In the past few years, the manufacturing industry has faced various types of challenges such as supply chain instability, transportation issues, and worker shortages. These challenges can be attributed either due to the changes experienced during and post-covid or simply, due to the advancements in the industry.

The good news, however, is that the manufacturers rose to the challenges and invested in incremental innovation and its implementation. The manufacturing industry has demonstrated resilience and continues to evolve to give rise to manufacturing trends that are altering and advancing today’s global manufacturing landscape!

It’s crucial to have the right technology in place and include only relevant trends in your business. In this article, we discuss the top innovative manufacturing trends that will dominate in 2024-2025 so that you can be agile in a rapidly evolving landscape.

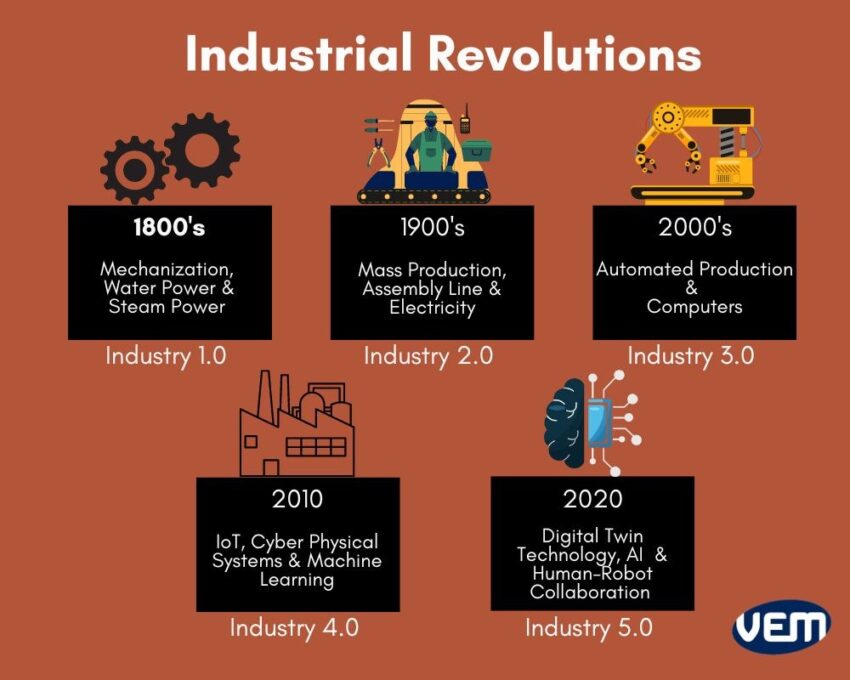

Every industry evolves towards growth and efficiency and such is the case with the manufacturing industry as well! It has observed tremendous evolution since the 1800s. Let’s further understand what are the main drivers for adopting manufacturing trends:

Technological Advancements: Technology has evolved to propel forward! Today, if a business is not applying these technologies, they run the risk of being outdated. The development of new technologies such as automation, machine learning, artificial intelligence, the Internet of Things (IoT), and digital twins has revolutionized the manufacturing industry to evolve further.

Consumer Demand: Today, more and more consumers are demanding personalized and customized products! Customers are opting for manufacturing companies that can not only offer a certain degree of personalization but also cater to their specific requirements. This consumer demand has led propelled manufacturers to adopt new technologies.

Global Competition: The rise of globalization has enforced manufacturers to face competition, from across the world! It has encouraged them to adopt new manufacturing trends that give them a competitive edge.

Environmental Concerns: Over the past few decades, the manufacturing industry has scaled extensively. This has also led to a growing concern about the impact on the environment. Thus, manufacturers are adopting new technologies that help them reduce their environmental impact.

Implementing a new innovation or trend comes with its own set of challenges. Let’s take a look at some of the potential challenges that can be an impeding factor in the implementation of these trends:

Cost and Complexity: Cost and complexity are 2 factors that can be often impeding during the implementation of these trends. Implementing a new technology, innovation or trend can often be expensive. In addition, they can also be complex and may require the expertise of specialized professionals to implement the same.

Change Resistance: New trends and innovations implement new processes which are often met with implementation resistance by the team managers and the employees. One of the ways to enable them to accept these changes is through training and development of new technologies.

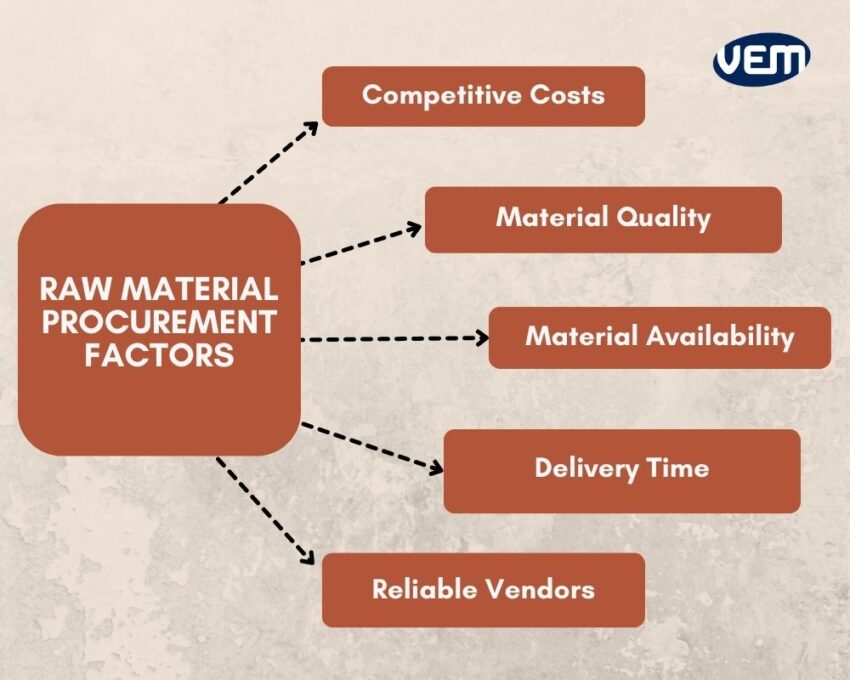

Supply Chain Disruptions: Any type of change in the manufacturing process has the potential to impact the supply chain. Thus, if a manufacturer is implementing any new technology or trend in their process, they must work closely with their suppliers to mitigate potential risks and challenges.

Legal and Regulatory Issues: If a new technology is being implemented, it is imperative to ensure that all processes are in compliance and as per the legal and regulatory requirements. This is again time-consuming and can create complexities.

Now that we have understood the challenges that can be faced during the implementation, let’s understand how you can implement the adoption of new technologies and trends in your present workforce.

Small and medium-sized enterprises (SMEs) need a rigorous plan to implement new technologies and trends. We have outlined and summarized the initiatives that can be taken to implement these technologies efficiently:

The government plays a crucial role in supporting and promoting manufacturing trends. Let’s understand this further:

We have seen the advent of hype in automation, connectivity, and personalization in 2023 but with the advancement of technology, it is expected that all the aforementioned areas will be further accelerated in 2024-2025. While most of the largest manufacturers have already implemented high levels of automation, smaller manufacturers are still trying to catch up.

Let’s understand this further and how will it affect and benefit the manufacturers:

The very first hallmark of the manufacturing industry with respect to automation is recognized when Henry Ford in 1913, introduced automation in its car production assembly line.

Since then, various innovations have been introduced and implemented by many companies in their manufacturing units.

While the trend until now has been to focus on robotics to maximize efficiency and reduce errors, there are other avenues in automation being prioritized. One of them is Cloud Computing!

Euromonitor estimates that in the next 5 years, 62% of companies are likely to invest more in cloud computing. You can read more about the same here, in this article.

Cloud computing is an integral aspect of cloud automation. Cloud automation refers to applying cloud management tools to reduce manual interference. Some of the tasks that can be achieved through cloud automation are auto-provisioning servers, backing up data, and discovering irrelevance in processes in order to eliminate the same.

The goal of cloud automation is to improve performances in processes and production, enhance customer satisfaction, and improve product traceability. In order to implement cloud automation, it is crucial to outline the right strategy and management structure.

You should note that hyper-automation is not about simply investing in cloud automation but it is rather an orchestrated synchronization of various other technologies such as AI, sensors, and machine learning. These technologies take over manual tasks to bring in more visibility. Hyper-automation technologies also bring in more scope for innovation by automating repetitive workflows thus, enabling your workforce to focus on more complex tasks!

Hyper-connectivity is another trend that we will be observing more and more in the upcoming year! Hyper-connectivity is all about closing communication gaps between employees, managers, devices, systems, and processes. The goal of hyper communication is to enable a smooth flow of data at all levels and between different processes.

Why should you think about implementing hyper-connectivity for your manufacturing business? Well, today more and more businesses are defaulting on increased efficiency due to the ‘Information Silo’. An information silo is referred to as an information management system that is unable to communicate with other systems.

Information Silos occur when the various units of an organization make isolated decisions! To elaborate further, systems are not in sync and they, thus make decisions in isolation from each other. You should note that communication within an information silo is vertical, thus, it is unable to communicate with unrelated systems.

Hyper-connectivity connects disparate data sources and enables better coordination within the systems.

A business that knows its customer can design and deliver better products to their customer.

Hyper-personalization is achieving more and more traction as it enables businesses to deliver products that are more customer-driven thus, giving them a competitive edge. It makes use of various technologies such as real-time data, and predictive analytics to get more accurate information about the customer.

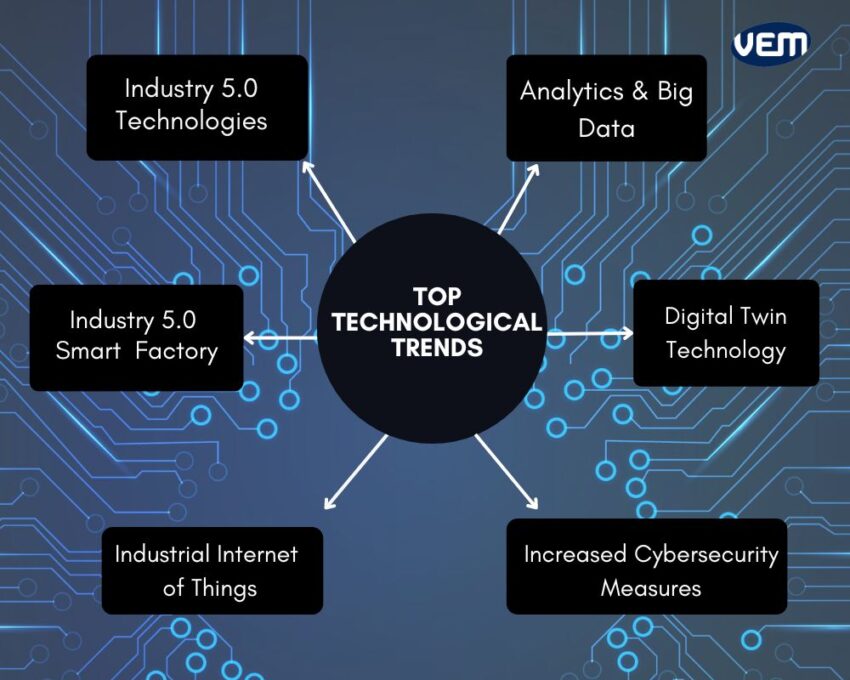

While industry 4.0 technologies such as the Internet of Things (IoT), artificial intelligence (AI), and robotics will continue to be implemented in 2024-2025, 5.0 technologies will further make their way to build more flexible and efficient production systems. Industry 5.0 technologies will provide sustainable and resilient solutions to prioritize collaborations between employees and machines through cyber-physical systems.

The strategy of Industry 5.0 smart factory strategy will be built upon the Industry 4.0 strategy. It will make use of deploying IoT technologies in manufacturing facilities, use AI to collect data and analyze data via cloud computing.

The main strategy in Industry 5.0 technology would be to automate processes through the use of universal robots on the factory floor. The application of technology will allow for more efficient use of resources, reduced waste, and improved quality control. It also helps to reduce repetitive tasks and eliminate dangerous ones thereby, freeing the employees to take on more value-added activities.

Today, manufacturing companies have the ability to collect data from various sources and when this data is combined with extensive and deep analytics, it enables the businesses to get a comprehensive understanding of their business. Thus, big data and analytics will seek a continuum. In fact, it is also estimated by Business Wire in this article, that the manufacturing analytics market will reach from $5.9 billion in 2018 to $28.4 billion $ in 2026.

It is thus crucial for manufacturing companies to leverage advanced analytics. It helps them to gain critical insights and arrive at sound data-driven decisions.

Industrial IoT (IIoT) is an extension of IoT to industrial applications and is today, a leading manufacturing trend and is expected to grow! Grand View’s Market Research Report states that the market size for global IIoT will expand at a 23.1% CAGR from 2022 to 2030.

IIoT enables manufacturers to interconnect unique devices within an already existing internet infrastructure. This allows them to access real-time data and make strategic decisions. Let’s take a look at some of its applications:

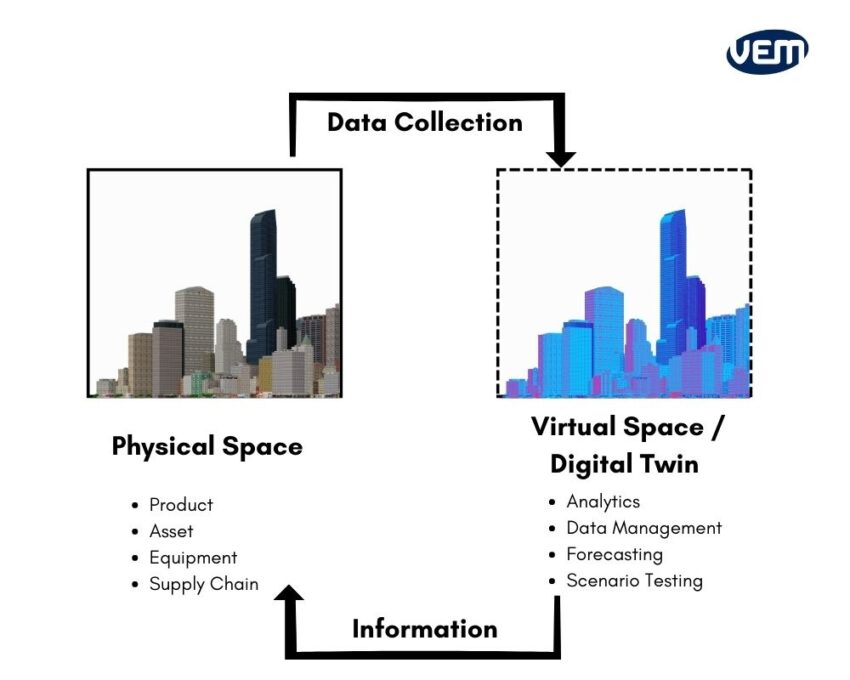

IoT and Machine learning has led to the creation of another leading technology i.e. Digital twins!

Digital twin technology refers to virtual replicas of any physical product, asset, equipment, or supply chain. This virtual replica can be used to improve decision-making through data-driven simulation. Manufacturers can also use these simulations to understand the performance of equipment under varying conditions. For instance: Rolls-Royce uses IoT technology to build digital twins in order to collect critical data and keep tabs on over 13,000 civil aerospace jet engines. You can read more about this case study here.

Since the digital twin mirrors the real property in appearance and in functionality, the simulation enables manufacturers to run tests, enact scenarios and conduct training. Let’s understand its various applications:

Digital twins technology has a wide array of applications which can range from predicting a product’s life based on its design to managing and optimizing operations of an entire factory through simulations.

New technology trends have exceptionally evolved the manufacturing industry. It has led to higher productivity, increased efficiency, and greater visibility. You should note that new technologies have also created an increased need for cybersecurity measures as the entire process is dependent upon interconnected devices and data networks thereby, increasing the threats of cyberattacks. Cyberattacks are extremely risky as they leak information and can cause downtime.

IBM’s Security X-Force Threat Intelligence Index 2023 reported that 30% of extortions targeted the manufacturing industry. According to experts in the IT industry, the manufacturing industry makes an attractive target for cyber-attacks due to the industry’s low tolerance for downtime.

Due to the implementation of new technologies and as more systems interconnect, the manufacturing industry will become even more vulnerable to attacks. Cybercriminals and hackers can attack either the software, firmware, or hardware or all three. Thus, there will be an increased need for strong cybersecurity measures!

The manufacturing industry has evolved at speed and scale across the globe! Though this has increased employment and benefitted the global economy, it has inevitably placed extensive pressure on the environment. Let’s understand some of the manufacturing trends that are associated with environmental impacts:

A fraction of direct carbon emissions are caused due to manufacturing companies because until now, many companies have followed a linear model that relies on fossil fuels, overproduction, and excessive waste. This model is referred to as the ‘take-make-waste’ model, but more and more manufacturers are adopting a ‘sustainable circular economy’ model.

This model is based on 7 R’s: Rethink, Redesign, Repurpose, Repair, Remanufacture, Recycle, and Recover. This model is applied at each stage of manufacturing to reduce waste thereby, significantly diminishing a company’s carbon footprint.

A sustainable circular economy model primarily promotes sustainability while optimizing efficiency across the entire lifecycle. It makes use of technologies to automate processes and streamline operations.

Not only are manufacturing companies trying to achieve carbon neutrality through a sustainable circular economy but there are many that are considering moving towards zero-carbon transformation systems.

You should note that in order to secure a transition to net zero emissions, an increased effort will be required to move towards solar panels globally. This is a trend that will be observed as we progress toward 2024-2025.

Today’s manufacturing solutions are progressing rapidly! There are new technological advancements every year so in addition to implementing these, what should be an effective strategy for your business? We have outlined some assessment aspects below to help you build a strategy for your business:

To flourish in 2024-2025, it’s crucial to make a note of the prominent manufacturing trends so that you can plan ahead and invest your resources aptly.

Even though we are not a service for manufacturing automation, our factories have implemented various manufacturing solutions. This leads to high quality products (Molds & plastic parts) with increadibly quick lead times. Do you have manufacturing requirements and need a professional manufacturer?