experience in tool making, custom injection molding, and various other manufacturing solutions. We can deliver industry expertise and ensure that your product is manufactured as per your specific project requirements. Our team of design experts and experienced engineers work closely with customers to understand their requirements and provide valuable recommendations at all process stages.

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.