Supply chain management includes all manufacturing processes such as planning, sourcing of raw materials, procurement, manufacturing, delivery, returns, and logistics. Today, supply chain management is adopted and implemented by various businesses in distinct industries. It has become integral to the business strategy as it helps to boost the competitive advantage of any company! On the other spectrum, globalization of the supply chain and its management introduces various types of risks that can hamper the safety and continuity of businesses.

Disruptions can arise quickly and bring an efficient supply chain to an immediate halt! A single disruption can lead to losses in millions, and sometimes even, billion dollars. Various types of disruptions can also lead to a domino effect which can severely affect operations and lead to delayed shipments, productivity decrement, and affect product quality.

There is a wide gamut of risks such as natural disasters, operational disasters, and financial and reputational risks that need to be managed, and thus, it is important to implement a robust supply chain risk management program to ensure that such issues are mitigated. A supply chain risk management strategy helps businesses to operate more efficiently, and enhance customer service. In this article, we discuss the supply chain risk management factors, its processes, and how you can implement them for your business.

Supply chain risk management, abbreviated as SCRM, is a thorough and in-depth process of identifying various types of risks that can arise in the supply chain. It furthermore, assesses and establishes mitigation methodologies. SCRM is basically a process of creating a strategy to identify, evaluate and assess, and mitigate risks in your end-to-end supply chain.

SCRM includes understanding your supply chain thoroughly, conducting both internal and external audits, and developing effective crisis responses. An excellent SCRM program helps to prevent bottlenecks and ensures that all processes are operating, both legally and ethically.

The very first step is to identify every potential risk in your supply chain. In this phase, you should account not only for risks in tier 1 but also account for tiers 2 and 3 since that’s where the majority of disruptions occur.

The next phase is to make the obtained data ‘actionable’. In this stage, you need to assess the data to understand the impact that the potential risk can pose on your supply chain.

At this stage, you should also note what are the risk priorities specifically, for your company. You should consider creating a risk assessment matrix where one axis should be disruption impact and the other one should be the likelihood that it occurs. Once this has been established, you can start mapping out each event to create a matrix that will guide your strategy.

The next phase is the mitigation of risks! There are 2 types of effective risk mitigation plans. These are listed below:

An SCRM process requires a framework that can balance both operating expenses under standard settings as well as under extreme limitations. Let’s understand the 4 major steps that encompass the SCRM process:

There are various types of risk hazards in the supply chain and they need to be identified and assessed accurately. These hazards can be operational and business changes, global economic instability, unreported financial concerns, extreme weather changes, and, natural catastrophic issues. Some of these risks are generally difficult to predict and thus, difficult to plan for but all of them ultimately create delays and lead to more expenses.

In identifying risks, it is imperative to learn from the past, observe the current occurrences, and forecast the future. Forecasting the future to identify potential risks requires the team to have an astute sense of observation and ingenuity. It requires attention to detail to note various details such as the company’s location, suppliers, distributors, manufacturers, and retailers.

It is crucial to understand the type and location of every risk occurrence. It is also important to understand the level of impact it can pose on the supply chain. A technique that helps to understand and tackle responses to risk, is known as ‘Risk Scores’

Risk scoring is a type of technique that gains and delivers immediate visibility into issues that require attention. There are various types of risk score methods, but in all the methods, these risk scores are represented in numerical, color, or graphical formats. These representations indicate how a type of risk relates to other types of risks in the supply chain. Thus, it enables resolving the relevant risks, immediately, and at the right time.

It is crucial to establish your own risk scorecard as it gives an excellent snapshot of all the risk elements. Once you have decided on the parameters to measure risk, you can focus on implementing a solution such that your supply chain is monitored continuously. This is especially important because situations change quickly which means that the risk factors are prone to changing as well. At this stage, a proactive monitoring system is key!

The key to developing a successful SCRM program is defining mitigation strategies and response plans. If contingencies for each risk category are not developed, then it is not possible to respond to the hazards that may develop in the future. It is crucial to study every possible scenario and enlist an alternate solution. This may be seen as a laborious and time-consuming task, but you should note that it’s the most effective approach to proactively respond to any type of future risks that may develop.

When you have developed a thorough strategy and considered all the information, you should proceed to develop your own unique supply chain risk management plan. Every supply chain has a unique risk management plan in order to address the risks that are associated with their specific business. Apart from the unique risks, there are some practices that should always be included in your SCRM plan to mitigate risks at a basic level. We have listed these below:

In order to implement the strategies, it’s imperative to get a thorough understanding of the risk factors in SCRM!

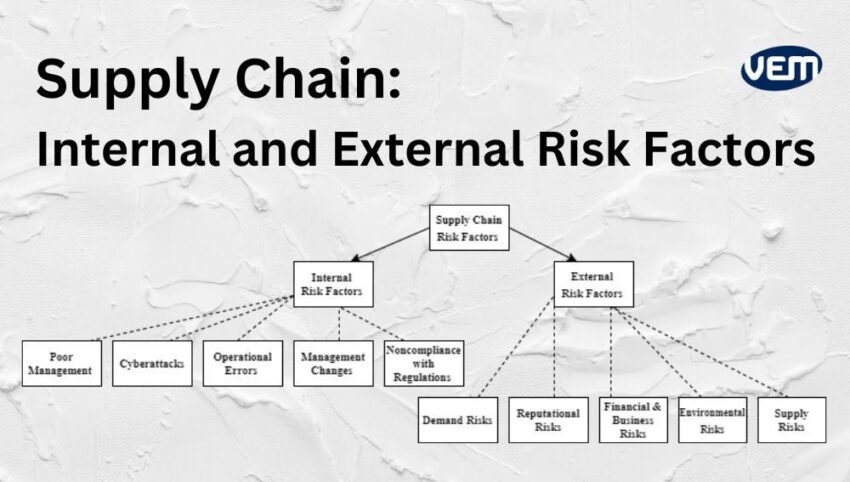

SCRM is a detailed, thorough process, in which various strategic steps are undertaken to not only identify but assess, and mitigate risks. There are 2 types of risk categories – Internal risks and External risks. Both types pose the potential to disrupt your supply chain extensively! Let’s further understand the difference between these 2 types of risk factors:

Internal risk factors for SCRM are caused due to various factors that range from, operational to communication errors. These are also the type of risk factors that are more identifiable and controllable using tools such as supply chain risk assessment software, robust analytics programs, and IoT capabilities. Let’s understand these factors further:

External risk factors are usually posed in supply chains from outside your business. They are thus harder to predict and they typically require more resources to overcome. They can either be triggered by upstream events i.e. through the suppliers or downstream events i.e. through the customers. Let’s understand these factors further:

There are various strategies that have been developed over the years for the risk management of the supply chain. Let’s take a look at the popular strategies:

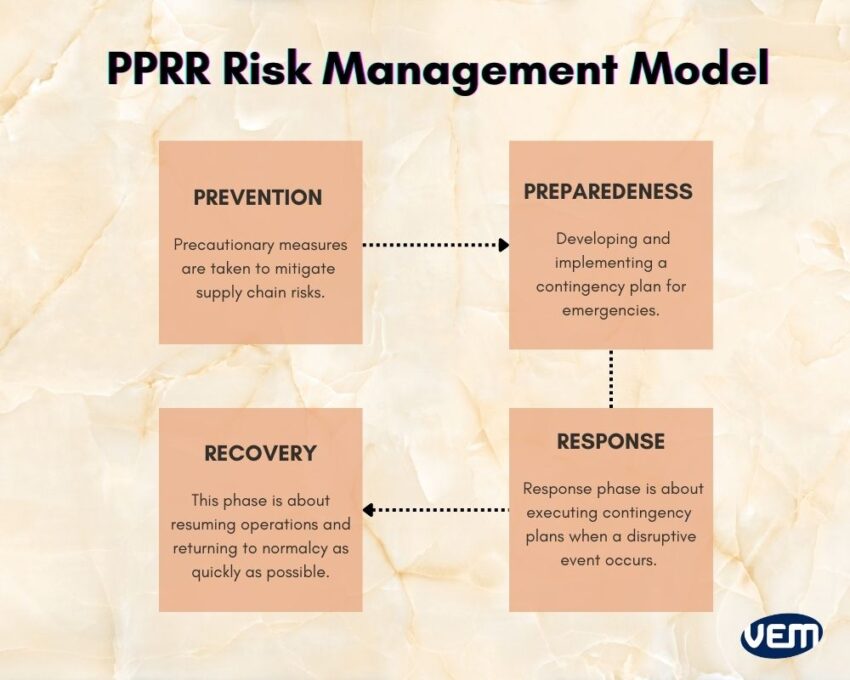

PPRR is an abbreviation for the four phases i.e. Prevention, Preparedness, Response, and Recovery. This model is one of the most popular supply chain risk management strategies.

PPRR risk management primarily helps with business continuity planning. Let’s understand each phase of PPRR further:

One of the ways to manage risks is to consistently monitor your supply chain risk factors. In order to carry the same out, every level of the supply chain should be carefully observed for potential risk indicators.

One of the ways to monitor risk management on a continuous basis is through scalable digital solutions. Such solutions help to automate to provide not only oversight but also valuable intel, safety, and reassurance in streamlining your business operations and supply chain.

The management of operations is one of the major areas to be focused on for risk mitigation in your supply chain but it isn’t the only area. It’s crucial to also build a risk-aware culture and the most effective way to achieve this is, through conducting risk-awareness training at all levels in your company. An effective internal risk awareness training program should ideally, include the following:

One of the strategies to manage risks is by centralizing data. When there are too many solutions in your software ecosystem, it can interrupt the risk management systems. You should consider investing in a comprehensive solution that centralizes your data. Centralization of data helps it to be organized which makes it easier to harness data analytics, predictive insights, and data sharing.

Implementing supply chain risk assessment software is primarily strategizing to take a proactive approach toward risk management! Risk assessment software provides greater visibility into the supply chain structure. Such solutions are able to identify weak points in the supply chain. They are also able to receive data-driven insights which can be turned actionable, and you can work towards strengthening your supply chain.

Supply chain network mapping is the very first step of SCRM but the next strategy that can be implemented is conducting comprehensive and regular stress tests. Conducting these types of stress tests is the best way to check for vulnerabilities that may be hidden deep within the supply chain.

You should consider implementing identical technologies for different components. This strategy allows greater flexibility in case of a disruption. The uniformity of the same software across the network enables better communication between systems and reduces any inefficiency that can be caused due to isolated data.

It’s imperative that manufacturers have a logistics contingency plan. Such a plan ensures business continuity in the event of supply chain disruption. Let’s take a look at some of the tips to create a contingency plan:

It is crucial to have a detailed mapping of supplier relationships. This data is particularly important to risk management professionals so that they can use it to gain insights in order to effectively monitor and mitigate any type of risk.

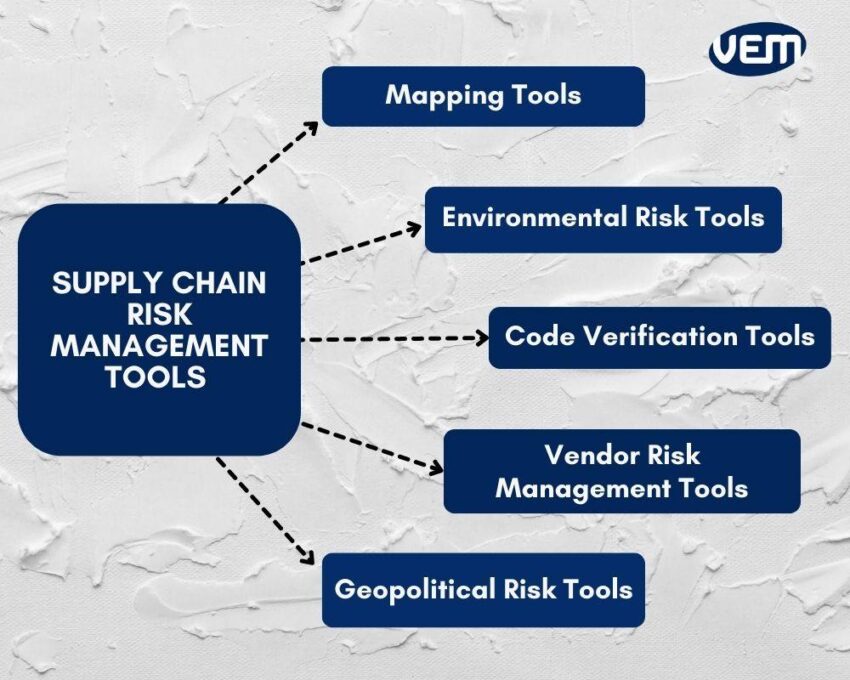

It’s simpler to map tier 1 suppliers but it gets complex when you want to map the suppliers’ suppliers. In order to achieve true visibility, mapping should be done to the tier 2 and 3 levels. Many businesses rely solely on employees to create and maintain this data but it often leads to errors and missed connections. Thus, mapping tools are one of the most important management tools in SCRM.

Environmental risk tools help to track any type of environmental risks that may arise and can affect shipments and logistics. These tools use a combination of real-time updates, historical and forecasting data to gain detailed risk insights quickly.

Today, organizations are leveraging artificial intelligence and big data to predict weather events quickly. This enables them in effective decision-making.

Cybercriminals can often make use of weaknesses in your systems thus, it’s crucial to first locate, and fix weaknesses before they are exploited. This is often caused due to poor coding by software vendors which leads to vulnerabilities in the software. In addition, vulnerabilities can also be introduced by third-party codes into the software and they are sometimes extremely detrimental to the digital supply chain. It is thus important to implement code verification tools in your SCRM plan.

Vendor risk management tools provide various types of automation solutions to manage all aspects of third-party risk management. Many vendor risk management tools not only offer pre-made risk assessments but also offer to upload a custom questionnaire. The results of these assessments align with popular cybersecurity frameworks which further allow you to track risk metrics and compliance gaps.

Geopolitical risk solutions are unavoidable as they feature the complex politics of different countries across the globe. Geopolitical risk tools help to monitor geopolitical data. It further detects any type of potential disturbances that can arise in raw material availability, logistics, and security. It suggests preventive action and thus, focuses on maintaining the stability of your supply chain operations.

Supply chain disruptions are often imminent and in order for your business to respond quickly and effectively to market disruptions, SCRM must be a collaboration between procurement, supply chain, and enterprise risk management (ERM).

Advanced analytics that are today made available through innovative technology solutions enable continuous review of the risks. They also enable seamless integration of SCRM with your business.

AI is a rather novice and evolving technology! Though AI is not being actively used in SCRM, Its use cases are developing constantly. Let’s take a look at some of the current use cases of AI in supplier risk management:

One of the best ways to manage the performance of suppliers is through a supplier scorecard. This helps to strategically rank the various suppliers on the basis of diversity, historical performance, and strategic value to the business. This is an extensively time-consuming task and is subject to change as new suppliers are onboarded. In addition, the scorecard will also need to be updated with new data on supplier performance and any quality issues.

This laborious task can be effectively carried out with AI. Today, various companies make use of advanced machine learning and robotic process automation technologies to capture, score, and update supplier data on a constant basis. Thus, enabling you to adjust supplier strategy instantly.

Supply chains are interconnected activity webs at a global scale. It can be sometimes difficult to obtain accurate data past the second tier. This is especially true in the case of supplier management. Today, this is resolved by applying AI to advanced supplier management platforms. AI algorithms when combined with advanced analytics can give accurate data to the n-th tier. In addition, it can also provide real-time performance updates.

AI is today, particularly used to develop predictive and prescriptive analytics by augmenting reality.

Predictive analytics analyzes historical performance and external data to predict likely outcomes and prescriptive analytics combines enhanced AI with predictive data to give recommendations and solutions to problems. For instance: If you are aware that a certain supplier is likely to be late, then the system will suggest alternative scenarios to match your timeline and quality standards.

A robust SCRM program helps businesses to mitigate risks by integrating tried and tested strategies.

You can explore Supply Chain Risk Management programs through the current systems in VEM-Tooling! We aim to improve all facets of the operations including risk management.