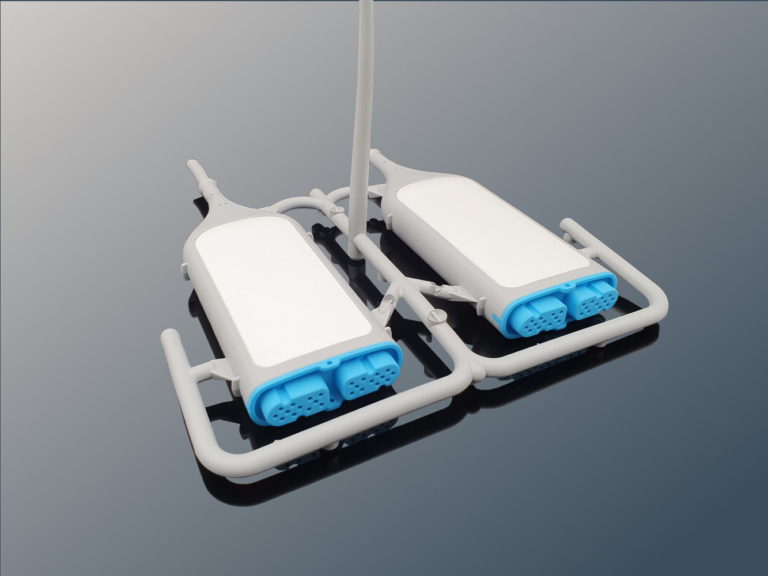

Delivering all facets of medical device manufacturing from medical device plastic injection molding to assembly and packaging in a Class 10,000/ISO7 Clean room environment.

We support medical device companies with an end to end solution by carrying out their entire supply chain. This ranges from improving product design for manufacturing purposes & engineering to molding, product assembly, and its packaging.

VEM’s Medical & Healthcare Tooling Factory encompasses an extensive industry experience in the medical device manufacturing industry. We understand the manufacturing standards that need to be followed which is why we ensure to adhere to the ISO 13485 production standards.

The Class 10,000 Clean Room includes injection machines for medical devices, assembly and subassembly units and machines as well as final packaging facilities. The cleanroom is equipped with the latest technology such as QC equipment and robots to ensure smooth mass production capacity. Along with the production facility, we also develop validation protocols, testing procedures and process improvement studies to ensure highest quality and competitiveness.

VEM Tooling continually invests into engineering resources thus, we have the expertise, skill-set and technical knowledge to assist you with your medical device manufacturing across various stages and complexity levels.

Our manufacturing experience and input during an early product design phase has helped our clients to save upon resources and time. By partnering early during the product design phase development, we have eliminated common errors and mitigated redesign issues that may arise due to complexities thus, we encourage medical device manufacturers to partner with us during the product design phase stage.

We also help in establishing an entire assembly along with testing procedures. All the procedures that are established are optimized to deliver the best, in terms of quality and an efficient turnaround time.

We also help in the maintenance of documentation that is required for medical device molding.

At VEM Tooling, we build medical device molds in our factory units due to which we have complete control over quality. To design and build the mold, we either follow customer standards or use our VEM standard design.

We ensure to only use imported and certified steel as well as the standard components you prefer to build your molds. This guarantees us to manufacture medical device molds of the optimum quality that medical device manufacturers should adhere to.

This also ensures better lead time and enables us to incorporate any type of minor or easy modification that the mold may require.

VEM Tooling also ensures to deliver spare parts and the replacement parts of the medical device molds at the lowest lead time. Additionally we can guarantee the quality of the replacement or the spare parts is as per the quality standard.

You will experience fast and direct communication which ultimately leads to a seamless and smooth manufacturing process.

VEM Tooling’s Thailand Plant is ISO 13485 certified and has an ISO 7/Class 10,000 cleanroom after ISO 14644-1:2015 certification. Our mold design, engineering and manufacturing team follows rigorous standards to make medical device molds.

Throughout the process, we follow standard protocols and keep continuous improvement efforts to the highest level. This allows us to remain highly competitive in terms of quality and lead time.

We are ISO 9001:2015 and ISO 13485:2016 certified.

With our cleanroom we reach the ISO7 / class 10,000 standard of 14644-1:2015.

Medical device manufacturing requires that every device and equipment is manufactured according to the standardized quality and without any compromise to the safety. Thus, Medical Device Injection Molding should always be carried out in ISO certified cleanrooms or whiterooms. This ensures that medical devices are protected from all types of dust, aerosol particles, airborne microbes and chemical vapors or any other contaminants at every development stage.

At VEM Tooling, we focus on providing precision, accuracy and quality for our medical device manufacturers. We are one of the few medical device injection molding companies that provides the entire supply chain with manufacturing capacity in cleanrooms and whiterooms.

Medical Device Manufacturing at VEM is an assured way to a successful mass production of quality medical devices.

All the equipment in the clean room at VEM is equipped to be highly automated with robotics. This aids our engineering and manufacturing team to reduce production errors. It also optimizes the manufacturing cycle thus, boosting productivity.

VEM Tooling is committed to providing our clients with the best medical device manufacturing service. At VEM, we also ensure that you receive clear and timely communication. These are the core values at VEM.

Our emphasis lays upon delivering a quality product that meets all the regulatory standards at a cost-effective price.

To better understand how VEM Group serves the medical device manufacturing industry contact us or request a quote today. We are looking forward to becoming your trusted medical device injection molding partner.