Today, product and part traceability has evolved to be a ‘must-have’ aspect in the manufacturing and retail/logistics industry. The development of technology in this segment has helped to streamline and avoid various manufacturing and operational issues.

Product and part traceability has enabled both, accurate information and precise identification of products. It has helped to minimize product recalls, enhance quality control, optimize production processes, and avoid counterfeit products. In this article, we explain part and product traceability in manufacturing in-depth.

Product and part traceability is identifying and tracking products across a supply chain.

This process helps to track products and parts from the manufacturing unit to the final consumers.

You should note that the parts that are produced within the same batch code will be more or less of the same quality thus, it’s easier to locate all the products that may have a defect or deformation. If there’s an issue with one part or product from a particular batch, you can easily identify all the products from the batch and locate their origin or where it has been sent.

Product and part traceability increases supply chain visibility by organizing its data.

It consists of logging information in a centralized database to track products at every stage. It is imperative to choose the right marking system to develop a robust traceability solution. You can read more about traceability in manufacturing here.

To ensure that your products are traceable, you need to implement a robust system that follows the product manufacturing journey all the way, from raw materials to processing and distribution. This enables gathering information on various components that are vital for product identification.

The key to precise and accurate information via product and part traceability is having a centralized system. There are various platforms and technologies that help to create a centralized traceability solution which is why it is more achievable than ever!

The main aim of product traceability is to track the movement of the product across the supply chain with the help of a unique identifier. The unique identifier scans the product, along with its box or pallet. The scanning can be done at several stages of the production cycle.

In contrast to product traceability, logistics traceability is used to follow the products along with their box or pallets after they leave the manufacturing unit. Logistics traceability follows logistical assets such as cargo and trucks through air, sea, and land. It makes use of GPS sensors to keep track of the products.

Product and part traceability is crucial to protecting the consumer and is about easily recalling a defective or deformed product back from the market. In addition, it increases awareness of the product’s origin and its conditions among the customers. Let’s understand the impact of product and part traceability in detail:

One of the most challenging aspects for manufacturers lies in the ‘middle’ of the supply chain. Here, the products are either with the distributors or the channel partners which poses a substantial data collection challenge.

Through product and part traceability, manufacturers can make use of the data to determine if their distribution network is functioning aptly. They can also locate whether the distributors are breaching any rules by selling to unlicensed markets.

One of the factors that have made it challenging to receive distribution data is that they generally have a standardized approach for all the brands that they distribute for and thus, they do not use any specialized tools. In addition, there were technological restrictions with respect to data links with the ERP for each distributor. Modern traceability solutions and systems have addressed these limitations in the following ways:

Product traceability has had a significant impact on the management of distributor inventory and demand forecasting. The advancement of technologies in traceability has enhanced these concepts. Let’s understand this further:

Without product and part traceability systems, it was impossible to trace damaged goods back to the source. Product traceability systems have made it possible to locate recalled goods and follow them through their supply chain.

In modern traceability systems, the distribution information for each product or part is available through unit-level tags. These tags include various data such as the batch, lot, and serial numbers. These tags also include shipping data from various points in the supply chain. This has enabled a channel for both, client engagement and supply chain traceability data at the unit level.

There are various regulations for several industries that mandate products to be traceable to the unit level and the only way to achieve this is via serialization. Serialization includes printing and labeling unique codes on products and packaging. Let’s understand the various regulations that are required for product serialization:

Combating counterfeits is an ongoing struggle for the manufacturing industry. It poses challenges to the already complex supply chain. Counterfeit goods don’t just hurt the business or present the consumer with low-quality goods but they also put the end-user at risk and sometimes, even their safety is compromised. Thus, there is an increasing need for companies to be able to verify the legitimacy of their products.

Counterfeiting goods poses a risk to any business from any industry! Whether it’s the fashion or the cosmetics industry, or whether it’s the medical / healthcare industry, counterfeiting need to be combatted! Let’s take a look at an instance that can be applied to most industries: The refilling/filling of lookalike packaging of authentic brands with counterfeit products can pose a risk to the end consumer. This may include medicines, alcohol, and beauty products. Following is a list of various industries where counterfeit goods are a potential problem:

Product traceability and marking technologies play a key role in combating counterfeit goods! These technologies are designed to authenticate the product properties and verify products as they move through the production cycle. As a manufacturer, you should note that all the products in the supply chain should be marked to be traceable to ensure authenticity. This reduces the risk of the products being tampered with, thereby reducing counterfeits. Through product traceability, you can ensure that your products are registered, tagged, and traceable. It establishes parameters that make the branded product easy to distinguish from the counterfeits.

The most important component of product traceability is the placement and identification of unique codes. Integration of these codes is today, only possible as these codes share a standardized language. The most widespread unique code systems that are used for product traceability are:

EAN/UPC Barcodes are one of the most popular and widely used product identification technologies. This system uses a common and standardized language to create unique codes through a number series that has equivalent bars to identify the product.

The coding standards for different types of information that need to be linked to each product are based on GTIN, abbreviated for Global Trade Item Number which is, established by the GS1 organization. The GTIN number may be supplemented with additional information such as the batch, Shipment Identification Number (SIN), or Serial Shipment Container Code (SSCC).

Radio-frequency Identification abbreviated for RFID tag transmits data via radio frequency waves. These tags are not as popular as the barcodes as they are more expensive. The main advantage of RFID tags is that they are more secure as it takes specialized equipment to read the data.

QR codes create digital identities for products. The data in the QR code can include specifics such as the origin of raw materials, where and how the product was processed, and how it reached the consumers or the retail shelf.

QR codes can be scanned via a smartphone’s camera. There is no requirement for specialized devices and thus, most potential customers can interact with QR codes. The only problem that most people experience with QR codes is trying to get the QR code in focus and its correct size so that it can be easily recognized by any smartphone device.

NFC, abbreviated for Near-field communication, is a popular wireless technology that is used to transfer data and share media between two devices that are in proximity.

NFC tags do not rely on a phone’s camera, but they require a smartphone and software for a user to interact with them. This compatibility complication is one of the main cons as it does not always facilitate user experience however, today, this is becoming less of a problem due to the widespread adoption of NFC in modern smart devices.

Once a standard coding system has been established for the products, it is necessary to have devices that can capture and record data. These devices serve as a bridge as they gather and record information. This information then transmits the data to the software.

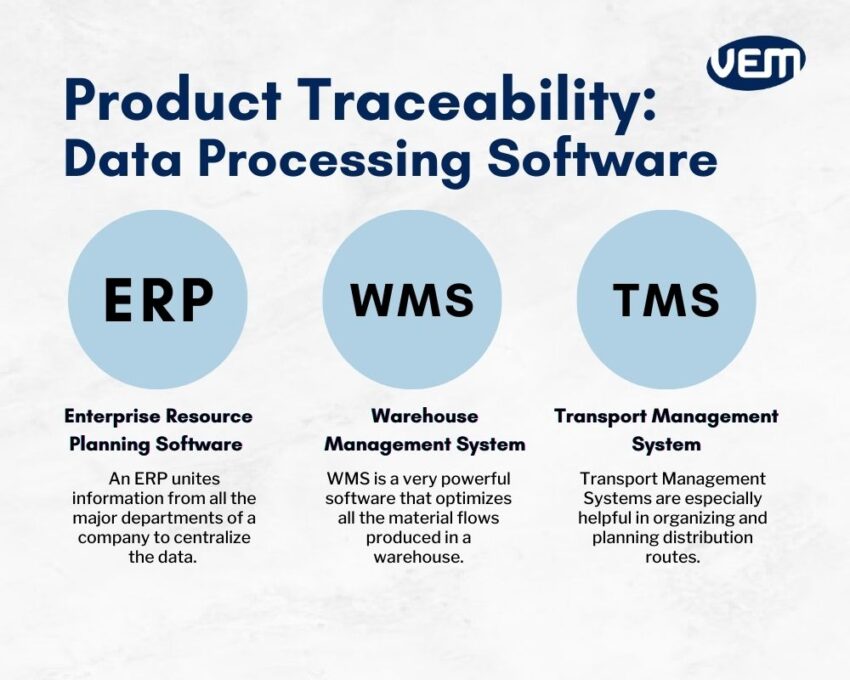

An integrated system is required to bridge the physical movement of goods across the supply chain data into an information flow and that is only possible through data processing software. This software centralizes the data and processes them. The main types of software used in traceability systems are listed below:

Enterprise resource planning software is a type of business management system that is integrative in nature. It is usually a base system, where information from the main areas of the company converge. An ERP unites information from all the major departments of a company such as sales, accounting, production, stock management, human resources, etc. to centralize the data.

A warehouse management system is a very powerful software that optimizes all the material flows produced in a warehouse. In WMS, each phase is registered and the software communicates to the ERP and other software through which a manufacturing unit operates.

Transport Management Systems organize and plan distribution routes. These are especially useful in e-commerce shipments. To achieve greater agility, TMS software is often integrated with WMS to facilitate information exchange and consolidate labeling.

Centralized technologies that we discussed above provide accurate counterfeit product detection however; there is a new technology on the rise that we would like to discuss and that’s using blockchain technologies to improve transparency.

The aim of blockchain technology is to address the various management issues that are experienced in the current supply chain sector such as paperwork, counterfeiting, and product mislabeling. In addition, there are many products with ingredients that are illegally sourced and these often bypass the existing supply chain management. Today, blockchain technologies are being used to build a more transparent supply chain through a data infrastructure that securely tracks and traces products.

By combining the existing technologies with blockchain, companies can securely and reliably track and trace all the transactions that take place across the supply chain. The decentralized nature of blockchain provides greater transparency thereby, proving to be an effective anti-counterfeiting measure. You should note that even though blockchain-based traceability is trending, it is still taking strides in its development.

Let’s understand how blockchain technologies help to achieve product traceability further:

Blockchain technology is basically a digital system or can be considered a decentralized ledger. This system is designed to record transactions between multiple parties to ensure transparency however; it does so securely and in a verifiable and immutable manner. The transaction records that are noted in this system help to monitor every phase of the supply chain and the business transactions. Blockchain technology helps to track the movement and document information while showcasing previous records.

Essentially, blockchain technology includes a ‘chain of blocks’ in which each block refers to or represents a collection of transactions. These transactions are distinct from each other. The blocks are added to the already existing chain of blocks through a cryptographic hash function.

If you need to access a particular block’s data, then you need to enter the decrypt keys of the hash function. The decrypting keys will give you access to the data of a particular block. Blockchain technology thus offers a comprehensive audit trail and as it decrypts the information, it allows the safeguarding of the various identities, production processes, and other confidential information across all stakeholders of the supply chain.

Walmart is one of the top leaders in supply chain management and is now using blockchain technology to create automated processes. Walmart has specifically adopted this technology to handle invoices to include various data points. These data points need to be accounted for in each invoice and this is where blockchain technology has been particularly useful. It has eradicated discrepancies and reduced reconciliation efforts that were often labor-intensive and time-consuming. A blockchain network resolves various issues by introducing a single source of credible information that’s immutable. You can read more about this particular case study here.

Product traceability systems enable manufacturers of various industries with valuable digital mechanisms. The implementation of these systems is critical for safety and regulation compliance. Let’s take a look at which industries consider product traceability as critical and apply it more often than others:

One of the industries where product traceability is not just a good-to-have aspect but a necessity is the food industry! A potential food safety problem can be identified by either the business itself, a government agency, or a customer. In this industry, traceability enables businesses to take corrective actions such as product recalls. If there is a food safety issue, such actions can be implemented quickly and effectively.

An effective traceability system in the food industry helps to isolate contaminated products and prevent them from reaching customers. Food traceability processes help businesses to minimize trade disruptions and enable them to be compliant, improve inventory management, and maintain a positive brand image.

Traceability systems in the food industry are essentially the same tools that help you to record and track a product across the supply chain. It allows monitoring of perishable inventory and helps to find information about the type of raw materials used in a product. This may be either for a batch or an individual ingredient.

The next industry where product traceability is of prime importance and is a matter of complying with the regulations is the healthcare industry. It is one of the sectors where, every information is vital and you ought to know the packaging date, the batches the product belongs to, and the expiration date.

In the healthcare industry, product traceability processes enable businesses with complete visibility regarding the movement of prescription drugs and medical devices. Through traceability systems, one can identify the history of the transfers and locations of a product from the point of manufacturing via backward traceability and one can also track the product route towards the patient or the customer via forward traceability. One of the traceability technologies that are often used in the healthcare sector is RFID technology which helps in medical supply control and access control of healthcare personnel. Using RFID tags also makes inventory management easier. Due to automatic identification, information can be obtained in real-time which in turn, improves stock management and ultimately, guarantees patient safety.

The next industry that has taken advantage of product traceability systems is the retail industry. Different types of companies such as large fashion giants, medium-sized drugstores, etc. have incorporated product traceability systems such as RFID tags on their products.

RFID technology offers various advantages to retail sector companies such as stock visibility and greater control of the supply chain. RFID is the perfect solution for businesses that would like to offer transparency to their customers. It also enables complete product visibility, from its origin to its sale, thus enabling reliable and real-time information on the product’s history. This data enables them to efficiently manage their distribution chain and quickly correct any problems that may arise.

Product traceability has made a huge impact on authenticating products for the cosmetics industry. Counterfeit cosmetics pose a real threat to both consumers and brands. The ingredients that are used in counterfeit products are often low-quality and they directly hurt the business of the brand. Counterfeit cosmetics mimic to replicate the originals which disrupts the brand’s sales and its reputation.

Product traceability helps to tackle the issue of counterfeit products through unique digital product identifiers. These unique identifiers capture real-time data at every stage of the supply chain, thus empowering companies by mitigating financial aspects. In addition, unique identifiers establish direct communication with the customers and in case they come across and identify a counterfeit product, they can report it to the brand’s customer care. Thus, the product traceability infrastructure enables brands to invite consumers into their authentication process.

Current systems in VEM provide unmatched transparency during the whole manufacturing process. Especially the traceability during the mold making process is something we are particularly proud of.

Working with many large international partners, we are always open to implement new ways of improving traceability, according to requirements. If you have an interesting project at hand, be it plastic manufacturing, assembly or mold making, shoot us a message.