Have you ever wondered the type of techniques in overmolding or the type of materials that you can use for the overmolding process? This article is your definitive guide to acquiring in-depth insights upon overmolding techniques and processes.

Overmolding is also referred to as ‘two-stage’ injection molding. Overmolding is a type of injection molding process in which two or more components are molded over one another. The overmolding technique primarily involves covering the substrate which is the first material either partially or completely by the subsequent materials.

The uniqueness of the overmolding process is such that various materials can be seamlessly combined into a single product or part.

Some of the most common examples of overmolding are power tools that often use textured materials to add an ergonomic grip. Another example includes manufacturing car tail-lights that encompass multiple color parts.

The overmolding process generally includes a rigid, plastic-base overlaid with a thin exterior layer. This can be done using either a single-shot (insert molding) or two-shot (multiple-shot molding) technique.

The most important aspect of the overmolding process is to ensure that the melting temperature of the substrate is considerably higher than the second molding material.

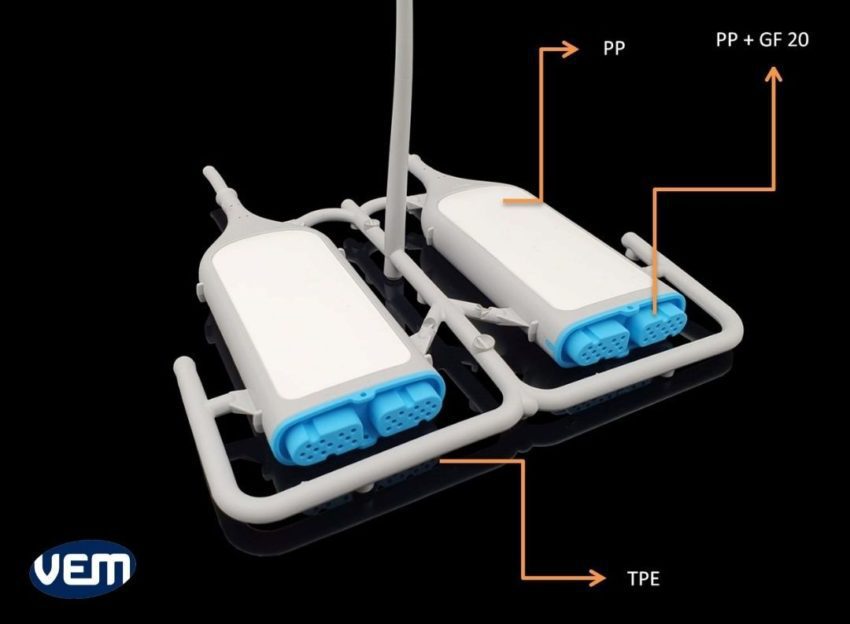

There are typically 4 types of combinations that we can implement to develop a product. These are listed below:

You must however, note that product developers and engineers are not always restricted to using only 2 materials in the overmolding process. If you are unsure which materials can be combined, don’t hesitate to reach out to us. Our engineers and design team can guide you to combine various materials that are compatible to develop a durable product.

The total cost of insert molding is low as compared to the other 2 techniques which is why it is widely known as a low cost overmolding technique. The Insert Molding process is a 3 step process:

Manual overmolding process :

The overmolding process can also be performed manually by taking out part of mold 1 from the injection molding machine and placing it in mold 2. This is typically done for small batches of up to 10,000 pieces.

Manual overmolding is not suited for large scale productions as it is constantly manual. Thus, it is not cost optimized for mass production however, it is the best solution for smaller batches.

While the 2 terminologies are very interchangeably used, there are some differences. Overmolding combines multiple materials seamlessly into a single part or product whereas insert molding requires pre-placement of an insert which is typically metal, in the tool. After which, the injected plastic flows around encapsulating the insert. This creates a single molded plastic piece.

Generally the final part that is made using insert molding is more durable than the one made by secondary assembly.

Two-shot molding or 2K Injection Molding is a type of overmolding technique. They are essentially similar. We must note, however, that two-shot injection molding is often used for huge production runs as opposed to smaller production runs.

At VEM, we help you choose between the 2 types. Finding the most appropriate solution for your needs is always our main priority. We ensure to critically evaluate each step of the manufacturing process and your product requirements.

One of the most important steps in overmolding and the product development process is the ‘material selection’ stage. It is imperative to choose the best-suited plastic resins for the application as this will ensure the combination of required material properties to guarantee a durable and optimally performing product.

It also has the ability to alloy with polymers such as high-density polyethylene (HDPE) and low-density polyethylene (LDPE). More details in this dedicated article about ABS.

HDPE is best suited for parts and products where durability is of the utmost importance such as corrosion-resistant pipes.

We encourage our customers to involve us early on in the process so that they can discuss material combinations. By getting involved in the early phases of the manufacturing cycle, we can help you with the best material selection for your products.

Overmolding has an expansive scope in improving the aesthetics and functionality of a product. It can be used to either add colors, textures, shapes, or improve upon the functionality of the product.

Overmolding process is a technique that when applied, alters the physical properties of the part or product to suit the requirements that may vary from upgrading the functionality of the product to enhancing the aesthetics in order to differentiate it from the competition. The overmolding process is typically used to manufacture innovative products to promote user experience and boost sales. Manufacturing modern and new designs also helps to differentiate a product visually from competitors.

The overmolding process can be applied to a myriad of industries and has diversified applications. Some of these applications are listed below:

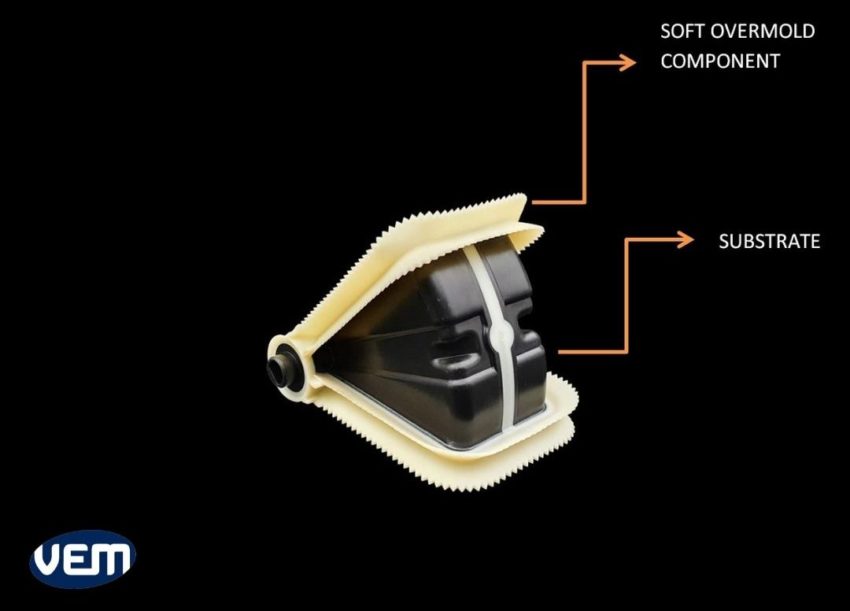

Medical overmolding is one of the most specialized applications of overmolding. Many medical devices are required to have a rigid substrate with a soft overmold. By utilizing medial overmolding, VEM can produce a range of medical devices, and high performance equipment that has a non-slip design.

When it comes to medical device manufacturing, we ensure to conform to the stringent requirements of the medical manufacturing industry to manufacture the highest quality product. Our mold design, engineering and manufacturing team follows rigorous standards. Our Thailand plant is ISO 13485 certified and has an ISO 7/Class 10,000 cleanroom after ISO 14644-1:2015 certification.

The overmolding process is also a very popular injection molding technique in the automotive industry. It is often a preferred technique to produce handles, components of car seats and headrest, car handles, energy absorber mounts, car hood, and dashboard accessories.

Prior to overmolding, these components were manufactured either solely or largely with metal to maintain durability. Post over-molding, these components can be manufactured to be not only durable but also light-weight and desirable for the consumer.

When molding automotive products and parts, it is imperative to take into account the numerous factors that are related to vehicle movement. Today, molding automotive products and parts requires material behavior and manufacturing processes to be considered at an early design stage. This helps us to streamline any obstacles that may arise in manufacturing.

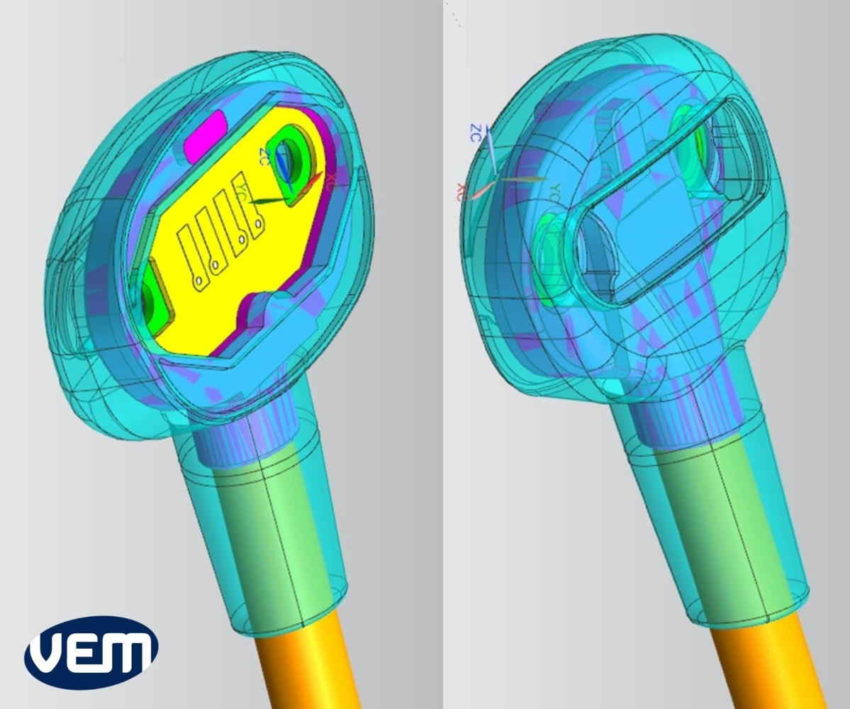

Another industry where overmolding techniques are very extensively used is the electronics industry. Many parts are over-molded in the electronics industry to seal the sensitive electronics components and connect it with the cables.

The most significant overmolding applications in the electronics industry are PCB, thermostat and circuit board overmolding. In this type of overmolding, electronic assemblies are positioned within a mold. Once they are positioned, they are then injected upon with molten plastic which then hardens into a protective layer. This ultimately reduces the damage risk by sealing the junction between the wires and connectors. Almost every electronical product that you can see has some degree of overmolding involved in their production. Just take a look at your USB charger or HDMI cable, just to name a few.

The primary reason to use overmolding techniques is to develop more innovative products and complex designs but in addition to that, it offers various benefits that can significantly impact your manufacturing cycle.

Though there are various benefits of developing products with overmolding techniques, there are a few disadvantages that we must note as well. Some of these are listed below:

VEM provides end-to-end solutions in plastic overmolding. We have 7 locations across the globe with state-of-the-art tooling facilities. Our engineers and designers can help you create high quality molded parts and products. To better understand how VEM tooling can serve you, in terms of overmolding, contact us or request a quote today.