Injection molding outsourcing services in the plastics industry have observed significant growth! This is due to the ability of contract manufacturers to deliver high-quality plastic parts within a quick turnaround time. The outsourcing services help the manufacturers in providing reliable solutions to produce high-quality injection molded components.

Plastic injection molding outsourcing services can be applied to a wide array of industries and they can be utilized for the production of small, medium, and/or large components.

Today, outsourcing services play an essential role in mapping both, the immediate and futuristic goals of businesses. Outsourcing services provide effective operational tactics. It has grown substantially and can now be seen dominating operational processes across various industries. In this article, we will learn about the 3 types of outsourcing services and their suitability for various businesses.

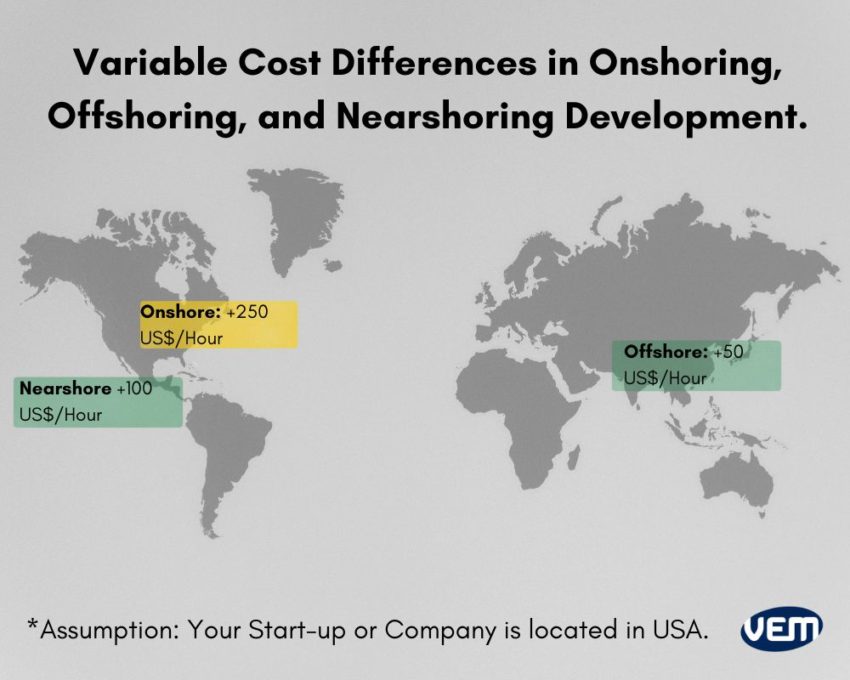

Outsourcing services is undoubtedly a cost-effective technique! Earlier, i.e. pre-Covid, it was very common to outsource offshore. Offshore development enabled organizations to attain high-quality services at low operational costs. However, Covid made many manufacturers realize the dependency of relying only on offshore development. For instance: Many manufacturing companies were not able to get the required components or materials which lead to product shortages. This was also seen partly due to government restrictions.

The outsourcing trend in the 1950’s to 1960’s was that of onshore development. A great example of onshore development in the 1950’s to 1960’s would be GE’s Appliance Park in Louisville, Kentucky. After World War II, GE anticipated sales growth in appliances; however, the assembly plants were all across the United States, thus, in 1950, GE consolidated those operations into a central location, a site known as the Appliance Park. This was majorly the trend during the 1950’s and 1960’s but there was also the onset of offshore trend between the 1950’s and 1960’s.

The offshore development trend started developing in the 1950’s and 1960’s and was largely put in effect by various companies between the 1970’s to early 2000’s. During these plastics industry trends, several U.S. companies opted for offshore development to outsource manufacturing production through contract manufacturers to emerging Asian countries. During this era, offshore development increased exponentially in China, India, Taiwan, Thailand and various other developing nations. While the offshoring trend established operations for businesses in an easy and efficient manner for nearly half a decade, it’s today not the most practical solution for every manufacturer/business. In addition, there were various challenges faced during the Covid which made many manufacturers undertake another approach i.e. Nearshoring.

The mid-2000’s have seen a new trend with manufacturing industries i.e. the ‘Nearshore development’. Today, various types of businesses and manufacturing companies are interested in onshore and nearshore development.

Nearshore development in 2022 provides the businesses with a greater sustainability, technological advancements, low costs, onsite visits and flexibility. In addition to the nearshore development, onshore development too is currently growing in the U.S though it has not reached widespread acceptance.

Outsourcing plastic injection molding services offers 3 major benefits to manufacturers: Knowledge base, work offloading and cost saving.

Outsourcing development involves the transfer of operational activities of value-based suppliers. The aim here is to shorten the supply chain and execute an internal reduction of services that are supplied internally. Outsourcing is usually operated with the concept of a business removing a manufacturing department by moving its factory elsewhere or utilizing another company instead.

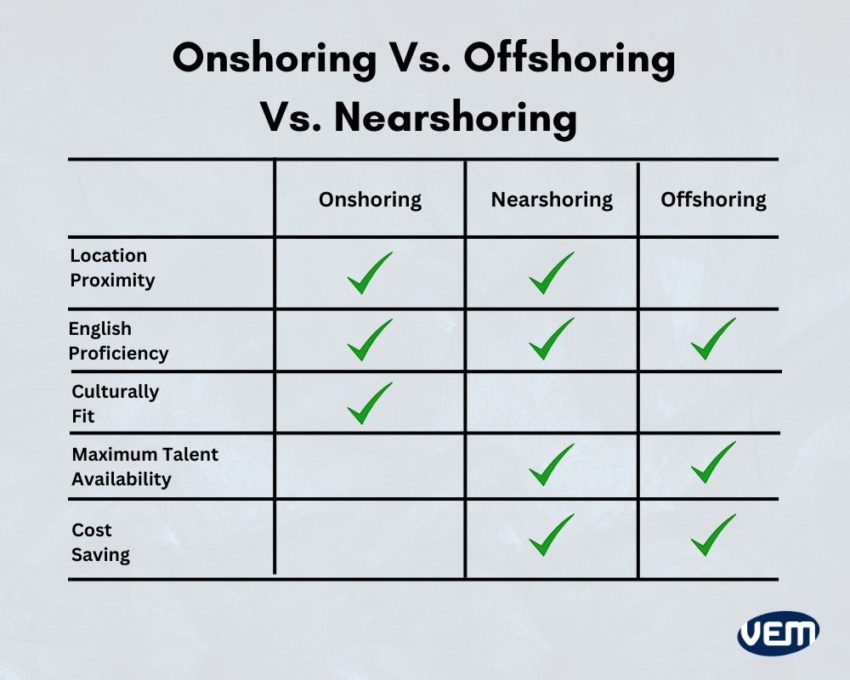

Today, outsourcing services are categorized into 3 types: Onshoring, nearshoring, and offshoring. Each of these trends has unique aspects, benefits, and drawbacks.

Onshoring is a type of outsourcing service that is geographically the closest to your headquarters location. If you’re setting up your company in California and your manufacturing partner is in California, then this type of outsourcing is referred to as onshoring. Choosing onshore development is a great choice if you want your partner team within close vicinity and have frequent onsite check-ins.

Onshoring may be a requirement for companies that are information-sensitive. There may be certain business types that wouldn’t want their information to be available in other countries. In such a case, on-shore development is a priority and not a choice.

There are various advantages and disadvantages to Onshoring:

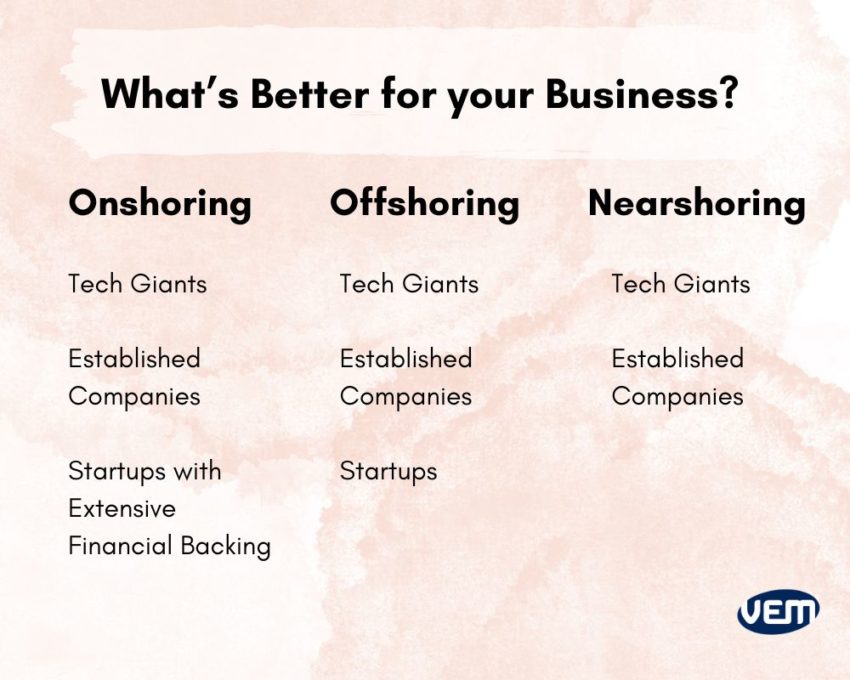

Onshoring can be expensive and thus, onshoring is generally a common practice among tech giants or startups with established industry founders.

Nearshoring is also referred to as ‘ The Golden Mean’ as this type of development has various advantages. Nearshoring is a type of outsourcing that is located near you but is not as accessible as onshoring development. Nearshoring is a great option when you want to reduce costs but don’t want to compromise on the distance.

One of the major advantages of nearshore development is that it also helps to reduce transportation costs especially when you are trying to manufacture huge, bulky products such as cranes for construction. If you decide to outsource via nearshoring, you can transport them easily by road.

An example of nearshoring would be if your location is in California but your manufacturing partner is in Mexico or Brazil. Nearshore outsourcing definitely reduces costs, and in addition, you’ll have your manufacturing partner close by.

An off-shore team refers to a team located in a different country, offering services to your company. This is a common way of outsourcing and is being used by many companies. An offshore development team supports you from a distant location. This is the most cost-effective type of outsourcing, at least considering the direct costs involved. An example of offshoring development would be that your office is in the U.S and your partner team is in India or China. If your company does not have any staff in those countries, it is advisable to use a sourcing partner. With a Google search you can find several sourcing partners for each country, such as Leeline Sourcing for China.

The biggest disadvantage of offshore development is the time zone difference. It can be solved by defining a common communication framework but it will not always be available.

The type of outsourcing you choose is dependent upon a variety of factors such as set goals, available resources, or certain other requirements.

Each of the above outsourcing types has advantages and disadvantages thus, a universal suggestion cannot be recommended. Even though offshoring significantly reduces costs and may seem to be the best solution for saving personnel expenses, operating in different time zones may lead to a whole new and unexpected range of costs. On the other hand, nearshoring development can include onsite visits and frequent communication. Thus, it might be a better solution for coordination.

While offshoring has been a cause of concern for many, in the manufacturing industry ‘nearshoring’ has implemented itself well. This change, along with a reexamination of supply chain practices, is shifting the processes of modern facilities.

Global uncertainties due to changes in the transportation fields as well as other factors have led companies to look for companies they can build reliable partnerships with. Many injection molding companies were reevaluating their activities because of the high costs and long delivery periods involved with manufacturing parts or finished goods abroad; thus, they decided to import and export from geographically closer areas.

Companies that benefit from nearshoring attribute their performance to faster distribution, dependability, and cost savings. You should note that developing long-term partnerships with injection molder partners that can collaborate with you in the product production process and help with the design for manufacturability is extremely advantageous.

Plastic injection manufacturers can help their customers identify materials that are apt for their projects. These decisions are based on their design specifications and certification requirements.

We can help you incorporate outsourcing practices into your manufacturing operations. Our plastic injection molding and tooling facility in Mexico and various other locations are dedicated to providing you with a great manufacturing experience and exemplary service.